Have you ever wondered how your contactless payment card works so seamlessly? Or how major retailers can track thousands of products instantly without scanning each barcode individually? The answer lies in RFID technology – a revolutionary system that’s quietly transforming how businesses operate across every industry imaginable.

Radio frequency identification (RFID) isn’t just another tech buzzword; it’s a game-changing technology that’s reshaping everything from healthcare to manufacturing, retail to logistics. In this comprehensive guide, we’ll explore what RFID is, dive deep into how it functions, and uncover why virtually every industry is embracing this powerful automation technology.

Understanding RFID Technology: The Basics

What is RFID? At its core, RFID technology is an automatic identification system that uses electromagnetic fields to identify and track tags attached to objects, animals, or people. Think of it as a more sophisticated cousin of the barcode system, but one that doesn’t require direct line-of-sight scanning.

The beauty of RFID systems lies in their simplicity and efficiency. Unlike traditional barcodes that need to be individually scanned, RFID tags can be read from several feet away, and multiple tags can be processed simultaneously. This contactless technology has become the backbone of modern supply chain visibility and asset tracking systems.

RFID technology operates on a simple principle: when an RFID tag comes within range of an RFID reader, it transmits its stored data wirelessly. This seamless data capture system enables real-time monitoring and tracking capabilities that were previously impossible or extremely labor-intensive.

How RFID Functions: A Deep Dive into the Technology

Understanding how RFID works requires breaking down the system into its core components and examining the step-by-step process of data transmission.

Essential RFID System Components

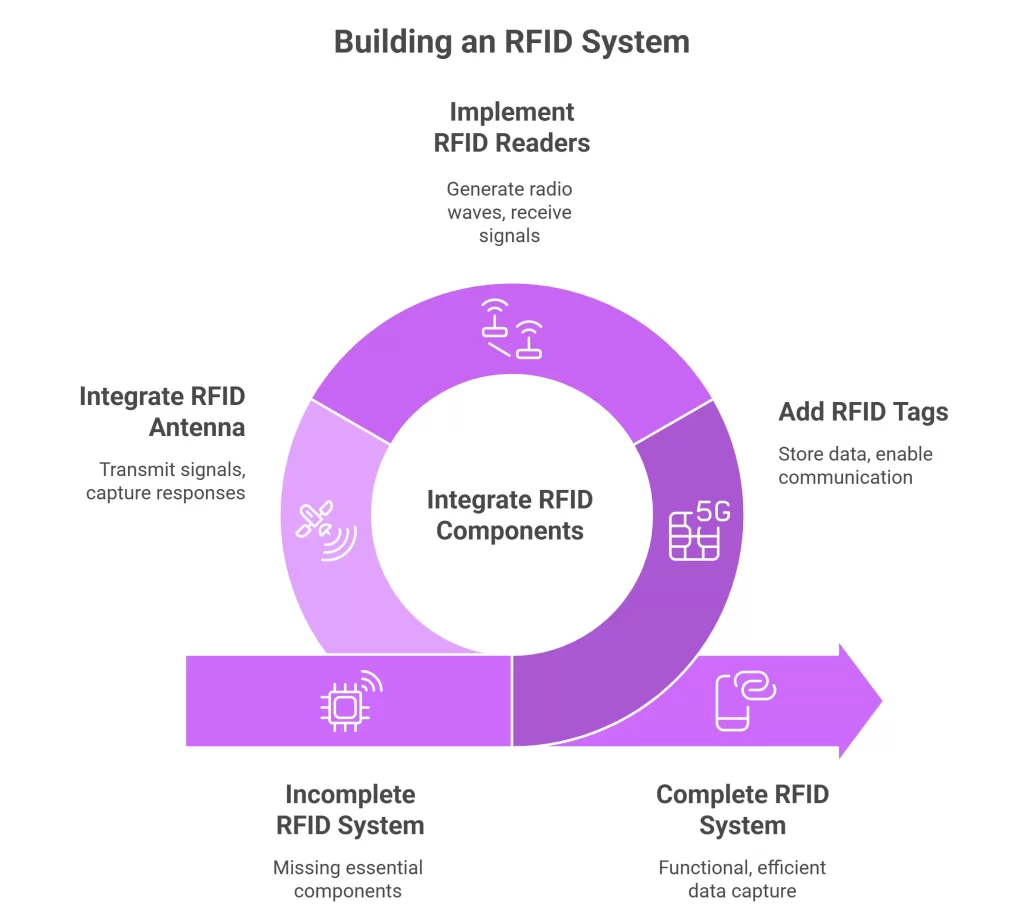

Every RFID system consists of three fundamental elements:

- RFID Tags (Transponders): These small electronic devices contain a microchip and antenna. The chip stores data (typically an identification number), while the antenna enables communication with RFID readers through electromagnetic fields.

