Have you ever wondered how major logistics companies maintain seamless operations during shift changes, equipment transfers, or facility handovers? The answer lies in a critical process called HOTO in logistics – a systematic approach that ensures operational continuity when responsibilities change hands.

In today’s fast-paced supply chain environment, even a minor disruption during operational transitions can cost companies thousands of dollars and damage customer relationships. According to a recent study by McKinsey & Company, supply chain disruptions cost companies an average of $184 million annually, with poor handover procedures being a significant contributing factor. That’s where handover takeover operations become your secret weapon for maintaining efficiency and preventing costly mistakes.

This comprehensive guide will walk you through everything you need to know about HOTO supply chain procedures, from basic definitions to advanced implementation strategies. Whether you’re a logistics manager, supply chain professional, or warehouse supervisor, you’ll discover practical insights to streamline your operations and boost efficiency.

What Does HOTO Stand For in Logistics?

HOTO stands for Handover Takeover Operations – a structured process that ensures smooth transitions of responsibilities, assets, or operations from one party to another within the logistics and supply chain ecosystem. Think of it as passing the baton in a relay race, but with detailed documentation and verification steps to prevent any drops.

In the logistics world, HOTO procedures are essential whenever there’s a change in:

- Shift personnel in warehouses or distribution centers

- Equipment operators for machinery or vehicles

- Facility management during acquisitions or partnerships

- Third-party logistics providers (3PL transitions)

- Technology systems during upgrades or migrations

The beauty of HOTO logistics lies in its systematic approach. Instead of hoping everything goes smoothly during transitions, companies create detailed protocols that eliminate guesswork and reduce operational risks.

Why HOTO is Critical for Modern Supply Chain Operations

Operational Continuity Protection

Imagine a 24/7 distribution center where the night shift supervisor leaves without properly briefing the morning team about a critical shipment delay. The result? Confused staff, delayed deliveries, and frustrated customers. Supply chain continuity depends on seamless information transfer during these transitions.

Research from the Council of Supply Chain Management Professionals (CSCMP) reveals that companies with standardized handover procedures experience 23% fewer operational disruptions compared to those relying on informal communication methods.

HOTO in logistics prevents these scenarios by establishing clear communication channels and documentation requirements. When implemented correctly, it ensures that critical information never gets lost in translation.

Risk Mitigation and Compliance

Modern logistics operations face increasing regulatory scrutiny, especially in industries like pharmaceuticals, food, and hazardous materials. HOTO protocol helps companies maintain compliance by creating audit trails and ensuring that safety procedures are consistently followed across all operational transitions.

Consider a pharmaceutical warehouse handling temperature-sensitive medications. Without proper warehouse handover procedures, a new shift might not understand critical storage requirements, potentially compromising product integrity and regulatory compliance.

Enhanced Accountability and Performance

HOTO procedures create clear accountability structures by documenting who’s responsible for what during transitions. This transparency improves performance tracking and helps identify areas for operational improvement.

