In India’s rapidly evolving e-commerce landscape, the final stretch of the supply chain—the last mile—has become the ultimate battleground for customer satisfaction and operational efficiency. At the heart of this challenge lie last mile delivery stations, the critical nodes where warehouse operations meet the complex realities of delivering packages to India’s diverse doorsteps. These stations, whether serving dense urban neighborhoods in Mumbai or remote villages in Uttarakhand, represent both a significant challenge and an opportunity for optimization.

Warehouse Management Systems (WMS) have traditionally focused on inventory control and fulfillment within the four walls of a warehouse. However, their role is evolving dramatically as the lines between warehouse operations and last mile delivery blur. Today, WMS for last mile delivery represents a strategic integration that extends beyond conventional boundaries to optimize the entire fulfillment journey—from picking and packing to the final handoff at delivery stations and ultimately to the customer’s doorstep.

This comprehensive guide explores how forward-thinking companies across India are leveraging WMS integration in last mile India to transform their delivery stations from potential bottlenecks into powerful engines of efficiency. We’ll examine how modern Warehouse Management System last mile solutions are being reimagined to address India’s unique logistics challenges, the tangible benefits this integration delivers, and the technologies enabling this transformation across urban metros and rural heartlands alike. If you’re new to warehouse management, check out our Introduction to Warehouse Management for foundational concepts.

Understanding Last Mile Delivery Stations

Last mile delivery stations serve as the crucial interface between traditional warehouse operations and the final delivery to customers. These facilities—whether large sorting centers in metropolitan areas or small hubs in tier-2 and tier-3 cities—perform several critical functions:

- Receiving shipments from central warehouses or fulfillment centers

- Sorting packages by delivery routes and priorities

- Allocating parcels to delivery personnel

- Managing returns and reverse logistics

- Coordinating route optimization

- Serving as communication hubs between warehouses and delivery partners

The effectiveness of these last mile delivery stations in India directly impacts delivery speed, accuracy, and ultimately customer satisfaction. Yet historically, these facilities have operated with minimal integration with upstream warehouse systems, creating a disconnect that leads to inefficiencies, delays, and fragmented visibility.

The Indian Context: Unique Challenges and Opportunities

India presents distinct challenges for last mile delivery station operations that make WMS integration particularly valuable:

- Diverse geography spanning dense urban centers and remote rural villages

- Complex addressing systems with informal landmarks often replacing formal addresses

- Variable infrastructure quality across regions

- High volume of cash-on-delivery (COD) transactions requiring verification

- Seasonal demand fluctuations during festivals like Diwali and Raksha Bandhan

- Multilingual communication requirements across 28 states

- Regulatory complexities including GST and E-way bill compliance

As e-commerce penetration deepens across India—projected to reach $120 billion by 2025—the pressure on last mile delivery stations to perform efficiently has never been greater. This is where integrated WMS last mile delivery stations solutions offer transformative potential.

How WMS Integration Transforms Last Mile Delivery Stations

Real-Time Inventory Visibility at the Station Level

The foundation of delivery station optimization begins with accurate, real-time inventory visibility—knowing exactly what items are available, their location within the station, and their status in the fulfillment journey. When WMS integration with delivery hubs is properly implemented, this visibility becomes seamless and automatic.

Modern WMS solutions extend inventory tracking capabilities from traditional warehouses to last mile delivery stations, providing:

- Real-time package tracking from warehouse receipt to delivery station sorting

- Automated verification at critical transfer points

- Immediate identification of misrouted or delayed packages

- Dynamic inventory allocation based on priority, route, and delivery commitments

- Exception management alerts for station managers

For example, when Omneelab implemented integrated WMS tracking across their network of 85+ fulfillment centers and numerous delivery stations, they achieved 99.5% inventory accuracy at station level—significantly reducing the “where is my order” queries that previously consumed customer service resources.

Enhanced Station-Level Operations and Workflow

WMS and delivery station efficiency goes beyond inventory visibility to actively optimize internal operations within these crucial facilities. An integrated WMS brings warehouse-level operational excellence to delivery stations through:

- Directed sorting workflows that optimize labor utilization

- Intelligent batching of packages based on delivery routes

- Prioritization of time-sensitive deliveries (like perishables or same-day commitments)

- Automated quality checks to reduce delivery errors

- Labor planning based on incoming shipment volumes

- Cross-docking capabilities for time-sensitive items

The impact can be remarkable. Flipkart’s implementation of WMS-driven workflows at their delivery stations reduced sorting times by 31% while improving sorting accuracy to 99.8%, directly enhancing their ability to meet delivery promises across various service levels.