- RFID Readers (Interrogators): These devices generate radio waves and receive signals back from RFID tags. Modern RFID readers can process hundreds of tags per second, making them incredibly efficient for high-volume applications.

- RFID Antenna: Often integrated into the reader, the antenna transmits radio frequency signals and captures responses from nearby tags. The antenna’s design directly impacts the system’s read range and accuracy.

The RFID Communication Process

Here’s how RFID technology work step by step:

- Signal Generation: The RFID reader generates electromagnetic fields through its antenna

- Tag Activation: When an RFID tag enters this field, it becomes energized (for passive tags) or responds with its own signal (for active tags)

- Data Transmission: The tag transmits its stored information back to the reader

- Data Processing: The reader captures this information and forwards it to the backend system for processing

- Action Execution: The system takes appropriate action based on the received data

The global RFID market is projected to reach $40.5 billion by 2025, growing at a compound annual growth rate (CAGR) of 12.1% from 2020 to 2025. This explosive growth reflects the technology’s proven value across multiple industries and applications.

Types of RFID Systems

RFID frequency bands determine the system’s capabilities and applications:

- Low Frequency (LF) RFID: Operating at 125-134 kHz, these systems offer short read ranges but work well around metals and liquids. They’re commonly used in animal identification and access control systems.

- High Frequency (HF) RFID: Operating at 13.56 MHz, HF systems provide moderate read ranges and are widely used in smart cards, library management, and near field communication applications.

- Ultra High Frequency (UHF) RFID: Operating at 860-960 MHz, UHF systems offer the longest read ranges and fastest data transfer rates, making them ideal for supply chain management and inventory tracking.

Active vs Passive RFID Tags

Passive RFID tags don’t have their own power source and rely on energy from the reader’s electromagnetic field. They’re cost-effective, have longer lifespans, and are perfect for most tracking applications.

Active RFID tags contain their own battery, enabling longer read ranges and additional features like sensors. While more expensive, they’re essential for applications requiring extended range or real-time location tracking.

RFID Applications Across Industries

The versatility of RFID technology has led to its adoption across virtually every sector. Let’s explore how different industries are leveraging this powerful tool.