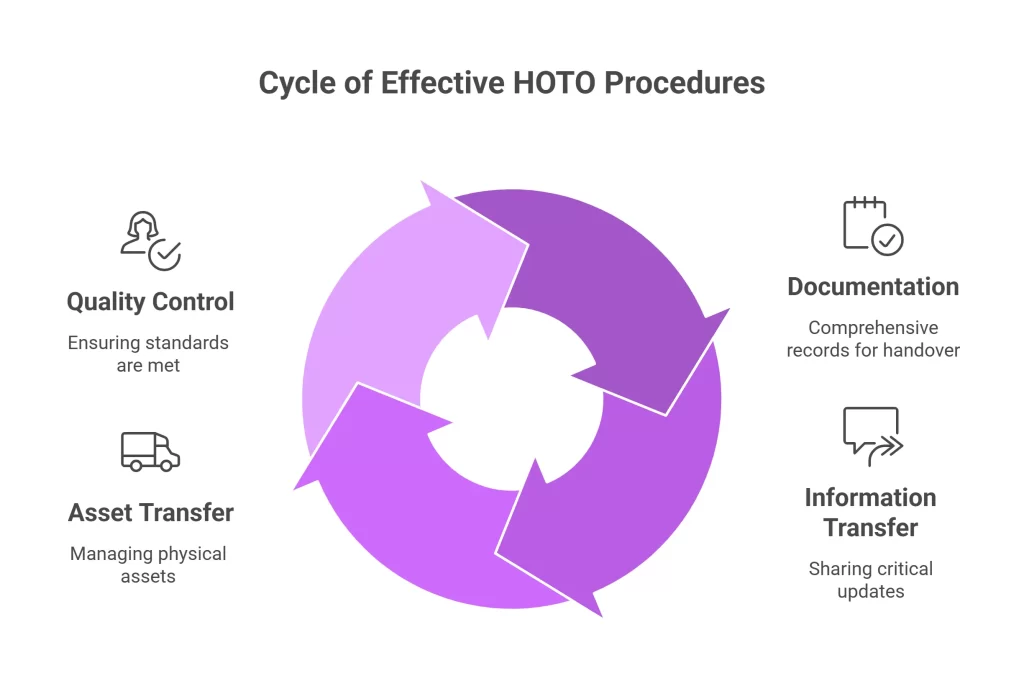

Core Components of Effective HOTO Procedures

Documentation and Information Transfer

The foundation of successful logistics handover process lies in comprehensive documentation. This includes:

Operational Status Reports:

- Current inventory levels and locations

- Equipment status and maintenance schedules

- Ongoing shipments and delivery commitments

- Safety incidents or concerns

- Performance metrics and KPIs

Critical Information Handoffs:

- Customer-specific requirements or issues

- Vendor communications and updates

- System alerts or technical problems

- Staffing changes or training needs

Asset Transfer Logistics

Physical assets require special attention during HOTO implementation. This includes:

Equipment Verification:

- Condition assessments

- Maintenance records

- Operational parameters

- Safety compliance checks

Inventory Management:

- Stock counts and reconciliation

- Location verification

- Quality control status

- Damage or discrepancy reports

Quality Control Handover

Maintaining quality standards during transitions is crucial for supply chain transitions. Effective quality control includes:

- Process verification to ensure procedures are followed correctly

- Performance benchmarking against established standards

- Issue escalation protocols for handling problems

- Continuous improvement feedback loops

Step-by-Step HOTO Implementation Guide

Phase 1: Planning and Preparation

Before implementing HOTO best practices, organizations need to establish clear frameworks:

1. Define Scope and Objectives Start by identifying which operations require formal handover procedures. Not every task needs the full HOTO treatment – focus on critical processes that impact customer service, safety, or compliance.

2. Develop Standard Operating Procedures (SOPs) Create detailed supply chain process documentation that outlines:

- Pre-handover preparation steps

- Information transfer requirements

- Verification and sign-off procedures

- Post-handover follow-up activities

3. Design Documentation Templates Standardized forms and checklists ensure consistency across all handovers. These templates should capture essential information while remaining user-friendly for busy operational staff.

Phase 2: Technology Integration

Modern digital logistics transformation has revolutionized HOTO procedures through:

Automated Handover Systems:

- Digital dashboards displaying real-time operational status

- Automated alerts for critical issues or deadlines

- Electronic signature capabilities for accountability

- Integration with existing warehouse management systems (WMS)

According to Deloitte’s 2024 Global Supply Chain Survey, organizations using digital handover systems report 31% improvement in transition accuracy and 28% reduction in handover-related errors.