Streamlined Handoff Between Warehouse and Delivery Station

One of the most significant benefits of WMS for e-commerce logistics in India is the elimination of communication gaps between central warehouses and last mile delivery stations. This seamless handoff ensures:

- Advanced shipment notifications that allow stations to prepare appropriate resources

- Automated documentation generation including GST-compliant invoices and E-way bills

- Pre-sorted shipments based on delivery station requirements

- Clear communication of special handling requirements or VIP orders

- Real-time updates when shipments leave the warehouse

BigBasket’s implementation of this integration reduced their dock-to-sorting time by 47%, enabling them to extend same-day delivery options to more pin codes even during peak grocery ordering periods on weekends.

Technology Enablers for WMS-Last Mile Integration

Mobile WMS Solutions for Field Operations

The power of Mobile WMS solutions in India has revolutionized how delivery stations operate. By extending WMS capabilities to mobile devices, staff gain:

- Barcode/QR code scanning for rapid package verification

- Mobile access to delivery instructions and customer preferences

- Real-time communication with warehouse and customer service teams

- Digital proof of delivery and COD collection verification

- Access to historical delivery data for returning customers

These mobile solutions are particularly valuable in India, where smartphones are ubiquitous even when other technology infrastructure may be limited. Leading companies like Amazon India have deployed multilingual mobile WMS applications that function effectively even in areas with intermittent connectivity—a critical feature across India’s diverse geography.

AI and Machine Learning for Predictive Operations

AI in last mile delivery represents the cutting edge of WMS integration, with algorithms analyzing data across the entire fulfillment journey to:

- Predict delivery exceptions before they occur

- Optimize sorting workflows based on historical performance

- Identify potential bottlenecks during festival seasons

- Recommend staff allocation based on incoming volume patterns

- Improve delivery accuracy through address standardization and landmark identification

Myntra has leveraged these capabilities to achieve a 29% reduction in delivery exceptions during their End of Reason Sale events, when volumes spike dramatically across their network of delivery stations.

API Integration for Seamless Data Flow

Modern WMS-last mile integration relies heavily on API integration logistics to ensure real-time data exchange between systems. These APIs enable:

- Bidirectional communication between warehouse systems and delivery station platforms

- Integration with multiple delivery partners through standardized interfaces

- Real-time status updates visible to both operational teams and customers

- Automated exception handling and escalation

- Consistent data formats across diverse systems and partners

Companies like Omneelab have built their entire business model around API-based integration platforms that allow even small e-commerce players to achieve enterprise-grade connectivity between their WMS and last mile operations. Selecting the right WMS is crucial for last mile success. Here’s a guide on Choosing the Right Warehouse Management Solution.

Operational Benefits of WMS Integration at Delivery Stations

Enhanced Route Planning and Optimization

When WMS data flows seamlessly to delivery stations, it enables superior WMS and route optimization through:

- Package clustering based on geographical proximity

- Load balancing across available delivery personnel

- Dynamic route adjustments based on real-time conditions

- Prioritization of time-sensitive deliveries within routes

- Optimization for specific delivery vehicles (two-wheelers vs. vans)

Grofers (now Blinkit) implemented this integration and reduced their delivery miles by 24% while increasing on-time delivery performance by 27%—a win for both operational efficiency and customer satisfaction.

Improved Handling of Reverse Logistics

Reverse logistics management becomes dramatically more efficient when WMS is integrated with delivery stations. The benefits include:

- Streamlined return authorization and verification

- Quick reintroduction of saleable returned items into inventory

- Automated quality control workflows for returned goods

- Optimization of return pickup routes

- Data analytics to identify return patterns and reduce future returns

This is particularly crucial in India’s fashion e-commerce segment, where return rates can exceed 30%. Myntra’s integrated return process allows delivery personnel to verify and process returns at the customer’s doorstep, with real-time WMS updates ensuring fast refunds while efficiently routing returned items back to the appropriate facility.