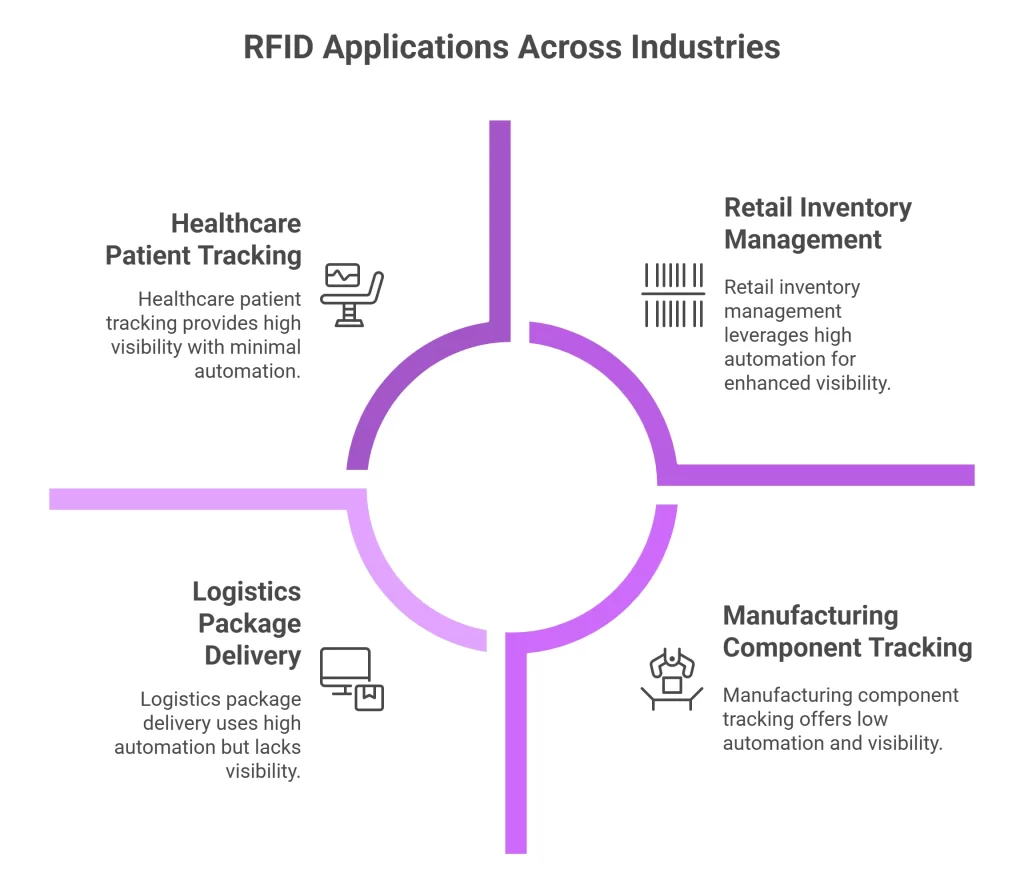

Retail Industry Revolution

RFID in retail industry has transformed how stores manage inventory and enhance customer experiences. Major retailers like Walmart and Zara use RFID tags to achieve near-perfect inventory accuracy, reducing stockouts and overstock situations.

The technology enables instant inventory counts, automated reordering, and improved loss prevention. Customers benefit from better product availability and faster checkout processes through RFID-enabled self-service options.

Healthcare Transformation

RFID in healthcare addresses critical challenges in patient safety and asset management. Hospitals use RFID tracking to monitor medical equipment, ensuring life-saving devices are always available when needed.

Patient identification through RFID wristbands reduces medication errors and improves treatment accuracy. The technology also enables real-time monitoring of high-value medical assets, reducing equipment loss and maintenance costs. For specialized applications, pharmaceutical warehouse management systems integrate RFID for enhanced compliance and tracking.

Manufacturing Excellence

RFID in manufacturing streamlines production processes and enhances quality control. Manufacturers attach RFID tags to components and finished products, enabling real-time tracking throughout the production lifecycle.

This automation technology provides unprecedented visibility into work-in-progress inventory, reduces manual data entry errors, and enables predictive maintenance of manufacturing equipment.

Logistics and Supply Chain

RFID in logistics has revolutionized package tracking and delivery operations. The technology provides end-to-end supply chain visibility, enabling companies to track products from manufacturing to final delivery.

Real-time monitoring capabilities help logistics providers optimize routes, reduce delivery times, and provide customers with accurate tracking information. This level of transparency has become a competitive advantage in today’s e-commerce-driven marketplace, especially when integrated with modern warehouse management solutions.

Why Every Industry Needs RFID Technology

The compelling RFID benefits extend far beyond simple tracking capabilities. Here’s why businesses across all sectors are embracing this technology:

Operational Efficiency Gains

RFID implementation dramatically reduces manual labor requirements. Tasks that previously took hours, such as inventory counts, can now be completed in minutes. This efficiency gain translates directly to cost savings and improved productivity.

The technology eliminates human errors associated with manual data entry, ensuring higher data accuracy and reducing costly mistakes. Automated data capture systems provide real-time information, enabling faster decision-making and improved operational responsiveness. Organizations can further enhance efficiency by implementing automated inventory management systems alongside RFID technology.

Companies implementing RFID technology typically achieve 95-99% inventory accuracy rates, compared to 65-75% accuracy with traditional barcode systems. This dramatic improvement translates to significant cost savings and operational efficiency gains.

Enhanced Customer Experience

Modern consumers expect seamless, fast service. RFID solutions enable businesses to meet these expectations by reducing wait times, improving product availability, and providing accurate information instantly.

In retail environments, RFID enables features like smart fitting rooms, where customers can see product information and request different sizes without leaving the room. This level of service differentiation creates competitive advantages and improves customer loyalty.

