Ever wondered how Snapdeal bounced back from near-collapse to become one of India’s most efficient e-commerce platforms? The secret sauce wasn’t just smart business decisions—it was revolutionary warehouse management that turned chaos into clockwork precision.

Picture this: you’re managing 500,000+ retailers, serving 4 crore customers, and somehow you need to cut losses by 95% while growing revenue by 74%. Sounds impossible? Not when you have the right warehouse management system powering your operations behind the scenes.

If you’re running an e-commerce business or dreaming of Snapdeal-level success, buckle up. We’re about to dive deep into the world of WMS for Snapdeal and show you exactly how to implement these game-changing systems for your own e-commerce empire.

Why Every E-commerce Business Needs to Think Like Snapdeal

Let’s be honest—running an e-commerce business without proper warehouse management system Snapdeal-style operations is like trying to conduct an orchestra while blindfolded. You might hit a few right notes, but you’ll never create a symphony.

Snapdeal’s transformation didn’t happen overnight. It required a complete overhaul of their e-commerce fulfillment solutions, turning their warehouses from cost centers into profit engines. Here’s what makes their approach so brilliant:

The Scale Reality Check When you’re processing thousands of orders daily across multiple product categories, every second counts. Without sophisticated e-commerce warehouse automation, even tiny inefficiencies snowball into massive problems. Think about it—if each order takes just 30 seconds longer to process, and you’re handling 10,000 orders daily, that’s 83 extra hours of labor every single day!

Customer Expectations Have Gone Crazy Today’s customers don’t just want fast delivery—they expect it. Same-day shipping, real-time tracking, hassle-free returns. Meeting these expectations requires warehouse operations management systems that work like Swiss watches, not rusty alarm clocks.

Omneelab Suite: Your Complete E-commerce Transformation Partner

Ready to revolutionize your e-commerce operations like Snapdeal? Omneelab Suite offers integrated solutions that transform your entire business ecosystem. From inventory management to customer analytics, our comprehensive platform helps you scale efficiently while maintaining operational excellence. Join 100+ successful e-commerce businesses already using Omneelab Suite to drive growth.

