Running a successful business on Tata CLiQ while managing inventory across multiple warehouses can feel like managing a cricket team where half your players are in Mumbai, some in Delhi, and others in Bangalore – all trying to play the same match! One miscommunication, and your entire game plan falls apart. But here’s the good news – with the right wms for tata cliq multi-warehouse strategy, you can transform this chaotic situation into a well-coordinated team effort.

If you’ve ever found yourself scrambling during festive seasons like Diwali or Dussehra sales, checking stock levels across different godowns, wondering why your tata cliq stock accuracy wms isn’t showing real-time data, or dealing with angry customers because of out-of-stock situations, you’re definitely not alone. These challenges are exactly why smart Indian sellers are turning to sophisticated warehouse management systems designed specifically for our marketplace ecosystem.

According to recent industry data, sellers using integrated WMS solutions report 40% fewer stockouts and 35% improvement in order fulfillment accuracy during peak seasons.

Understanding Multi-Warehouse Challenges for Indian Sellers

Managing a tata cliq warehouse management system across multiple locations in India isn’t just about having inventory scattered from Chennai to Chandigarh. It’s about creating a seamless network where each warehouse – whether it’s your main facility in Gurgaon or your smaller distribution center in Pune – works together like a well-oiled machine.

Think of it like running multiple kiranas (local stores) under one brand. You wouldn’t want your South Delhi store running out of popular items while your Noida branch has excess stock gathering dust. The same logic applies to your multi location inventory tata cliq strategy.

Common Headaches Indian Sellers Face

Most Tata CLiQ sellers across India struggle with several interconnected problems:

- Poor visibility of stock across different warehouse locations

- Manual inventory updates that lead to overselling during peak seasons like Big Billion Days

- Inefficient order routing that increases courier costs significantly

- Delayed stock updates between warehouses and Tata CLiQ platform

- Inaccurate demand planning for regional preferences and festivals

These issues don’t just hurt your profit margins – they directly impact your seller ratings and customer trust, which is absolutely crucial in the competitive Indian e-commerce landscape.

Ready to eliminate these challenges? Book a free Consultation with our expert solution team

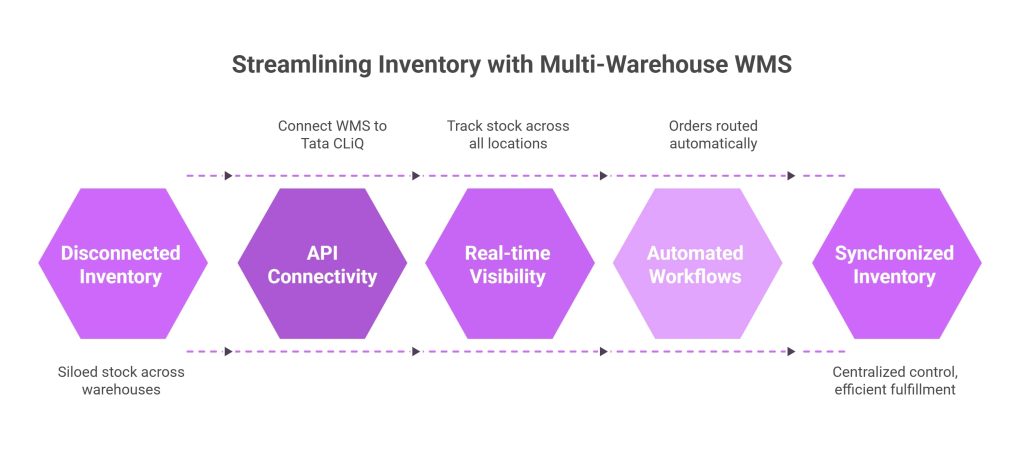

How Multi-Warehouse WMS Works with Tata CLiQ

A robust tata cliq seller inventory sync system works like the control room of Indian Railways – coordinating multiple moving parts to ensure everything runs smoothly. It connects all your physical locations with Tata CLiQ’s marketplace platform, creating real-time visibility and automated workflows that actually work in Indian conditions.

The integration functions through API connectivity that allows your WMS to communicate directly with Tata CLiQ’s seller portal. This means when a customer from Hyderabad places an order during a midnight sale, the system automatically:

- Checks stock availability across all your connected warehouses

- Routes the order to the closest fulfillment location (maybe your Chennai facility)

- Updates inventory levels instantly across all channels

- Sends replenishment alerts when stock hits minimum levels

Real-Time Inventory Tracking for Indian Markets

With proper warehouse automation tata cliq marketplace integration, you get crystal-clear visibility into your inventory movements. The system tracks every saree, smartphone, or kitchen appliance from the moment it enters your Bhiwandi warehouse until it reaches a customer’s home in Kochi.

