For Myntra sellers in India, managing inventory efficiently can be the difference between thriving and merely surviving in the competitive e-commerce landscape. As order volumes increase and customer expectations around delivery speed continue to rise, implementing a robust warehouse management system (WMS) has become not just advantageous but essential for sellers who want to scale their operations.

A warehouse management system specifically tailored for Myntra seller requirements can dramatically transform fulfillment operations, reducing errors, cutting costs, and improving customer satisfaction. Whether you’re managing a small warehouse or operating a full-fledged fulfillment center, the right WMS solution can help you streamline processes from inventory receiving to order shipping while maintaining seamless integration with Myntra’s seller platform.

This comprehensive guide explores everything Indian e-commerce entrepreneurs need to know about selecting, implementing, and optimizing warehouse management systems for Myntra selling operations. We’ll cover the specific challenges Myntra sellers face, the key features to look for in a WMS, integration best practices, and how the right system can transform your e-commerce fulfillment process.

Understanding the Myntra Fulfillment Ecosystem

How Myntra Fulfillment Works for Sellers

Myntra offers sellers multiple fulfillment options that directly impact warehouse management requirements. Primarily, sellers can choose between:

- Myntra Managed Fulfillment: Where Myntra handles storage, packing, and shipping from their facilities.

- Seller Fulfilled Model: Where sellers manage their own warehousing and shipping operations.

For sellers using the second approach, implementing a dedicated WMS becomes crucial. Even those using Myntra’s managed fulfillment often require a WMS to efficiently prepare inventory for dispatch to Myntra’s warehouses and maintain accurate stock records across channels.

A study by the Indian Institute of Management (IIM) found that e-commerce sellers in India who implemented dedicated WMS solutions reported a 37% improvement in order fulfillment speed and a 42% reduction in picking errors.

The Myntra seller ecosystem presents unique challenges including strict service level agreements (SLAs), specific packaging requirements, and complex return processing protocols. A specialized WMS helps address these challenges while ensuring compliance with Myntra’s seller policies.

Key Features to Look for in a WMS for Myntra Sellers

Inventory Management Capabilities

The foundation of any effective warehouse management system for Myntra sellers is robust inventory tracking. Look for systems offering:

- Real-time inventory visibility across multiple storage locations

- Batch and serial number tracking for premium fashion items

- Inventory aging reports to manage seasonal fashion products

- Low stock alerts with automated reorder suggestions

- Inventory forecasting based on historical Myntra sales data

- Multi-warehouse management for sellers operating across regions

According to data from ASCM, proper order processing optimization can reduce warehouse labor costs by up to 30% and improve order accuracy to over 99.5%.

These features help maintain optimal stock levels, reducing both stockouts and excess inventory—particularly important in the fashion e-commerce space where trends change rapidly.

Order Processing Optimization

Myntra’s strict delivery timelines mean order processing efficiency is non-negotiable. An effective WMS should include:

- Direct integration with Myntra Seller Central for automated order import

- Wave planning and batch picking capabilities for high-volume periods

- Pick path optimization to reduce warehouse movement

- Barcode scanning for accurate order fulfillment

- Packing slip generation with Myntra-compliant formatting

- Order prioritization based on promised delivery dates

- Integration with multiple shipping carriers preferred by Myntra

These features ensure orders flow smoothly from receipt to dispatch, maintaining the high fulfillment standards Myntra expects from sellers.

Returns Management

Fashion e-commerce typically experiences higher return rates than other sectors. A WMS for Myntra sellers should offer:

- Streamlined returns receiving processes

- Quality inspection workflows for returned items

- Quick inventory restocking procedures

- Detailed returns analytics to identify problem products

- Integration with Myntra’s return approval system

Efficient returns management helps recover value from returned merchandise and maintains accurate inventory records.

Top WMS Solutions for Myntra Sellers in India

Enterprise Solutions for Large Sellers

For large-scale Myntra sellers handling thousands of orders daily, enterprise-grade WMS solutions offer comprehensive capabilities:

- SAP Extended Warehouse Management: Offers deep integration potential with existing ERP systems and robust multi-channel fulfillment capabilities suitable for sellers operating across multiple e-commerce platforms beyond Myntra.