The Anatomy of a Snapdeal-Level WMS Implementation

Understanding What Makes WMS Tick

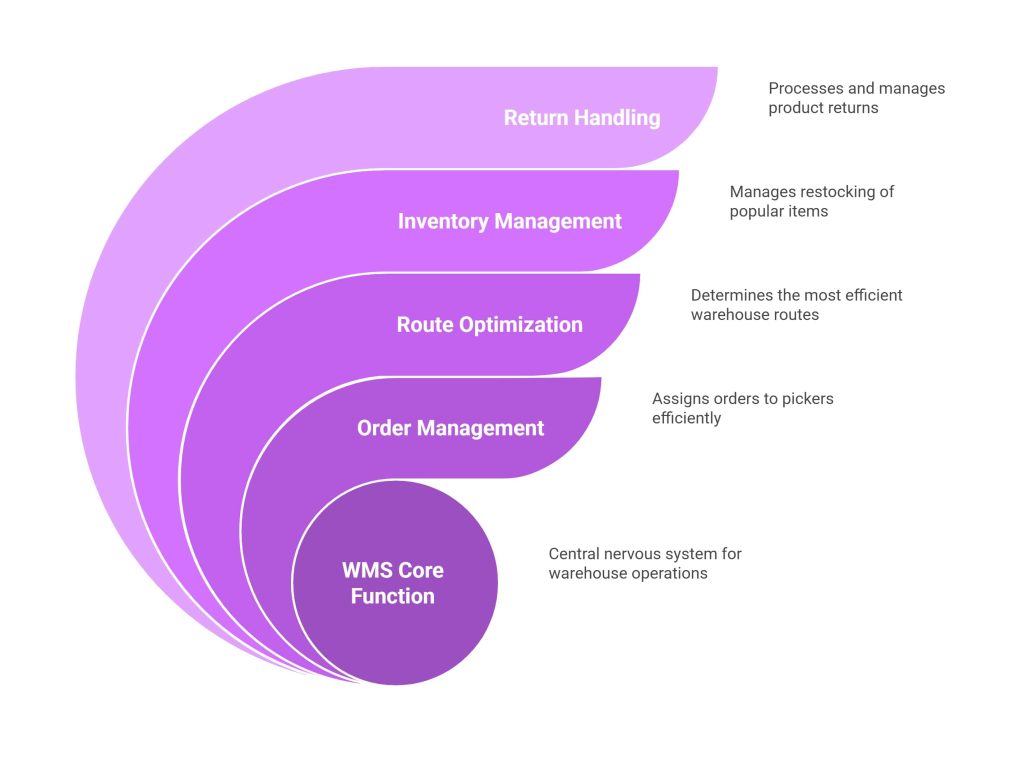

Before we dive into the nitty-gritty of Snapdeal WMS implementation, let’s understand what we’re actually building here. A modern warehouse management system for e-commerce isn’t just software—it’s the nervous system of your entire operation.

Think of it as your warehouse’s brain, constantly making thousands of micro-decisions:

- Which picker should handle which order?

- What’s the most efficient route through the warehouse?

- When should we restock that popular item?

- How do we handle that tricky return?

Core Components That Matter

- Real-time Stock Tracking: Imagine knowing exactly where every single item is, every second of the day. No more “we think it’s in aisle 7” situations.

- Multi-channel Inventory Control: Whether someone buys from your website, mobile app, or third-party marketplace, your system knows instantly and adjusts everywhere else.

- Order Fulfillment Automation: From the moment someone clicks “buy” to when they receive their package, every step is orchestrated automatically.

The Features That Separate Winners from Wannabes

When we talk about Indian e-commerce WMS solutions, certain features become absolutely non-negotiable. Let me share what separates the champions from the also-rans:

Smart Inventory Management Systems Modern inventory management systems are like having a crystal ball for your stock. They don’t just tell you what you have—they predict what you’ll need, when you’ll need it, and how much it’ll cost to get there.

- ABC Analysis Integration: Your system automatically identifies which products are your goldmines (A items), steady performers (B items), and slow movers (C items)

- Predictive Restocking: Using AI algorithms, the system forecasts demand and triggers reorders before you run out

- Seasonal Adjustment: Smart systems learn your business patterns and adjust for festivals, sales events, and seasonal trends

Next-Level Automation Capabilities

Barcode Scanning Systems: These aren’t your grandfather’s barcode scanners. Modern systems can read damaged codes, work in poor lighting, and even scan multiple items simultaneously.

RFID Warehouse Tracking: For high-value items or complex scenarios, RFID technology provides superhuman tracking capabilities. Imagine being able to locate any item in a 100,000 sq ft warehouse in under 30 seconds.

Pick, Pack, Ship Automation: The holy grail of e-commerce warehouse automation. Your system optimizes picking routes, suggests packing materials, and even prints shipping labels—all automatically.

Omni-WMS: Warehouse Management Perfected

Transform your warehouse into a precision-engineered fulfillment machine with Omni-WMS. Our intelligent warehouse management system offers real-time inventory tracking, automated order processing, and seamless integration with your existing e-commerce platforms. Experience 40% faster order processing and 99.8% inventory accuracy.

Your Step-by-Step Roadmap to WMS Success

Alright, let’s get practical. Here’s your complete WMS implementation guide that takes you from “where do we even start?” to “wow, this actually works!”

Phase 1: The Foundation Phase (Weeks 1-4)

Current State Reality Check Before you can build something amazing, you need to understand what you’re working with. This isn’t just about counting boxes—it’s about understanding your entire operation’s DNA.

What to Document:

- How long does it currently take to process an order from receipt to shipment?

- What’s your picking accuracy rate? (Be honest—if you don’t know, it’s probably worse than you think)

- How much time do your staff spend looking for items?

- What are your peak volume periods, and how do you currently handle them?