This real-time inventory tracking eliminates the guesswork that often leads to expensive mistakes during high-volume sale periods. You’ll know exactly how much stock you have, where it’s located, and when you need to reorder – all without making endless phone calls to different warehouse managers.

Essential Features for Indian Tata CLiQ Operations

When evaluating a tata cliq fulfillment center management solution for Indian operations, certain features are absolutely essential.

Smart Order Routing for Indian Geography

Your WMS should include intelligent order routing algorithms that understand the unique challenges of Indian logistics:

- Pin code-wise delivery optimization considering local courier capabilities

- Regional festival demand patterns (like higher electronics sales during Diwali in North India)

- Monsoon season logistics planning for affected regions

- Tier-2 and Tier-3 city delivery considerations

- Cash-on-delivery preference handling across different regions

Stock Level Synchronization Across Time Zones

Effective stock level synchronization ensures your inventory data stays accurate whether you’re managing warehouses in Kolkata’s morning rush or Mumbai’s late-night operations. This means your Tata CLiQ listings always show correct availability, preventing the nightmare of selling products you don’t have during peak shopping hours.

The system should update inventory levels within seconds, whether it’s a sale during lunch break, a return during evening hours, or internal stock movement during night shifts.

Comprehensive Inventory Dashboard

A well-designed inventory visibility dashboard gives you a complete view of your pan-India operations. You can monitor stock levels from Kashmir to Kanyakumari, track order fulfillment progress, and spot potential issues before they affect your customer ratings.

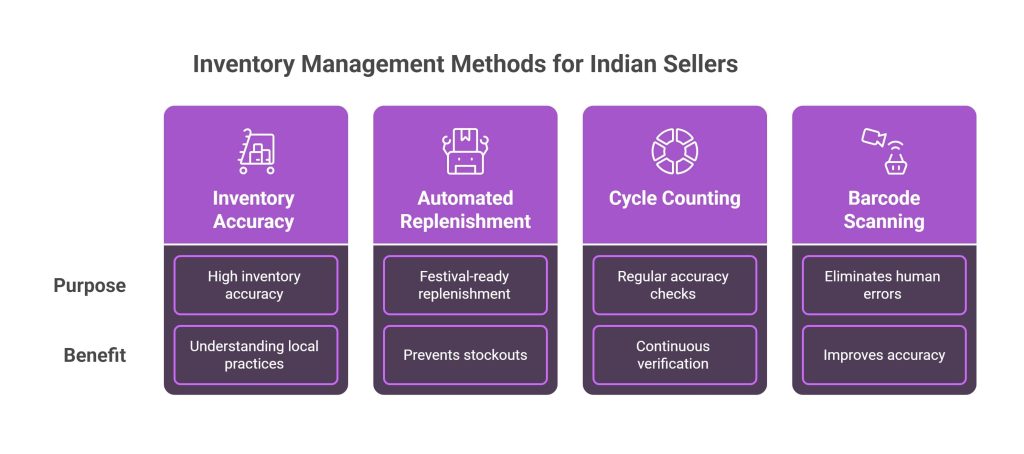

Implementing Stock Accuracy for Indian Sellers

Achieving high inventory accuracy tata cliq integration in India requires understanding local business practices and seasonal patterns.

Festival-Ready Automated Replenishment

Smart automated replenishment systems understand Indian buying patterns – from Raksha Bandhan gift rushes to wedding season jewelry demands. The system analyzes historical sales data, regional festivals, and current inventory levels to automatically generate purchase orders when stock levels drop below optimal thresholds.

This proactive approach prevents stockouts during crucial selling periods while avoiding the cash flow issues that come with overstocking slow-moving items.

Accurate Cycle Counting Methods

Regular cycle counting accuracy checks ensure your physical inventory matches your system records – crucial when dealing with high-value items like electronics or gold jewelry. Instead of shutting down operations for annual physical counts (which can be expensive in India), modern WMS solutions enable continuous verification through systematic sampling.

The system can prioritize high-value items or fast-moving products for more frequent counts, ensuring your most critical inventory data remains accurate during busy periods.

Barcode Integration for Indian Warehouses

Implementing barcode scanning systems eliminates human errors common in manual inventory processes. Every receipt, movement, and shipment gets tracked automatically, creating an audit trail that improves accuracy and helps with GST compliance.

Pro Tip: Sellers using barcode integration report 89% reduction in picking errors and 45% faster order processing times.

Strategic Warehouse Distribution Across India

Your tata cliq multi-warehouse setup should be designed around Indian customer behavior patterns and regional logistics capabilities rather than just following major city locations.

Regional Demand Forecasting

Advanced demand forecasting capabilities analyze Indian market patterns – like increased AC sales before summer in South India or higher woolen wear demand in North India during winter. This intelligence drives smarter inventory allocation decisions across your warehouse network.