Mobile Solutions:

- Tablet or smartphone apps for field-based handovers

- Photo documentation capabilities

- GPS tracking for asset locations

- Offline functionality for areas with poor connectivity

Phase 3: Training and Change Management

Successful HOTO implementation requires comprehensive training programs:

Staff Education:

- Understanding the importance of proper handovers

- Step-by-step procedure training

- Technology system usage

- Problem escalation protocols

Change Management Logistics:

- Addressing resistance to new procedures

- Highlighting benefits for individual workers

- Creating feedback mechanisms for continuous improvement

- Recognizing and rewarding compliance

HOTO Best Practices for Different Logistics Scenarios

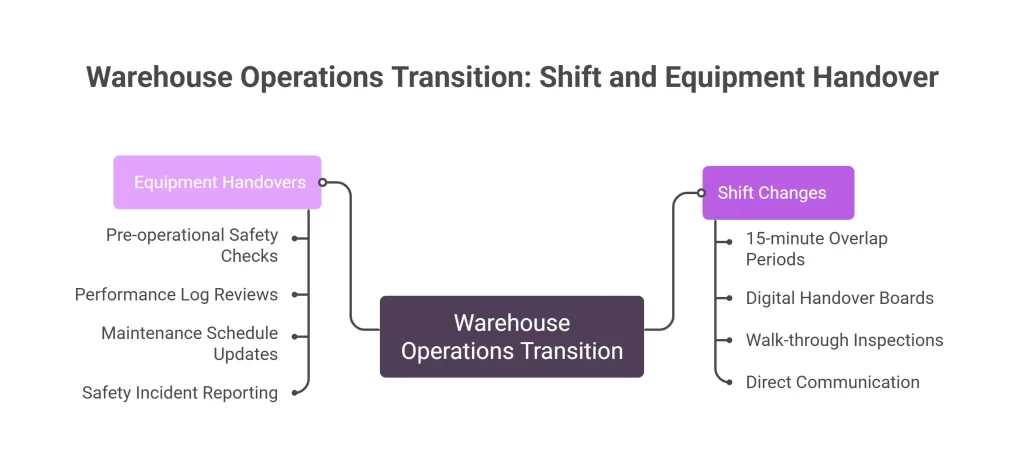

Warehouse Operations Transition

Shift Changes: Warehouse operations typically run 24/7, making shift handover procedures critical for maintaining productivity. Effective practices include:

- 15-minute overlap periods where outgoing and incoming supervisors review operations together

- Digital handover boards displaying key metrics and ongoing issues

- Walk-through inspections of critical areas and equipment

- Direct communication about customer priorities or special handling requirements

Equipment Handovers: When operators change shifts on forklifts, conveyor systems, or automated equipment:

- Pre-operational safety checks to verify equipment condition

- Performance log reviews to identify any operational issues

- Maintenance schedule updates to ensure timely service

- Safety incident reporting to maintain awareness of potential hazards

Transportation and Fleet Management

Driver Changes: Long-haul transportation often requires driver changes at specific locations. HOTO procedures for fleet operations include:

- Vehicle inspection reports documenting condition and any issues

- Load verification to ensure cargo integrity and security

- Route and delivery updates including customer communications

- Fuel and maintenance records for operational efficiency

Fleet Transitions: When vehicles move between different operational units or companies:

- Comprehensive condition assessments with photo documentation

- Maintenance history transfers to ensure service continuity

- Insurance and registration verification for compliance

- Driver qualification checks for authorized personnel

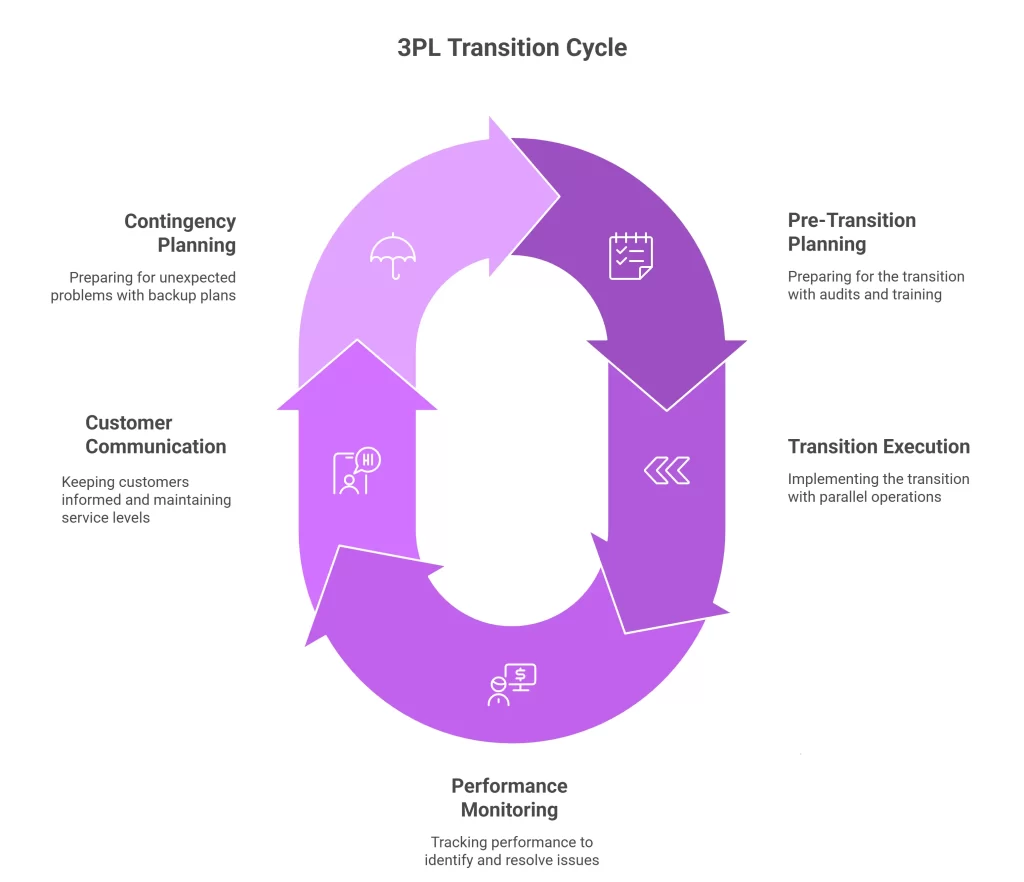

Third-Party Logistics (3PL) Transitions

Provider Changes: Switching between logistics providers requires extensive HOTO protocol implementation:

Pre-Transition Planning:

- 60-90 day preparation periods for complex operations

- Detailed inventory audits to establish baseline conditions

- System integration testing to ensure data continuity

- Staff training programs for new procedures and systems

Transition Execution:

- Parallel operations during initial phases to minimize risk

- Daily performance monitoring to identify issues quickly

- Customer communication protocols to maintain service levels

- Contingency planning for unexpected problems

Technology Solutions for Modern HOTO Operations

Digital HOTO Systems

The evolution toward automated handover systems has transformed traditional paper-based processes into streamlined digital workflows:

Cloud-Based Platforms: Modern HOTO software solutions offer:

- Real-time data synchronization across multiple locations

- Mobile accessibility for field operations

- Integration with existing ERP and WMS systems

- Advanced analytics for performance optimization

Internet of Things (IoT) Integration: Smart sensors and connected devices enhance HOTO procedures by:

- Automatically capturing equipment status and performance data

- Providing real-time alerts for maintenance needs or operational issues

- Creating detailed audit trails for compliance purposes

- Enabling predictive maintenance scheduling

Artificial Intelligence and Machine Learning

AI-Powered HOTO Optimization: Advanced systems use machine learning to:

- Identify patterns in handover data to predict potential issues

- Automatically generate handover reports based on operational data

- Optimize timing and resource allocation for transitions

- Provide intelligent recommendations for process improvements

Natural Language Processing: AI systems can analyze handover communications to:

- Extract key information from unstructured text

- Identify potential risks or concerns mentioned in reports

- Generate summaries of complex operational situations

- Translate communications between different languages or technical levels

Common HOTO Challenges and Solutions

Communication Barriers

Challenge: Information gets lost or misunderstood during handovers, especially in multilingual environments or complex technical situations.