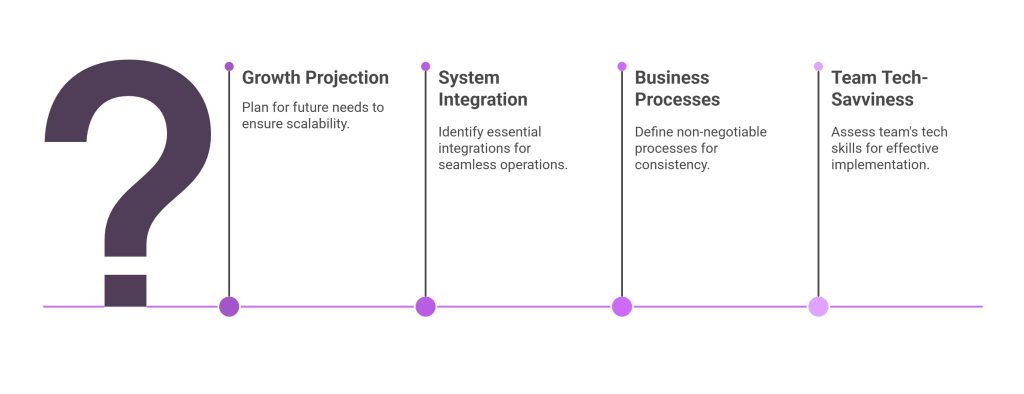

The Requirements Deep Dive This is where most implementations go wrong. Companies rush through requirements gathering and pay for it later with expensive customizations and frustrated users.

Critical Questions to Answer:

- What’s your 3-year growth projection? (Don’t just think about today’s needs)

- Which systems absolutely must integrate with your WMS?

- What are your non-negotiable business processes?

- How tech-savvy is your warehouse team?

Vendor Selection Strategy Here’s where WMS vendor comparison for online retail becomes crucial. Don’t just look at features—look at partnerships.

Evaluation Criteria That Actually Matter:

- E-commerce Experience: Have they implemented systems for businesses like yours?

- Scalability Proof: Can they show you clients who’ve grown 10x on their platform?

- Integration Flexibility: How easily do they connect with your existing tech stack?

- Support Philosophy: Do they just fix problems, or do they help you optimize?

Phase 2: Design and Build (Weeks 5-12)

System Architecture That Scales This is where you decide whether you’re building a bicycle or a Ferrari. The choice between cloud-based WMS for Snapdeal e-commerce versus on-premise solutions will impact your business for years.

Cloud vs. On-Premise Reality Check:

- Cloud Advantages: Faster deployment, automatic updates, lower upfront costs, built-in scalability

- On-Premise Advantages: Complete control, customization flexibility, no ongoing subscription costs

- Hybrid Approach: Best of both worlds, but more complex to manage

Process Mapping That Makes Sense Don’t just digitize your current processes—optimize them. This is your chance to eliminate those “we’ve always done it this way” inefficiencies.

Key Process Areas to Optimize:

- Receiving Workflows: How quickly can you get incoming inventory into sellable status?

- Put-Away Strategies: Are you storing items where they’ll be easiest to pick?

- Pick Path Optimization: Can you reduce walking time by 50%?

- Packing Procedures: Are you using the right box sizes and packing materials?

Phase 3: Testing and Training (Weeks 13-16)

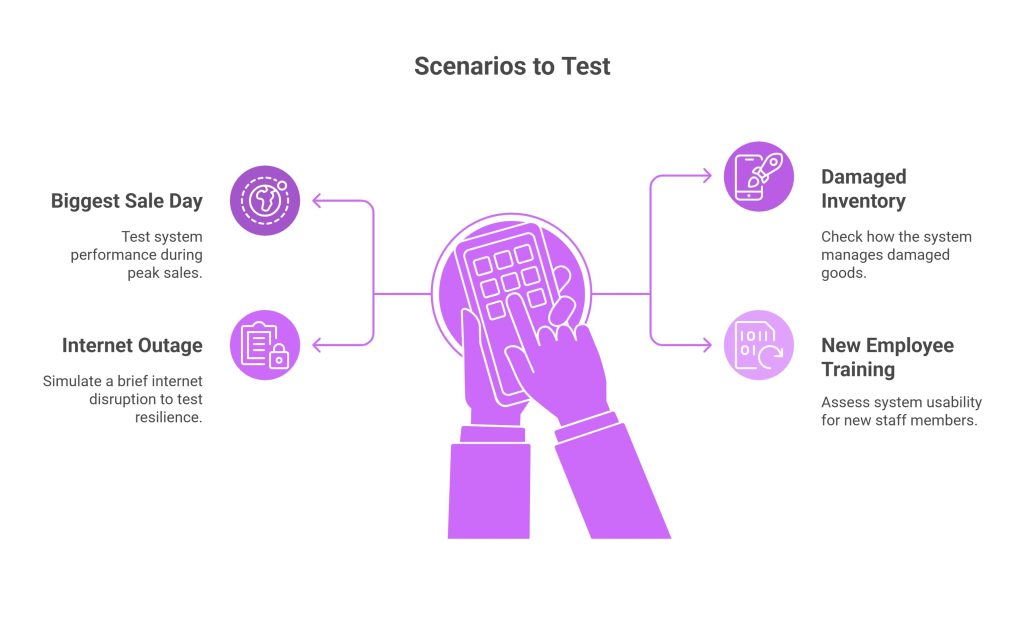

Testing That Actually Tests Most companies do “happy path” testing—everything works perfectly with perfect data. Real-world testing is messier and more valuable.