For instance, if data shows that certain fashion items sell better in metro cities while traditional items perform well in smaller towns, the system automatically adjusts stock distribution accordingly.

Safety Stock for Indian Market Volatility

Proper safety stock calculations in India must account for factors like monsoon delays, festival season spikes, and supplier reliability issues. The system considers local factors like transportation strikes, regional holidays, and seasonal demand variations to determine optimal safety stock levels for each warehouse.

Location-Based Allocation Rules

Configurable warehouse allocation rules ensure inventory gets distributed according to Indian market realities. You might prioritize electronics for your Bangalore warehouse (tech hub demand) while allocating traditional wear to your Jaipur facility (cultural preference).

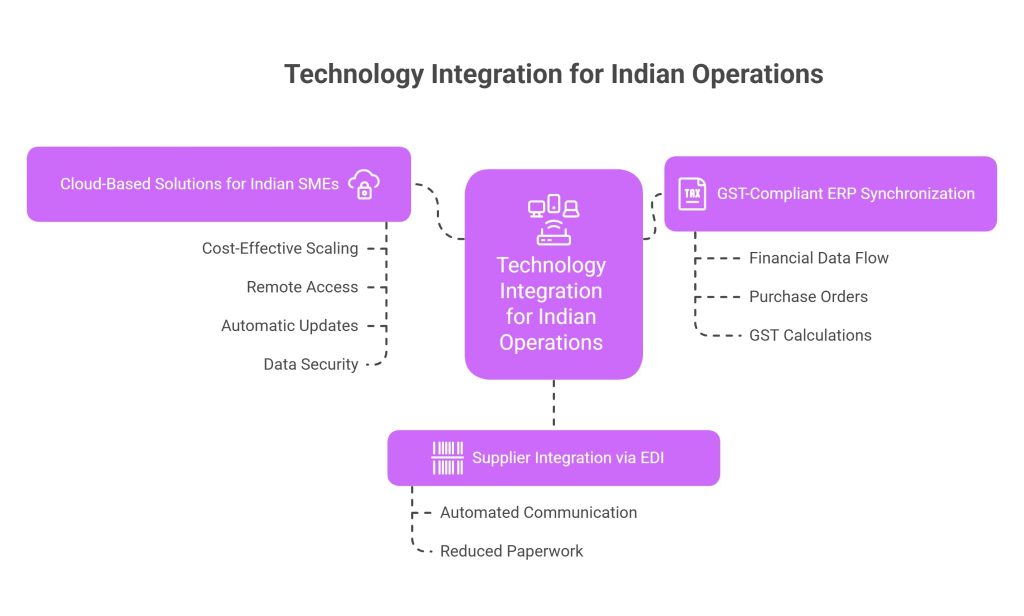

Technology Integration for Indian Operations

Modern tata cliq inventory management software must integrate seamlessly with Indian business systems and compliance requirements.

GST-Compliant ERP Synchronization

ERP synchronization ensures your warehouse management system works with Indian accounting and GST compliance systems. Financial data, purchase orders, and GST calculations flow seamlessly between systems, eliminating duplicate data entry and ensuring compliance with Indian tax regulations.

Supplier Integration via EDI

EDI integration capabilities enable automated communication with Indian suppliers and logistics partners. Purchase orders, advance shipping notices, and invoices can be exchanged electronically, speeding up processes that traditionally involved multiple phone calls and manual paperwork.

Cloud-Based Solutions for Indian SMEs

A cloud-based WMS offers particular advantages for Indian businesses:

- Cost-effective scaling without heavy infrastructure investments

- Remote access from anywhere with internet (crucial for multi-city operations)

- Automatic updates without IT team dependency

- Lower operational costs compared to server maintenance

- Built-in data security and backup systems

Solutions like Omni-WMS are specifically designed to handle the complexities of Indian multi-warehouse operations, offering seamless integration with local business practices and compliance requirements while maintaining the flexibility to scale across diverse market conditions.

Optimizing Operations for Indian Logistics

Efficient pick-pack-ship workflows must account for Indian logistics realities and customer expectations.

Peak Season Wave Planning

Smart wave planning becomes crucial during Indian sale seasons like Big Billion Days, Diwali sales, or end-of-season clearances. The system groups orders for optimal picking efficiency while considering factors like regional courier cutoff times and cash-on-delivery processing requirements.

Quality Control for Indian Markets

Strategic quality control checkpoints are essential when dealing with diverse product categories and customer expectations. This includes verifying product authenticity (crucial for electronics and branded items), checking packaging quality for long-distance shipping, and confirming accurate invoicing for GST compliance.

Efficient Returns Processing

Streamlined returns processing handles the high return rates common in Indian e-commerce, especially for fashion and electronics. The system routes returned items to appropriate locations for quality checks, refurbishment, or disposal while maintaining proper documentation for tax purposes.