Solution: Implement standardized communication protocols that include:

- Visual aids and diagrams for complex procedures

- Multilingual documentation for diverse workforces

- Verification steps to ensure understanding

- Clear escalation paths for questions or concerns

Time Constraints

Challenge: Operational pressures often lead to rushed handovers that skip critical steps.

Solution: Design efficient HOTO procedures that balance thoroughness with practicality:

- Prioritize critical information and processes

- Use technology to automate routine data collection

- Create abbreviated procedures for low-risk situations

- Build handover time into operational schedules

Resistance to Change

Challenge: Staff may resist new procedures, especially if they perceive them as bureaucratic or time-consuming.

Solution: Focus on change management logistics strategies:

- Clearly communicate the benefits of proper handovers

- Involve staff in procedure development and refinement

- Provide adequate training and support

- Recognize and reward compliance with new procedures

Understanding common inventory management challenges can help organizations address similar issues that arise during HOTO implementation.

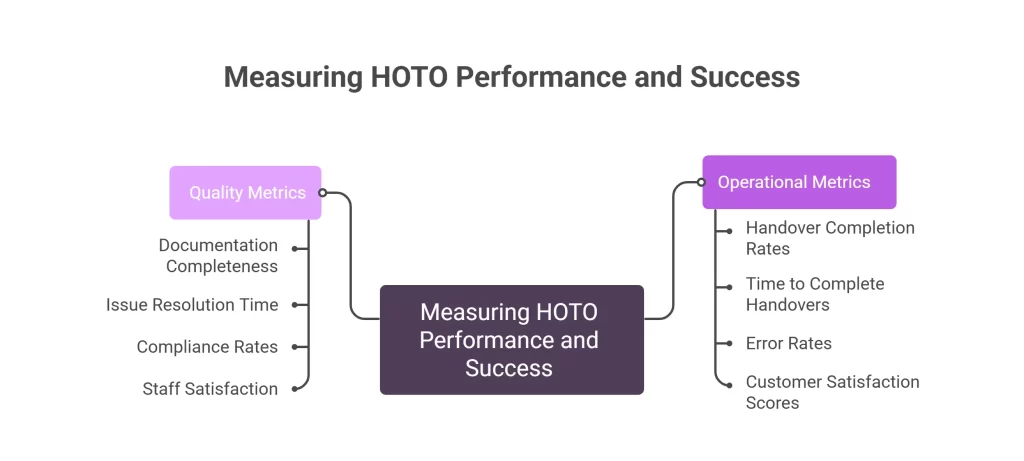

Measuring HOTO Performance and Success

Key Performance Indicators (KPIs)

Effective logistics KPI tracking for HOTO procedures includes:

Operational Metrics:

- Handover completion rates – percentage of transitions completed according to protocol

- Time to complete handovers – efficiency of the process

- Error rates – incidents or problems arising from incomplete handovers

- Customer satisfaction scores – impact on service quality

Quality Metrics:

- Documentation completeness – thoroughness of handover records

- Issue resolution time – speed of addressing problems identified during handovers

- Compliance rates – adherence to regulatory or company requirements

- Staff satisfaction – employee feedback on HOTO procedures

Continuous Improvement Strategies

Regular Reviews and Updates:

- Monthly analysis of HOTO performance data

- Quarterly procedure reviews and updates

- Annual comprehensive assessments

- Ongoing staff feedback collection

Benchmarking and Best Practice Sharing:

- Industry standard comparisons

- Cross-facility knowledge sharing

- Vendor and partner collaboration

- Technology upgrade evaluations

Future Trends in HOTO Logistics

Blockchain Technology

Immutable Handover Records: Blockchain technology offers potential for creating tamper-proof handover documentation, particularly valuable for:

- High-value asset transfers

- Regulatory compliance requirements

- Multi-party logistics operations

- International supply chain transitions

Augmented Reality (AR) Applications

Visual Handover Assistance: AR technology can enhance HOTO procedures by:

- Overlaying digital information on physical assets

- Providing step-by-step visual guidance for complex procedures

- Enabling remote expert assistance during handovers

- Creating immersive training experiences

Predictive Analytics

Proactive HOTO Management: Advanced analytics will enable:

- Prediction of optimal handover timing

- Identification of potential issues before they occur

- Resource optimization for transition periods

- Automated scheduling of handover activities

Data from the Supply Chain Management Review indicates that companies implementing predictive analytics in their handover processes see 42% reduction in transition-related incidents and 35% improvement in operational efficiency.