Scenarios to Test:

- What happens during your biggest sale day of the year?

- How does the system handle damaged inventory?

- What if your internet goes down for 30 minutes?

- Can new employees figure out the system without extensive training?

Training That Sticks The best WMS in the world is useless if your team can’t or won’t use it effectively.

Training Strategy That Works:

- Champions Program: Identify enthusiastic early adopters and make them internal experts

- Hands-On Practice: Use real data and real scenarios, not theoretical examples

- Ongoing Support: Training doesn’t end on go-live day

Phase 4: Go-Live and Optimization (Weeks 17-20)

The Soft Launch Approach Don’t try to boil the ocean on day one. Smart implementations start small and scale up.

Phased Rollout Strategy:

- Week 1: Single product category or warehouse section

- Week 2: Expand to 50% of operations

- Week 3: Full operations with close monitoring

- Week 4: Optimization based on real-world data

Last Mile BYOC Platform: Your Courier Network, Supercharged

Transform your existing courier partnerships into a precision delivery machine with our BYOC (Bring Your Own Courier) Platform. Seamlessly manage multiple courier partners, optimize route assignments, and maintain complete visibility across your entire delivery network. Achieve 99.5% on-time delivery rates while reducing logistics costs by 25% through intelligent courier selection and real-time performance tracking.

Common Pitfalls and How Smart Companies Avoid Them

The Integration Nightmare

The Problem: “Our WMS doesn’t talk to our e-commerce platform properly.”

The Solution: Plan integration from day one, not as an afterthought. Choose WMS providers with proven WMS integration with e-commerce platforms experience.

Pro Tips:

- Demand to see working integrations with your specific platform

- Plan for API rate limits and data synchronization delays

- Test integration thoroughly with peak-volume scenarios

The Change Management Disaster

The Problem: “Our staff hates the new system and productivity has actually decreased.”

The Solution: Invest heavily in change management from the beginning.

What Actually Works:

- Involve key users in system selection and configuration

- Create internal champions who become peer trainers

- Celebrate early wins and share success stories

- Provide ongoing support, not just initial training

The Data Migration Catastrophe

The Problem: “We lost 6 months of inventory data during migration.”

The Solution: Treat data migration like surgery—plan meticulously and have backup plans.

Migration Best Practices:

- Conduct multiple test migrations with real data

- Plan for data cleanup before migration

- Run parallel systems during transition period

- Have rollback procedures ready

Future-Proofing Your WMS Investment

AI and Machine Learning Integration

The future of supply chain optimization is already here, and it’s powered by artificial intelligence.

Current AI Applications:

- Demand Forecasting: Predict inventory needs with 95%+ accuracy

- Dynamic Slotting: Automatically optimize product placement based on picking patterns

- Route Optimization: Reduce picking time by up to 40% with AI-powered path planning

- Predictive Maintenance: Prevent equipment failures before they happen

IoT and Sensor Revolution

Internet of Things Integration:

- Environmental Monitoring: Automatic alerts for temperature, humidity, and other conditions

- Asset Tracking: Know the location and status of every piece of equipment

- Automated Counting: RFID and sensor-based inventory counting without human intervention

Robotics and Advanced Automation

Next-Generation Automation:

- Collaborative Robots (Cobots): Work alongside human pickers to increase efficiency

- Autonomous Mobile Robots (AMRs): Transport goods throughout the warehouse automatically

- Automated Storage and Retrieval Systems (AS/RS): Maximize storage density and picking speed