- Oracle Warehouse Management Cloud: Provides advanced analytics and AI-powered inventory optimization specifically beneficial for fashion inventory with seasonal variations.

While these solutions require significant investment, they deliver sophisticated capabilities for high-volume operations and complex supply chains.

Mid-Market & Small Sellers Options for WMS

For medium-sized Myntra sellers, these options balance functionality with cost-effectiveness:

- Unicommerce: An Indian-developed solution with specific features for e-commerce fulfillment and established Myntra integration pathways.

- Vinculum Vin eRetail WMS: Offers specialized capabilities for fashion inventory management with strong Myntra connectivity.

- Zoho Inventory: Offers basic WMS functionality with e-commerce integrations and affordable pricing tiers.

- Easyship: Combines basic inventory management with shipping optimization features suitable for smaller operations.

These systems may offer fewer advanced features but provide essential functionality at price points accessible to growing businesses.

Best All-in-One WMS Solution for Myntra Sellers in India

If you want a single WMS that does it all for Myntra sellers, Omni WMS is the top choice. It offers seamless Myntra integration, real-time inventory sync, automated order processing, and supports multi-channel fulfillment. Omneelab is scalable for any business size and features an easy-to-use dashboard, making warehouse management simple and efficient. For Myntra sellers in India, Omneelab stands out as the best all-in-one solution to streamline operations and boost growth. Ready to upgrade your warehouse? Book a free call today!