Cost Reduction and ROI

While RFID cost considerations are important, the technology typically delivers strong returns on investment. Reduced labor costs, improved inventory accuracy, and decreased shrinkage often justify implementation expenses within 12-18 months.

The technology also reduces indirect costs such as stockouts, overstock situations, and manual process errors. These hidden savings often exceed the direct labor cost reductions, making RFID implementation even more attractive. Understanding inventory shrinkage prevention becomes crucial when calculating RFID ROI.

Security and Loss Prevention

RFID security features help businesses protect valuable assets and reduce theft. The technology enables real-time alerts when tagged items move unexpectedly, providing immediate notification of potential security breaches.

Unlike traditional security tags, RFID systems can track items throughout their entire lifecycle, making it much more difficult for thieves to remove or disable protection mechanisms.

RFID vs Traditional Methods: A Comparative Analysis

Understanding the advantages of RFID vs barcode technology helps businesses make informed implementation decisions.

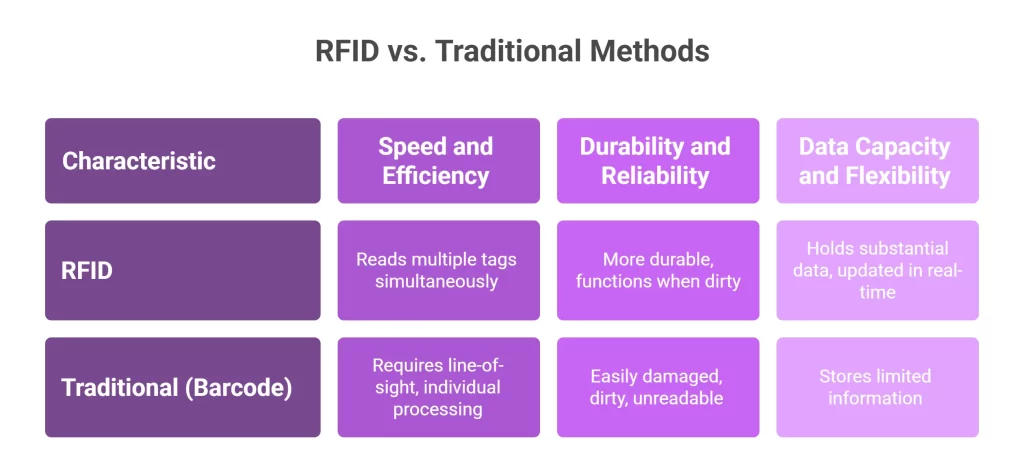

Speed and Efficiency

Traditional barcode scanning requires line-of-sight access and individual item processing. RFID tracking systems can read multiple tags simultaneously from several feet away, dramatically increasing processing speed.

A single RFID reader can process hundreds of tags per second, while barcode scanning typically handles 1-2 items per second. This speed difference becomes crucial in high-volume environments like distribution centers or retail stores. For businesses comparing technologies, our guide on inventory management with barcode technology provides detailed insights.

Durability and Reliability

Barcodes can become damaged, dirty, or unreadable, causing scanning failures. RFID chips are more durable and can function even when tags are dirty, damaged, or obscured by other materials.

The wireless nature of RFID communication eliminates many failure points associated with physical scanning systems, resulting in higher reliability and fewer operational disruptions.

Data Capacity and Flexibility

While barcodes store limited information, RFID tags can hold substantial amounts of data and can be updated in real-time. This capability enables dynamic applications like tracking product history, maintenance records, or changing status information.

Implementation Considerations and Best Practices

Successful RFID implementation requires careful planning and consideration of various factors:

System Design and Integration

Effective RFID solutions require seamless integration with existing business systems. RFID middleware software serves as the bridge between RFID hardware and enterprise applications, ensuring smooth data flow and system compatibility.

Businesses must consider factors like read range requirements, tag placement, and environmental conditions when designing their systems. Proper planning prevents costly redesigns and ensures optimal performance. When selecting systems, consider choosing the right warehouse management solution that supports RFID integration.

Compliance and Standards

RFID compliance standards ensure interoperability and consistent performance across different systems and vendors. Key standards include EPC Global for supply chain applications and ISO standards for various industry-specific requirements.