Measuring Success: KPIs That Actually Matter

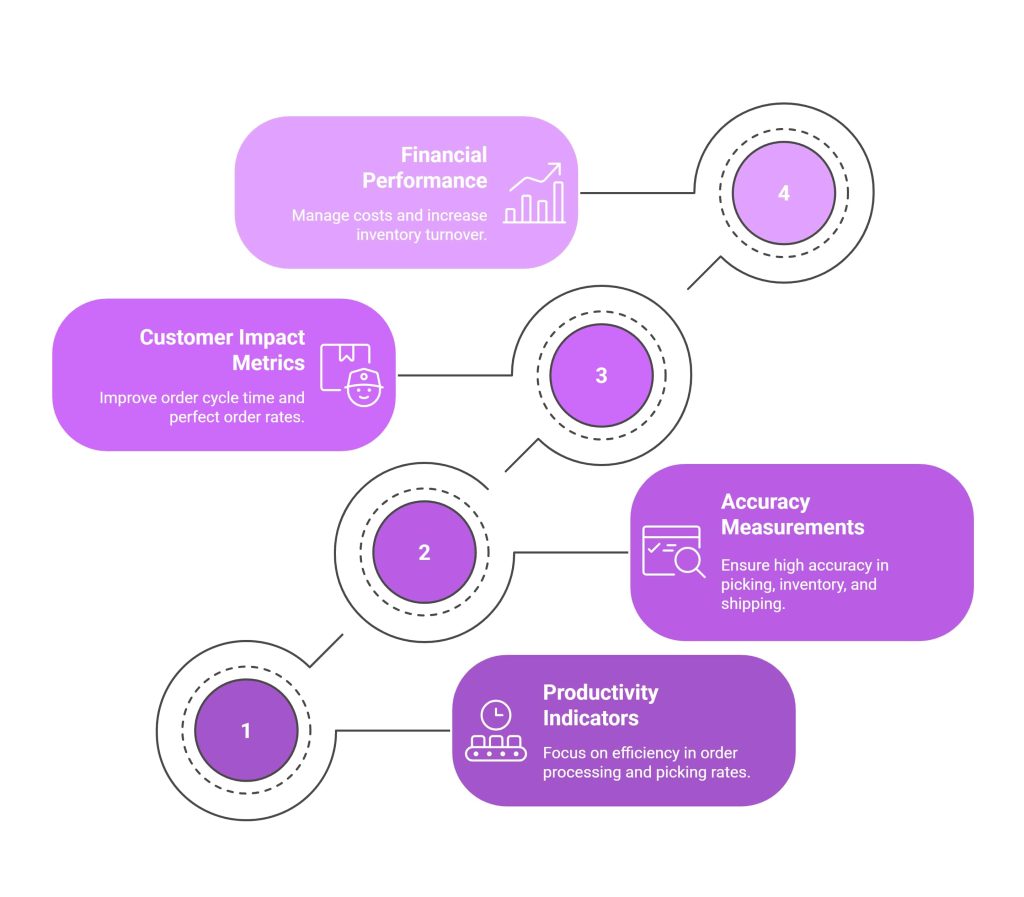

Operational Excellence Metrics

Productivity Indicators:

- Orders per Hour: Benchmark: 20-30 orders/hour for manual picking, 50+ for automated systems

- Pick Rate: Benchmark: 100-150 lines per hour for experienced pickers

- Dock-to-Stock Time: How quickly can you get received inventory into sellable status?

Accuracy Measurements:

- Picking Accuracy: Target: 99.5%+ (anything less impacts customer satisfaction)

- Inventory Accuracy: Target: 99%+ (critical for preventing stockouts and overstocks)

- Shipping Accuracy: Target: 99.8%+ (mistakes here are expensive to fix)

Customer Impact Metrics

Fulfillment Performance:

- Order Cycle Time: From order receipt to shipment

- Perfect Order Rate: Orders shipped complete, on-time, and damage-free

- Return Processing Time: How quickly can you process and restock returns?

Financial Performance Indicators

Cost Management:

- Cost per Order: Total warehouse costs divided by orders processed

- Labor Cost Percentage: Labor costs as a percentage of revenue

- Inventory Turnover: How quickly you’re converting inventory to sales

Best Practices from Snapdeal-Level Success Stories

Data-Driven Decision Making

Successful Snapdeal warehouse management best practices all center around using data to drive continuous improvement.