Integrating Your WMS with Myntra Seller Central

Technical Integration Considerations

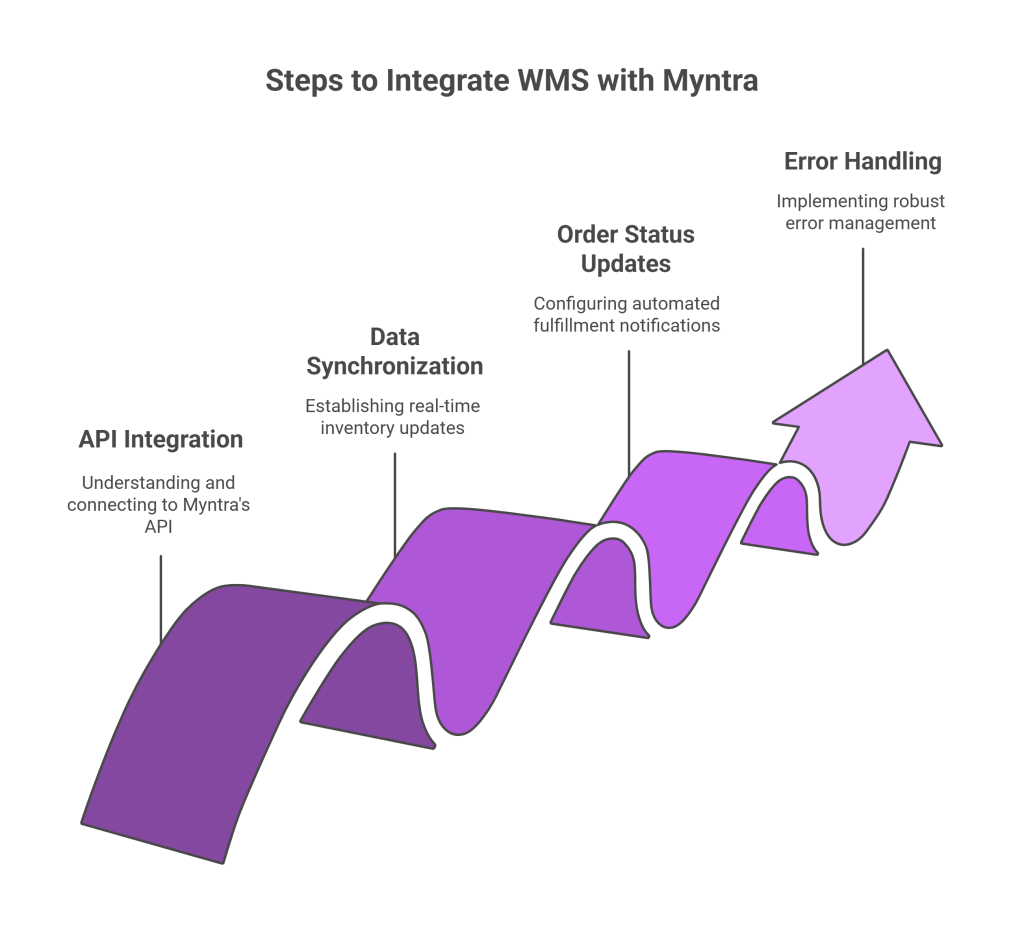

Successfully connecting your WMS with Myntra requires attention to several technical aspects:

- API Integration: Understanding Myntra’s API documentation and ensuring your WMS can connect properly

- Data Synchronization: Establishing protocols for real-time inventory updates between systems

- Order Status Updates: Configuring automated fulfillment status notifications to Myntra

- Error Handling: Implementing robust error management for failed synchronizations

Most established WMS providers have experience with Myntra integration, but it’s important to verify specific capabilities and potentially engage technical specialists for complex implementations.

Integration Best Practices

To ensure smooth operations between your WMS and Myntra seller account:

- Start with thorough testing in a staging environment before going live

- Implement gradual integration, beginning with inventory sync before moving to order processing

- Establish regular data validation protocols to catch discrepancies early

- Create standard operating procedures for handling synchronization issues

- Train warehouse staff on both systems to ensure comprehensive understanding

Proper integration is crucial for maintaining accurate inventory records and meeting Myntra’s fulfillment SLAs.

Automating Your Warehouse Operations for Myntra Orders

Warehouse Automation Technologies

Modern WMS implementations often incorporate automation technologies that can significantly improve efficiency:

- Barcode and RFID Systems: Enable rapid, accurate inventory tracking and order picking

- Mobile Scanning Devices: Allow staff to process orders and update inventory while moving through the warehouse

- Pick-to-Light Systems: Guide pickers with light indicators, particularly useful for fashion items with size/color variations

- Voice-Directed Picking: Enables hands-free, eyes-free picking operations

- Conveyor Systems: Streamline movement of goods in larger warehouses

- Automated Sorting Systems: Particularly valuable for fashion items requiring organization by category, size, or color

These technologies can dramatically improve accuracy and throughput, though implementation costs vary significantly.

Process Automation Through WMS

Beyond physical automation, process automation through your WMS can deliver significant efficiency gains:

- Automated order routing based on inventory location and order priority

- Dynamic slotting that places fast-moving Myntra items in optimal pick locations

- Automated replenishment triggers for pick locations

- Cycle counting schedules that maintain inventory accuracy without disrupting operations

- Labor planning based on predicted Myntra order volumes

- Automated carrier selection based on delivery requirements and costs

Process automation through software often delivers excellent ROI compared to physical automation systems, making it an accessible starting point for many sellers.