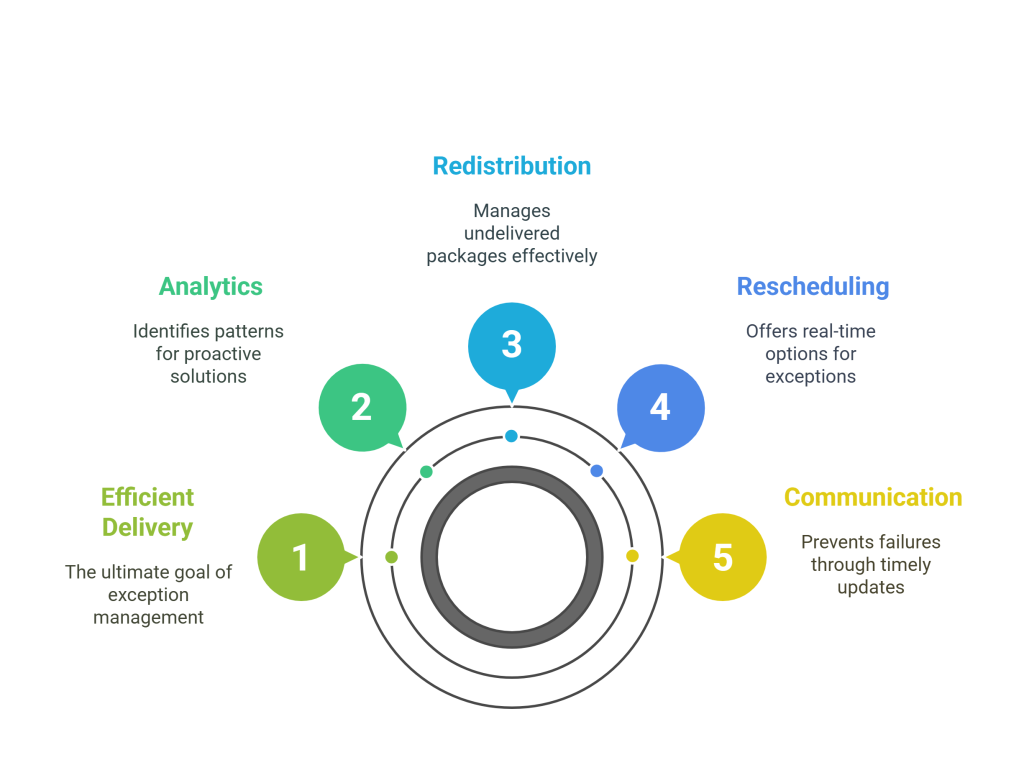

Delivery Exception Management and Resolution

Every delivery operation faces exceptions—the missed deliveries, address issues, or customer unavailability that disrupt standard processes. Integrated WMS systems enable superior delivery exception management through:

- Early identification of potential delivery issues

- Automated customer communication to prevent failed deliveries

- Real-time rescheduling options when exceptions occur

- Efficient redistribution of undelivered packages

- Analytics to identify recurring exception patterns

Zomato and Swiggy have implemented sophisticated exception management within their food delivery networks, resulting in a 35% reduction in failed deliveries and significantly improved customer satisfaction scores.

Addressing India’s Unique Last Mile Challenges

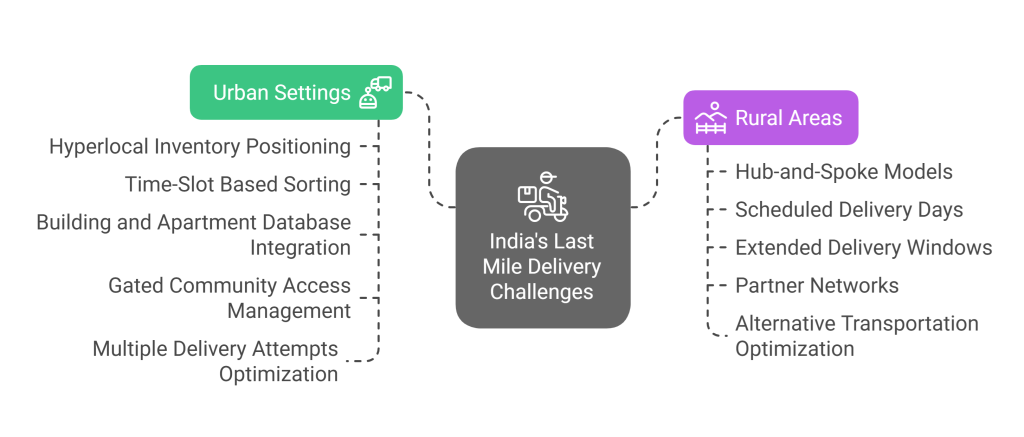

Urban vs. Rural Delivery Optimization

Rural and urban delivery challenges in India require fundamentally different approaches, which integrated WMS systems can address through:

Urban Settings:

- Hyperlocal inventory positioning to navigate congestion

- Time-slot based sorting to avoid peak traffic periods

- Building and apartment database integration

- Gated community access management

- Multiple delivery attempts optimization

Rural Areas:

- Hub-and-spoke models with village-level aggregation points

- Scheduled delivery days for remote locations

- Extended delivery windows with precise communication

- Partner networks including local kirana stores

- Alternative transportation optimization (motorcycles, bicycles)

Amazon India’s differentiated approach has allowed them to serve over 100% more pin codes than most competitors while maintaining consistent delivery performance across both urban and rural settings. Explore more about Technologies in Warehousing & Logistics in India that are shaping the future.