Understanding and adhering to relevant standards protects investment and ensures future compatibility as technology evolves.

Privacy and Security Considerations

RFID privacy concerns must be addressed through proper system design and security measures. Businesses should implement encryption, access controls, and data protection protocols to safeguard sensitive information.

RFID blocking technology and privacy policies help address consumer concerns about unauthorized tracking or data collection.

The Future of RFID Technology

Future of RFID technology points toward increased integration with emerging technologies and expanded applications:

IoT Integration

IoT integration with RFID systems creates powerful platforms for smart manufacturing, intelligent supply chains, and connected retail environments. This convergence enables predictive analytics, automated decision-making, and enhanced operational intelligence.

Advanced Analytics and AI

The massive amounts of data generated by RFID systems provide valuable inputs for artificial intelligence and machine learning applications. These technologies can identify patterns, predict trends, and optimize operations in ways previously impossible.

Emerging Applications

New applications continue to emerge as RFID technology becomes more sophisticated and cost-effective. Areas like smart cities, environmental monitoring, and personalized healthcare represent significant growth opportunities. The future of warehouse management trends shows increasing RFID adoption across industries.

Conclusion: Embracing the RFID Revolution

RFID technology represents more than just an upgrade to existing tracking methods – it’s a fundamental shift toward automated, intelligent business operations. The technology’s ability to provide real-time visibility, reduce costs, and enhance customer experiences makes it essential for businesses seeking competitive advantages in today’s fast-paced marketplace.

Whether you’re managing inventory in a retail store, tracking assets in a hospital, or optimizing production in a manufacturing facility, RFID solutions offer compelling benefits that justify implementation costs. The key to success lies in understanding your specific requirements, choosing appropriate technology components, and planning for seamless integration with existing systems.

For businesses looking to maximize their RFID investment, integrating with advanced warehouse management systems like OmneeLab WMS can unlock even greater potential . OmneeLab’s sophisticated WMS platform seamlessly integrates with RFID technology to create a precision-engineered fulfillment machine, enabling superhuman tracking capabilities that can locate any item in a 100,000 sq ft warehouse in under 30 seconds . This powerful combination transforms traditional warehouses into intelligent, automated operations that deliver exceptional accuracy and efficiency across all fulfillment processes.

As we move toward an increasingly connected and automated future, businesses that embrace RFID technology today will be better positioned to capitalize on tomorrow’s opportunities. The question isn’t whether your industry needs RFID – it’s how quickly you can implement it to start realizing its transformative benefits.

Ready to explore how RFID technology can transform your business operations? Consider consulting with RFID specialists to assess your specific needs and develop an implementation strategy that delivers maximum value for your investment.

Frequently Asked Questions (FAQs)

RFID works in four simple steps: The reader generates electromagnetic fields, tags get activated when entering this field, they transmit stored data wirelessly back to the reader, and the system processes this information for immediate action. This entire process happens in milliseconds, enabling real-time tracking capabilities.

Passive RFID tags rely on the reader’s energy field and are cost-effective with 20-year lifespans. Active RFID tags have their own battery, offering longer read ranges (up to 100 meters) and additional features like sensors, but cost more and are ideal for large facility tracking applications.

Yes, RFID operates independently using radio frequency signals, not internet protocols. However, internet connectivity is needed for cloud integration, remote monitoring, or real-time analytics. Many businesses collect RFID data locally and sync with online systems when connectivity is available.

Metals reflect radio waves, liquids absorb RF energy, and dense materials like concrete can interfere with RFID signals. However, specialized tags designed for metal surfaces and liquid environments are available, and proper system design can overcome most environmental challenges.

RFID achieves 95-99% accuracy versus barcodes’ 85-95% accuracy. RFID’s superior performance comes from simultaneous multi-tag reading without line-of-sight requirements, continuous tracking capabilities, and reduced human scanning errors, making it ideal for inventory management and asset tracking.

Kapil Pathak is a Senior Digital Marketing Executive with over four years of experience specializing in the logistics and supply chain industry. His expertise spans digital strategy, search engine optimization (SEO), search engine marketing (SEM), and multi-channel campaign management. He has a proven track record of developing initiatives that increase brand visibility, generate qualified leads, and drive growth for D2C & B2B technology companies.