Managing Inventory Across Multiple Sales Channels

Multi-Channel Inventory Challenges for Myntra Sellers

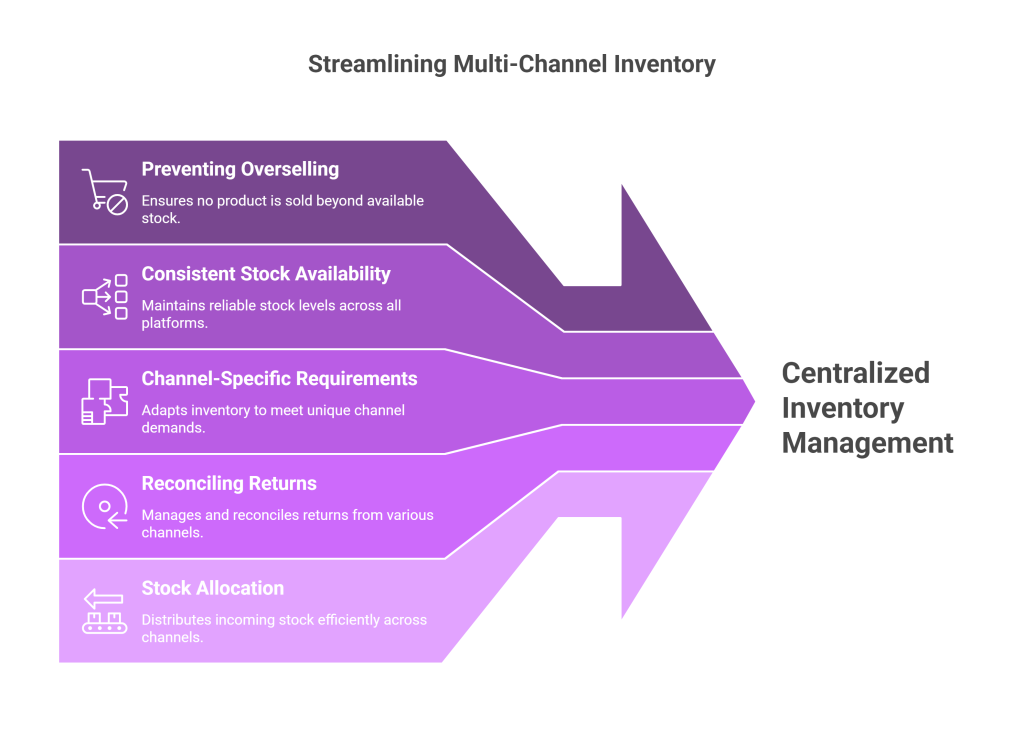

Most Myntra sellers operate across multiple platforms, creating inventory management complexities:

- Preventing overselling across channels

- Maintaining consistent stock availability

- Managing channel-specific inventory requirements

- Reconciling inventory after returns from different platforms

- Allocating incoming stock appropriately across channels

A sophisticated WMS helps address these challenges through centralized inventory management with channel-specific rules.

Unified Inventory Strategies

To effectively manage inventory across Myntra and other sales channels:

- Implement real-time inventory synchronization across all platforms

- Establish buffer stock policies for each channel based on sales velocities

- Create channel prioritization rules for limited stock situations

- Develop unified SKU naming conventions across all platforms

- Implement regular cross-channel inventory reconciliation procedures

These strategies help maintain inventory accuracy while maximizing sales opportunities across all platforms including Myntra.