Festival Season and Peak Management

India’s festival seasons create dramatic demand spikes that put enormous pressure on delivery stations. Integrated WMS systems help manage these periods through:

- Advanced forecasting and resource allocation

- Temporary capacity expansion through pop-up delivery stations

- Prioritization frameworks for time-sensitive festival items

- Pre-staging of high-demand products at strategic locations

- Flexible workforce management integrated with WMS data

Festival season logistics in India benefit tremendously from this integration. Flipkart’s Big Billion Days sale saw a 42% improvement in on-time delivery performance after implementing their integrated WMS-last mile platform, despite handling record volumes.

Cash-on-Delivery Handling and Verification

Cash-on-delivery verification remains a critical challenge in India’s e-commerce ecosystem, with COD still accounting for approximately 60% of orders in many categories. Integrated WMS solutions address this through:

- Digital reconciliation of COD collections at delivery stations

- Real-time payment verification and order status updates

- Exception workflows for partial payments or denomination issues

- Fraud prevention through historical customer data

- Automated deposit and accounting integration

These improvements reduce the financial and operational friction associated with COD transactions, a particularly important consideration for delivery stations handling hundreds or thousands of such transactions daily.

Strategic Implementations Across India’s Logistics Landscape

Micro-Fulfillment Centers as Enhanced Delivery Stations

The rise of micro-fulfillment centers represents one of the most innovative applications of WMS in last mile delivery. These hybrid facilities combine warehouse capabilities with delivery station functionality, enabling:

- Hyperlocal inventory positioning for rapid delivery

- Dark store operations for efficient picking

- Integration with traditional retail for omnichannel fulfillment

- Flexible space utilization based on local demand patterns

- Reduced transportation costs and delivery times

Companies like Blinkit and Zepto have built their entire business models around this concept, achieving consistent delivery times under 20 minutes in major Indian metros by deploying sophisticated WMS capabilities within these micro-fulfillment centers.

Kirana Store Integration for Last Mile Excellence

India’s network of neighborhood kirana stores represents an unparalleled opportunity for last mile optimization. Advanced kirana store logistics integration through WMS includes:

- Inventory visibility across participating stores

- Order routing to the closest kirana partner

- Click-and-collect capabilities with real-time notifications

- Returns processing at convenient neighborhood locations

- Customer service touch points with local relationships

Reliance JioMart has leveraged this model extensively, integrating thousands of kirana partners into their delivery network through a simplified WMS interface that allows even technology-hesitant store owners to participate effectively in digital commerce.

Omnichannel Integration for Seamless Customer Experience

Omnichannel fulfillment in India requires sophisticated WMS integration at delivery stations to support diverse customer journeys:

- Buy online, pick up in-store (BOPIS) coordination

- Ship-from-store fulfillment management

- Endless aisle capabilities with cross-location visibility

- Consistent inventory across online and offline touchpoints

- Unified customer history and preference data

Retailers like Croma and Lifestyle have invested heavily in these capabilities, allowing their stores to double as micro-fulfillment centers and delivery stations while maintaining consistent customer experience across channels.

Measuring Success: KPIs for WMS-Optimized Delivery Stations

Effective measurement is essential for continuous improvement of integrated WMS and last mile operations. Key metrics include:

- Station processing time (from receipt to departure)

- Sort accuracy rates

- First-attempt delivery success percentage

- Perfect order rates (right item, right place, right time, right condition)

- Return processing efficiency

- Delivery time accuracy

- Exception rates and resolution times

- Cost per delivery by region and product type

Leading organizations establish dashboards that provide real-time visibility into these metrics, enabling proactive management and continuous improvement of their delivery station operations.

Future Trends in WMS and Last Mile Delivery Station Integration

Sustainable Last Mile Operations

Sustainable last mile operations are becoming increasingly important as environmental awareness grows among both businesses and consumers in India. WMS integration enables sustainability through:

- Optimized packaging based on actual product dimensions

- Reduced carbon footprint through route optimization

- Electric vehicle integration with charging infrastructure planning

- Consolidated deliveries to minimize trips

- Reusable packaging management and tracking

Companies like Flipkart with their electric vehicle fleet and BlueDart’s carbon-neutral delivery program demonstrate how WMS integration can support environmental goals while maintaining operational excellence.