Industry Insight: Efficient returns processing can reduce RTO (Return to Origin) rates by up to 25% and improve customer satisfaction scores.

Performance Analytics for Indian Markets

Your warehouse optimization tata cliq platform should provide insights specific to Indian market dynamics.

India-Specific KPIs

Monitor metrics that matter for Indian operations:

- Regional fulfillment accuracy across different states

- Festival season performance compared to regular periods

- COD vs. prepaid order efficiency ratios

- Tier-2/Tier-3 city delivery success rates

- Customer satisfaction scores by region and product category

Market Intelligence Integration

A comprehensive data analytics platform should incorporate Indian market intelligence – understanding regional preferences, seasonal patterns, and competitive dynamics to drive better business decisions.

Companies like Omneelab Technologies have developed sophisticated analytics capabilities that help Indian sellers make data-driven decisions by analyzing marketplace trends, customer behavior patterns, and operational efficiency metrics specific to the Indian e-commerce ecosystem.

Scaling Operations Across India

As your business expands from metros to smaller cities, your WMS should adapt to Indian market realities.

Multi-City Expansion Support

Choose a system that can handle the complexity of expanding across Indian markets – from understanding local regulations to managing different logistics partners in various states.

Regional Customization Capabilities

Your WMS should support regional customizations – different languages for warehouse staff, local holiday calendars, and region-specific business practices.

Integration with Indian Logistics Ecosystem

Look for systems that integrate well with popular Indian logistics providers, payment gateways, and marketplace platforms beyond just Tata CLiQ. Advanced Last Mile SaaS solutions can significantly improve delivery performance by optimizing route planning, providing real-time tracking, and managing customer communication throughout the delivery process, which is crucial for maintaining high seller ratings on marketplaces like Tata CLiQ.

Conclusion

Implementing an effective wms for tata cliq multi-warehouse strategy in India isn’t just about managing inventory – it’s about understanding and adapting to the unique challenges and opportunities of the Indian market. The right system transforms complex multi-location operations into a competitive advantage that helps you serve customers better while building a profitable business.

Success in the Indian e-commerce landscape comes from choosing a solution that addresses current challenges while positioning your business for expansion across the diverse Indian market. With proper tata cliq stock accuracy wms implementation, you’ll eliminate inventory management stress while building a foundation for sustainable growth from metros to tier-3 cities.

Ready to transform your multi-warehouse operations for the Indian market? Explore how Omneelab’s India-focused WMS solutions can optimize your Tata CLiQ seller performance and help you capture opportunities across the entire Indian marketplace.

Frequently Asked Questions

Implementation typically takes 6-10 weeks for Indian operations, considering factors like GST integration, regional customizations, and staff training across different locations. The timeline includes system configuration, API setup with Tata CLiQ, training warehouse staff (often in local languages), and thorough testing during low-volume periods. Most Indian businesses see improvements within the first month, especially during festival seasons.

Absolutely! Modern WMS solutions are designed to understand Indian market dynamics. They can manage region-specific inventory allocation (like more traditional wear in Rajasthan, tech products in Bangalore), seasonal demands (ACs before summer, woolen wear before winter), and festival-driven sales patterns. The system automatically adjusts stock distribution based on historical data and regional trends.

The WMS integrates with Indian payment systems and GST requirements seamlessly. For COD orders, it tracks payment collection status and manages reconciliation with logistics partners. For GST compliance, it maintains proper documentation, generates required invoices, and integrates with accounting systems to ensure accurate tax calculations and filing.

The system includes contingency planning features that automatically reroute orders to alternative warehouses or logistics partners during disruptions. It maintains buffer stock calculations considering Indian logistics challenges and can switch fulfillment strategies based on real-time conditions. The system also provides proactive alerts to customers about potential delays.

Yes, modern WMS solutions are designed for growing Indian SMEs with user-friendly interfaces and scalable features. Cloud-based systems offer easy deployment, automatic updates, and the flexibility to start small and expand as your business grows. Most Indian businesses see significant improvements in operational efficiency and customer satisfaction within 6-8 months, helping smaller sellers compete effectively with larger players on Tata CLiQ.

People also read:

- WMS for Snapdeal

- WMS for Nykaa

- JioMart WMS Integration

- Inventory Management with Barcode Technology

- Common Inventory Management Challenges

- WMS for Magento

- WMS for WooCommerce

- WMS for Last Mile in India

- Small Business Barcoding

- What Is a Bill of Materials (BOM)? Expert Guide & Tips

Kapil Pathak is a Senior Digital Marketing Executive with over four years of experience specializing in the logistics and supply chain industry. His expertise spans digital strategy, search engine optimization (SEO), search engine marketing (SEM), and multi-channel campaign management. He has a proven track record of developing initiatives that increase brand visibility, generate qualified leads, and drive growth for D2C & B2B technology companies.