Measuring WMS Performance for Myntra Fulfillment

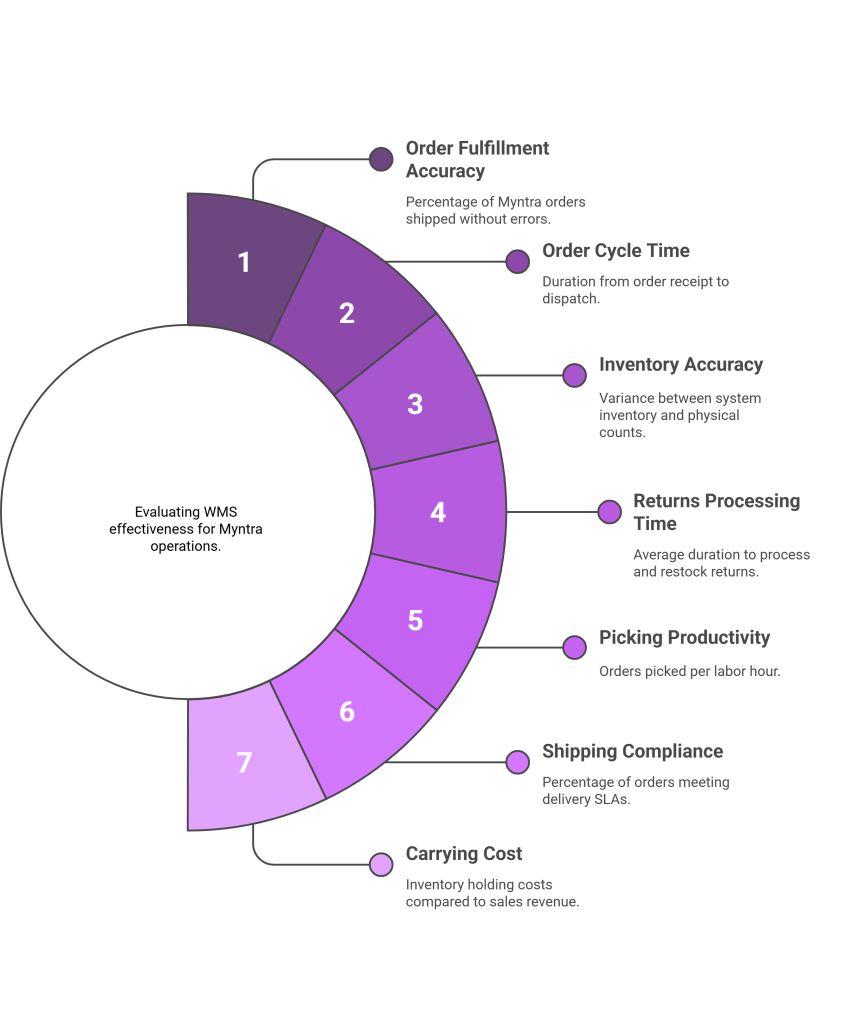

Key Performance Indicators

Tracking these metrics helps evaluate WMS effectiveness specifically for Myntra operations:

- Order Fulfillment Accuracy: Percentage of Myntra orders shipped without errors

- Order Cycle Time: Duration from order receipt to dispatch

- Inventory Accuracy: Variance between system inventory and physical counts

- Returns Processing Time: Average duration to process and restock Myntra returns

- Picking Productivity: Orders picked per labor hour

- Shipping Compliance: Percentage of orders meeting Myntra’s delivery SLAs

- Carrying Cost: Inventory holding costs compared to sales revenue

Establishing baselines and improvement targets for these KPIs helps quantify the ROI of your WMS implementation.

Continuous Improvement Strategies

Effective WMS utilization requires ongoing refinement:

- Regular analysis of performance metrics to identify bottlenecks

- Periodic warehouse layout optimization based on changing product velocities

- Staff retraining on system functionality and process updates

- Regular WMS software updates to access new features

- Cross-functional improvement teams including warehouse staff and system administrators

The most successful Myntra sellers view their WMS not as a static solution but as an evolving system requiring continuous optimization.

Supply Chain Integration Beyond the Warehouse

Connecting WMS with Broader Supply Chain Systems

For maximum efficiency, your WMS should connect with other supply chain components:

- Supplier Management Systems: For streamlined inbound inventory planning

- Transportation Management Systems: To optimize shipping costs and delivery times

- Returns Management Systems: For efficient processing of customer returns

- Business Intelligence Platforms: For advanced analytics and forecasting

These integrations create a seamless information flow throughout your supply chain, reducing friction points and improving decision-making.

Myntra-Specific Supply Chain Considerations

Selling on Myntra introduces specific supply chain requirements that your WMS should accommodate:

- Managing split shipments for multi-item orders

- Handling Myntra’s specific packaging requirements

- Coordinating with Myntra-approved shipping partners

- Supporting Myntra’s quality control processes

- Accommodating Myntra-specific promotional events like End of Reason Sale

A WMS with flexibility to adapt to these requirements ensures smooth operations within Myntra’s ecosystem.

Future Trends in WMS for E-Commerce in India

Emerging Technologies

Forward-thinking Myntra sellers should be aware of these emerging WMS capabilities:

- AI-Powered Demand Forecasting: Using machine learning for more accurate inventory planning

- Robotic Process Automation: For repetitive warehouse tasks

- Augmented Reality: Enhancing picking accuracy and training

- Blockchain Integration: For improved supply chain transparency

- IoT Sensors: For real-time environmental monitoring of sensitive fashion items

While not all these technologies may be immediately applicable, understanding future directions helps inform long-term WMS strategy.

