Here’s a number that should make every e-commerce business owner in India sit up: processing a single return costs up to 1.5 times more than the original forward delivery. Now multiply that by the millions of returns Indian e-commerce generates every single month, and you start to see why reverse logistics India has become one of the most critical operational challenges of our time.

India’s e-commerce market is booming. But with that growth comes a not-so-glamorous side effect: returns. Fashion brands deal with return rates of 30-35%. Electronics hover around 20%. And then there’s the uniquely Indian problem of COD rejections, where roughly 26% of cash-on-delivery orders never get accepted. That’s a lot of products traveling backward through the supply chain.

So, what’s the solution? Enter the Warehouse Management System (WMS) — a technology that’s quietly transforming how Indian businesses handle reverse logistics and returns management. If you’re new to the concept, our introduction to warehouse management is a great starting point.

In this article, we’ll break down exactly how WMS reverse logistics works, why it matters for Indian businesses, and how you can use it to turn your returns headache into a competitive advantage. Let’s dive in.

What Is Reverse Logistics, and Why Does It Matter in India?

Understanding the Reverse Supply Chain

Reverse logistics is essentially the journey a product takes after it’s been delivered — or attempted to be delivered — back through the supply chain. It includes everything from customer-initiated returns and RTO (Return to Origin) shipments to product recalls, refurbishment, and even e-waste recycling.

Unlike forward logistics, which follows a relatively predictable path from warehouse to customer, the reverse supply chain is messy. Products come back in varying conditions, from different locations, for different reasons. Some need restocking. Others need refurbishment. Some are destined for liquidation. And a few might just be fraudulent returns.

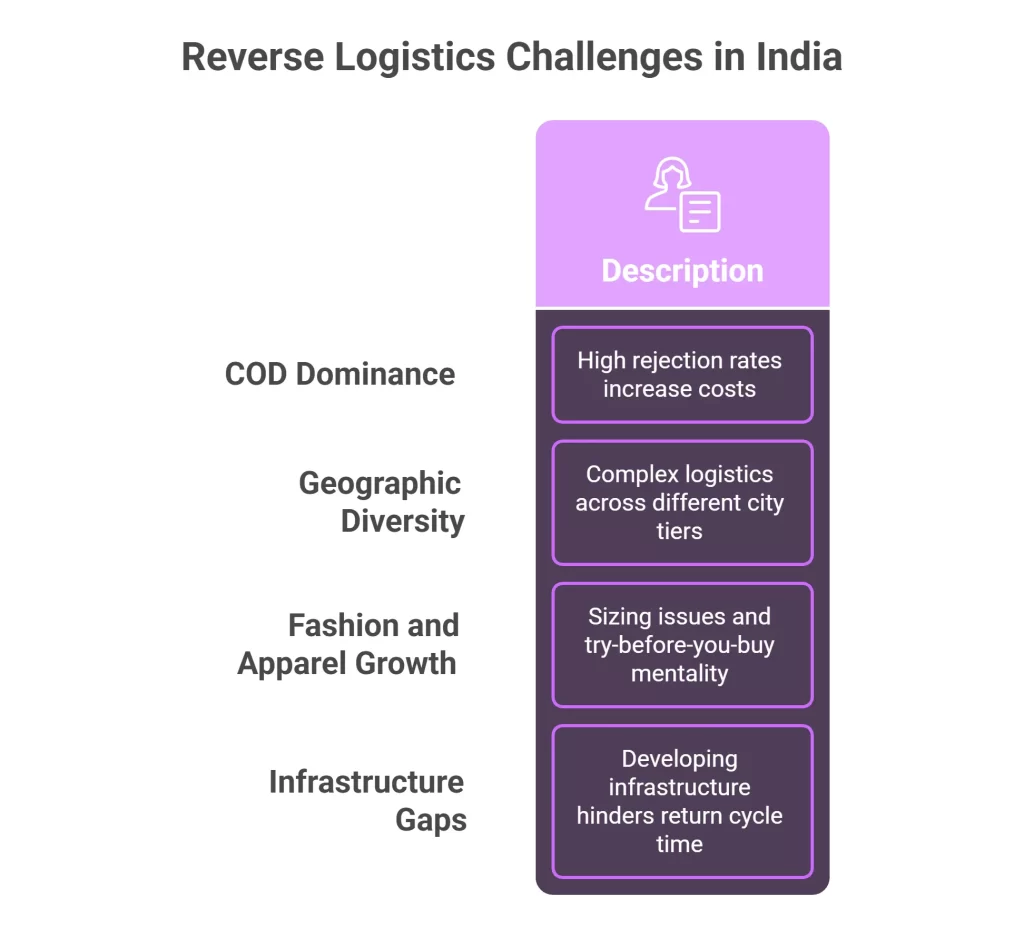

The Indian Context: Why It’s Uniquely Challenging

India’s reverse logistics market is estimated at \$50-90 billion and is growing at 7-20% CAGR through 2030-2033. Several factors make returns management in India particularly complex:

- COD dominance: Despite the growth of digital payments, cash on delivery remains popular. COD rejection management is a massive cost center because customers can simply refuse packages at the door.

- Geographic diversity: Managing reverse pickup logistics across tier-1, tier-2, and tier-3 cities requires sophisticated planning. Understanding supply chain visibility becomes critical in this context.

- Fashion and apparel growth: D2C returns logistics in fashion is especially challenging due to sizing issues and the “try before you buy” mentality.

- Infrastructure gaps: Unlike mature markets, India’s reverse logistics infrastructure is still developing, making return cycle time reduction harder to achieve.

Without a proper system in place, returns become a black hole that swallows profits. That’s where a returns management WMS comes in.