Voice and Vernacular Integration

India’s linguistic diversity makes voice and vernacular capabilities particularly valuable in delivery station operations. Advanced implementations now include:

- Voice-directed sorting in regional languages

- Multilingual mobile applications for delivery personnel

- Customer communications in preferred regional languages

- Voice authentication for delivery verification

- Natural language processing for address disambiguation

These capabilities help overcome literacy barriers and improve efficiency, particularly important as e-commerce expands into tier-3 and tier-4 markets across India.

IoT and Connected Delivery Ecosystems

The Internet of Things (IoT) is extending WMS capabilities into a fully connected delivery ecosystem through:

- Smart packaging with embedded tracking

- Environmental monitoring for sensitive products

- Connected vehicles with real-time location and status

- Smart delivery lockers integrated with WMS

- Automated notification triggers based on physical events

These technologies create unprecedented visibility and control across the entire fulfillment journey, from warehouse to delivery station to final customer handoff.

Conclusion

As India’s e-commerce landscape continues to evolve, the integration of WMS for last mile delivery has emerged as a critical competitive advantage. This integration transforms delivery stations from potential bottlenecks into strategic assets that enhance both operational efficiency and customer satisfaction.

The companies that will lead India’s e-commerce future are those that recognize delivery stations not simply as transfer points, but as sophisticated nodes in an integrated supply chain—nodes that require the same level of system support and optimization traditionally reserved for warehouses.

By implementing integrated WMS capabilities at delivery stations, organizations can achieve the visibility, efficiency, and adaptability needed to meet ever-rising customer expectations while managing costs across India’s complex and diverse landscape. The question is no longer whether to integrate WMS with last mile delivery stations, but how quickly and effectively you can implement this essential transformation.

Whether serving dense urban apartments in Bangalore or remote villages in Himachal Pradesh, the future of last mile delivery in India belongs to those who recognize that excellence begins not at the doorstep, but at the seamless integration of systems across the entire fulfillment journey.

Frequently Asked Questions

WMS integration improves inventory accuracy through barcode/QR code verification at transfer points, real-time synchronization between warehouse and delivery station systems, automated exception alerts, cycle counting functionality, and digital proof of receipt. Companies implementing integrated WMS solutions typically see inventory accuracy improvements of 15-25% at their delivery stations, directly reducing misplaced packages and improving delivery time accuracy.

AI transforms delivery station operations through predictive volume forecasting, intelligent labor allocation, dynamic route optimization, automated address correction for India’s complex addressing system, anomaly detection for potential delays, and continuous learning from delivery outcomes. These capabilities are particularly valuable during festival season logistics in India when volumes spike dramatically and predictive insights become crucial for maintaining service levels.

Small businesses can leverage cloud-based WMS solutions with pre-built integrations to popular courier services, utilize third-party logistics (3PL) providers with integrated systems, implement mobile-first solutions with minimal infrastructure requirements, adopt pay-as-you-go models that scale with business growth, and focus on API integration logistics that allows them to connect with established delivery networks without significant investment. Platforms like Shiprocket and Omneelab integrated solutions have democratized access to sophisticated WMS-last mile capabilities.

Successful implementation requires focusing on hyperlocal inventory management, real-time synchronization with central systems, space-efficient storage solutions, pick path optimization for small footprints, integrated delivery dispatch capabilities, returns processing workflows, and flexible resource allocation. Micro-fulfillment centers require WMS solutions that combine warehouse and delivery station functionality in a compact, efficient package optimized for rapid throughput rather than long-term storage.

WMS contributes to sustainable last mile operations by optimizing delivery routes to reduce fuel consumption, enabling consolidated deliveries to minimize trips, supporting electric vehicle adoption with charging scheduling, implementing right-sized packaging algorithms, facilitating reusable packaging programs with tracking capabilities, and providing analytics to measure and continuously improve environmental impact. These capabilities help companies meet increasing consumer demand for environmentally responsible delivery options while also reducing operational costs.

People also read:

- WMS for BigCommerce

- Demand-driven Replenishment Practices for Retailers

- Guide to Managing Perishable Inventory

- What Is a Bill of Materials (BOM)? Expert Guide & Tips

- Inventory Management with Barcode Technology

- Common Inventory Management Challenges

- Comprehensive Guide to Inventory Management Systems

- Manual and Automated Inventory Management

- Top 10 Tips for Warehouse Management Software

- Small Business Barcoding

Kapil Pathak is a Senior Digital Marketing Executive with over four years of experience specializing in the logistics and supply chain industry. His expertise spans digital strategy, search engine optimization (SEO), search engine marketing (SEM), and multi-channel campaign management. He has a proven track record of developing initiatives that increase brand visibility, generate qualified leads, and drive growth for D2C & B2B technology companies.