Building a Culture of HOTO Excellence

Leadership Commitment

Successful HOTO implementation requires strong leadership support:

- Executive sponsorship for procedure development and enforcement

- Resource allocation for training and technology investments

- Performance accountability at all organizational levels

- Continuous improvement mindset throughout the organization

Employee Engagement

Frontline Involvement:

- Include operational staff in procedure design

- Provide regular feedback on performance and improvements

- Recognize exceptional handover practices

- Create opportunities for peer-to-peer learning

Organizational Learning

Knowledge Management:

- Document lessons learned from handover experiences

- Share best practices across different operational units

- Maintain libraries of successful handover templates

- Invest in ongoing training and development programs

For organizations looking to optimize their HOTO processes, choosing the right warehouse management solution is crucial for successful implementation.

Conclusion: Maximizing Supply Chain Efficiency Through Effective HOTO

HOTO in logistics represents far more than just a procedural requirement – it’s a strategic advantage that separates high-performing supply chains from their competitors. Organizations that master handover takeover operations enjoy improved operational continuity, reduced risks, and enhanced customer satisfaction.

The key to successful HOTO implementation lies in balancing thoroughness with practicality. While comprehensive procedures are essential, they must be designed with real-world operational constraints in mind. Technology plays an increasingly important role, but it should enhance rather than complicate the fundamental goal of smooth transitions.

As supply chains become more complex and customer expectations continue to rise, the importance of effective HOTO procedures will only grow. Companies that invest in developing robust handover processes today will be better positioned to handle the challenges and opportunities of tomorrow’s logistics landscape.

Remember, HOTO logistics success isn’t measured by the complexity of your procedures, but by their effectiveness in maintaining operational excellence during transitions. Start with the basics, build on proven practices, and continuously refine your approach based on real-world results.

Modern businesses can benefit significantly from implementing comprehensive inventory management systems alongside HOTO procedures, while understanding WMS vs OMS considerations helps establish clear responsibilities. Additionally, automated inventory management solutions can further enhance handover accuracy and operational continuity.

Ready to optimize your logistics operations? Explore how modern technology solutions can streamline your HOTO procedures and enhance supply chain performance. Contact our logistics experts today to discover customized solutions for your specific operational needs.

Frequently Asked Questions (FAQs)

HOTO duration varies by complexity: simple shift changes take 15-30 minutes, equipment handovers require 30-60 minutes, facility transitions span several hours to days, and complete 3PL provider changes need 60-90 days.

Essential documents include operational status reports, safety and compliance records, performance metrics, asset condition assessments, and communication logs. A comprehensive checklist should cover verification steps, sign-offs, and escalation procedures.

Implementation follows five phases: assessment of transition points, development of standardized templates, technology integration, staff training, and performance monitoring. Benefits include improved continuity, reduced risks, enhanced accountability, and better compliance.

Main challenges include time constraints, communication barriers, staff resistance to change, documentation inconsistencies, and technology integration issues. Solutions include cloud-based platforms, mobile apps, automated systems, IoT integration, and AI-powered analytics.

Multiple stakeholders share responsibility: operations managers handle development and oversight, shift supervisors manage execution and training, quality teams oversee standardization, IT provides technology support, and frontline staff execute handovers. Performance is measured through completion rates, error frequencies, time efficiency, and compliance metrics.

Kapil Pathak is a Senior Digital Marketing Executive with over four years of experience specializing in the logistics and supply chain industry. His expertise spans digital strategy, search engine optimization (SEO), search engine marketing (SEM), and multi-channel campaign management. He has a proven track record of developing initiatives that increase brand visibility, generate qualified leads, and drive growth for D2C & B2B technology companies.