The Growing Role of Data Analytics

Advanced analytics are becoming increasingly central to WMS capabilities:

- Predictive analytics for demand forecasting specific to Myntra customer preferences

- Pattern recognition to identify operational inefficiencies

- Scenario modeling for warehouse layout optimization

- Customer behavior analysis to inform stocking decisions

- Seasonality modeling for fashion inventory management

Data-driven warehouse management represents the future of e-commerce fulfillment, particularly for fashion platforms like Myntra with complex seasonal patterns.

Conclusion

Implementing a warehouse management system specifically optimized for Myntra selling operations can transform your e-commerce business, enabling faster growth, improved customer satisfaction, and higher profitability. The right solution depends on your business size, order volume, and specific operational challenges.

Whether you’re considering your first WMS implementation or upgrading an existing system, focus on Myntra-specific requirements, seamless integration capabilities, and scalability to support your business growth. Remember that successful WMS implementation involves not just software selection but also process redesign, staff training, and continuous improvement.

By strategically investing in warehouse management technology tailored to Myntra’s ecosystem, sellers can gain a significant competitive advantage in India’s rapidly evolving e-commerce marketplace.

Frequently Asked Questions

Myntra offers two main fulfillment options: Myntra Managed Fulfillment (where Myntra handles storage, packing, and shipping from their warehouses) and the Seller Fulfilled Model (where sellers manage their own operations). With Myntra Managed Fulfillment, sellers simply ship inventory to Myntra’s facilities, while the Seller Fulfilled Model requires robust WMS capabilities to meet Myntra’s strict SLAs and delivery timelines.

Omneelab WMS stands out as the premier solution for Myntra sellers, offering seamless integration and comprehensive features for Indian businesses of all sizes. For larger operations, alternatives like SAP, Unicommerce, Vinculum Vin eRetail WMS, Zoho InventoryOracle WMS provide robust enterprise capabilities. The ideal system should support direct Myntra integration, fashion inventory management, and scalability to grow with your business.

WMS integration with Myntra works through their API, establishing connections for inventory synchronization and order management. The process involves mapping your product catalog, configuring real-time data synchronization, and setting up automated order status updates. Most established WMS providers offer pre-built Myntra integration modules, and working with integration specialists can ensure a smooth implementation.

A WMS optimized for Myntra fulfillment delivers faster order processing, reduced error rates, improved inventory accuracy, and optimized space utilization. It enables enhanced workforce productivity through streamlined workflows, better returns management, and detailed analytics for continuous improvement. Most importantly, it helps maintain Myntra’s required service levels, protecting your seller rating and platform visibility.

Effective Myntra returns management requires dedicated receiving areas, systematic quality inspection protocols, and automated inventory updates. Your WMS should integrate with Myntra’s return approval system, support required documentation, and provide analytics to identify return patterns. Proper returns processing not only recovers product value but maintains inventory accuracy and customer satisfaction—critical for sustained success on the Myntra platform.

People also read:

- Last Mile Delivery Stations in India

- WMS for BigCommerce

- WMS for Last Mile in India

- Small Business Barcoding

- Demand-driven Replenishment Practices for Retailers

- Guide to Managing Perishable Inventory

- What Is a Bill of Materials (BOM)? Expert Guide & Tips

- Inventory Management with Barcode Technology

- Common Inventory Management Challenges

- Comprehensive Guide to Inventory Management Systems

- Manual and Automated Inventory Management

- Top 10 Tips for Warehouse Management Software

Kapil Pathak is a Senior Digital Marketing Executive with over four years of experience specializing in the logistics and supply chain industry. His expertise spans digital strategy, search engine optimization (SEO), search engine marketing (SEM), and multi-channel campaign management. He has a proven track record of developing initiatives that increase brand visibility, generate qualified leads, and drive growth for D2C & B2B technology companies.