Analytics That Drive Action:

- Heat Mapping: Understand traffic patterns in your warehouse

- Performance Trending: Identify improving or declining trends before they become problems

- Exception Reporting: Focus management attention on outliers and anomalies

Continuous Optimization Culture

Monthly Optimization Reviews:

- Analyze picking route efficiency

- Review slotting decisions based on actual pick data

- Assess staffing levels against productivity metrics

- Identify training needs and opportunities

Seasonal Preparation:

- Plan capacity increases for peak seasons

- Optimize inventory positioning for expected demand patterns

- Cross-train staff for flexibility during high-volume periods

Your Action Plan: From Reading to Results

Week 1-2: Foundation Setting

- Conduct honest assessment of current operations

- Define success metrics and business objectives

- Begin vendor research and create evaluation criteria

Week 3-4: Vendor Evaluation

- Request demos from top 3-5 vendors

- Check references from similar businesses

- Evaluate total cost of ownership, not just initial price

Week 5-8: Decision and Planning

- Make vendor selection based on comprehensive evaluation

- Develop detailed implementation timeline

- Assemble internal project team and define roles

Month 3-6: Implementation Execution

- Follow the phase-by-phase approach outlined above

- Maintain regular communication with all stakeholders

- Document lessons learned for future optimization

The Bottom Line: Your Competitive Advantage Awaits

Here’s the truth that separates thriving e-commerce businesses from struggling ones: warehouse management systems aren’t just operational tools—they’re competitive weapons. When implemented correctly, they transform your entire business from reactive to predictive, from chaotic to systematic, from cost center to profit engine.

Snapdeal’s remarkable turnaround didn’t happen because they got lucky. It happened because they invested in the infrastructure needed to compete at scale. They understood that in today’s e-commerce landscape, operational excellence isn’t optional—it’s the price of admission.

The question isn’t whether you can afford to implement a WMS for Snapdeal-level operations. The question is whether you can afford not to.

Every day you delay implementation is another day your competitors gain ground. Every inefficient process you tolerate is money walking out the door. Every customer disappointed by slow fulfillment or inventory issues is a relationship you may never recover.

But here’s the exciting part: the technology exists today to transform your operations completely. The roadmap is clear, the ROI is proven, and the competitive advantage is waiting for you to claim it.

Ready to transform your warehouse operations and unlock your e-commerce potential? The team at Omneelab has helped hundreds of businesses implement world-class WMS solutions that drive real results. We don’t just sell software—we partner with you to build the operational foundation your business needs to scale successfully.

Contact our WMS experts today to schedule a personalized consultation and discover how the right warehouse management system can revolutionize your e-commerce operations. Your Snapdeal-level transformation starts with a single conversation.

Frequently Asked Questions (FAQs)

Most e-commerce WMS implementations take 4-6 months from contract signing to full operation. Simple cloud-based implementations might complete in 3 months, while complex multi-location deployments can take 12+ months. Companies investing in upfront planning typically see faster, smoother implementations.

The top challenges include integration complexity with existing platforms, data migration accuracy, and staff resistance to change Many businesses underestimate change management and training importance. The key is treating implementation as an organizational change project, not just technology upgrade.

Absolutely! Modern cloud-based WMS solutions offer modular functionality and scalable pricing starting at ₹17,000-42,000 per month Start with core capabilities like inventory management and barcode scanning, then add advanced features as you grow without requiring complete system changes.

Properly implemented WMS integration improves overall performance by automating processes and providing real-time updates However, poor integration can cause processing delays and synchronization issues. Success depends on choosing solutions with robust API capabilities and thorough testing.

While basic inventory systems focus on stock levels and tracking, WMS provides comprehensive warehouse operations management including pick optimization, labor management, and advanced analytics. For businesses processing 100+ orders daily, WMS capabilities become essential for maintaining efficiency and accuracy.

People also read:

- WMS for Nykaa

- JioMart WMS Integration

- Inventory Management with Barcode Technology

- Common Inventory Management Challenges

- WMS for Magento

- WMS for WooCommerce

- WMS for Last Mile in India

- Small Business Barcoding

- Guide to Managing Perishable Inventory

- What Is a Bill of Materials (BOM)? Expert Guide & Tips

Kapil Pathak is a Senior Digital Marketing Executive with over four years of experience specializing in the logistics and supply chain industry. His expertise spans digital strategy, search engine optimization (SEO), search engine marketing (SEM), and multi-channel campaign management. He has a proven track record of developing initiatives that increase brand visibility, generate qualified leads, and drive growth for D2C & B2B technology companies.