How WMS Transforms Returns Management in India

The Role of a Warehouse Management System in Returns

A warehouse management system returns module does something deceptively simple but incredibly powerful: it brings order to chaos. Instead of returns arriving at your warehouse and sitting in a pile waiting for someone to figure out what to do with them, a WMS creates automated, rule-based workflows that handle every step of the process.

Here’s what that looks like in practice:

- Return Merchandise Authorization (RMA): Before a product even ships back, the WMS generates an RMA and a Return ASN (Advance Shipping Notice), so the warehouse knows exactly what’s coming.

- Automated receiving and inspection: When the return arrives, warehouse staff use the WMS to log it, scan it, and trigger a quality grading workflow. Is the product in resalable condition? Does it need refurbishment? Is it damaged beyond repair? Efficient warehouse order picking and processing methods apply equally to returns handling.

- Condition-based binning: Based on the inspection results, the WMS automatically routes the product to the right location — restocking, refurbishment, liquidation, or disposal.

- Real-time inventory updates: The moment a returned item is processed, inventory levels update across all channels. This is critical for resale velocity optimization. Learn more about how inventory visibility impacts your bottom line.

- Returns analytics dashboard: Track everything from return rates by SKU to cost per return, disposition accuracy, and return-to-resale cycle time.

Cutting Return Processing Time by 40%

One of the most compelling benefits of WMS reverse logistics is speed. Automated workflows, predefined disposition rules, and real-time tracking can reduce return processing time by up to 40%. In a market where customers expect instant refund processing, that speed translates directly into customer satisfaction and repeat purchases.

Think about it this way: if a customer returns a shirt and gets their refund within 24 hours instead of 7 days, they’re far more likely to shop with you again. The WMS makes that possible by eliminating manual bottlenecks.

Key Features of Returns Management Software India Businesses Need

Automated Disposition Workflows

Not every returned product deserves the same treatment. A returns management system India businesses rely on should include disposition logic automation — rules that automatically determine what happens to each returned item based on its condition, category, age, and value.

For example:

- Grade A (like new): Restock immediately

- Grade B (minor defects): Route to refurbishment logistics

- Grade C (significant damage): Send to liquidation management

- Grade D (unsalvageable): Dispose or recycle per EPR compliance

This eliminates guesswork and ensures every product is handled in the most cost-effective way possible. If you’re struggling with common inventory management challenges, automated disposition is a strong first step.

Courier Integration and Reverse Pickup Management

In India, managing reverse logistics means working with multiple courier partners — Delhivery, Blue Dart, Ecom Express, and others. A good reverse logistics software India solution integrates directly with these carriers through a single platform, enabling:

- Automated reverse pickup scheduling

- Real-time returns tracking system visibility

- Courier performance analytics (RTO percentage by courier/region)

- Cost comparison across carriers for reverse shipments

This courier integration WMS capability is essential for third-party reverse logistics India operations and 3PL returns management providers. For deeper insights on courier tracking, check out our guide on last mile carrier tracking in India.

COD Returns and RTO Management

Let’s talk about the elephant in the room: RTO management India. Return to Origin shipments are one of the biggest cost drains in Indian e-commerce. When a customer refuses a COD order, the product travels all the way back to the seller, doubling the shipping cost with zero revenue.

A WMS helps tackle this problem in several ways:

- Predictive analytics: AI-powered return processing can flag high-risk orders before they ship, based on customer history, pin code data, and order patterns.

- Regional return hubs: By positioning returns hub management centers in major metros, businesses can reduce reverse transit from 7-8 days to 4-5 days.

- Faster restocking: The quicker a returned product gets back on the shelf, the less money you lose. Restocking automation through WMS makes this happen.

Returns Fraud Prevention

Return fraud is a growing concern in Indian e-commerce. From customers returning used products as new to sending back different items entirely, fraud eats into margins. A WMS with built-in return fraud prevention capabilities can:

- Flag serial number mismatches

- Track return patterns by customer

- Require photo documentation during inspection

- Enforce strict quality grading workflows

Building a Returns Processing Warehouse: Best Practices

Designing the Physical Space

Your returns processing warehouse needs a different layout than your forward fulfillment center. Here are the key zones to plan for:

- Return receiving areas: Dedicated docks and staging areas for incoming returns

- Inspection stations: Well-lit workstations with scanning equipment and photography setups

- Condition-based storage: Separate areas for resalable, refurbishment, and liquidation inventory

- Outbound restocking zone: For items cleared to go back into active inventory

Dealing with high return volumes? Our article on warehouse overflow challenges and solutions offers practical tips for managing space constraints.

Setting Up Regional Return Hubs

For businesses operating across India, a single centralized returns warehouse doesn’t cut it. Regional return hubs in cities like Mumbai, Delhi, Bangalore, and Kolkata can dramatically improve efficiency.

The math is straightforward: shorter reverse transit distances mean lower shipping costs, faster processing, and quicker inventory reconciliation returns. Many marketplace returns management operations now use a hub-and-spoke model where returns are first consolidated at regional hubs before being routed to their final destination.

Integrating WMS with OMS and Other Systems

A WMS doesn’t operate in isolation. For maximum impact, your WMS OMS integration returns setup should connect with:

- Order Management System (OMS): To link returns with original orders and trigger refunds. Understand the key differences in our WMS vs OMS in supply chain management guide.

- Returns portal automation: Customer-facing portals where shoppers initiate returns

- Marketplace integrations: For Shopify returns management WMS, Amazon returns logistics, and Flipkart reverse logistics

- Accounting systems: To track returns cost optimization and financial impact

This cloud-based returns management approach ensures data flows seamlessly across your entire operation.

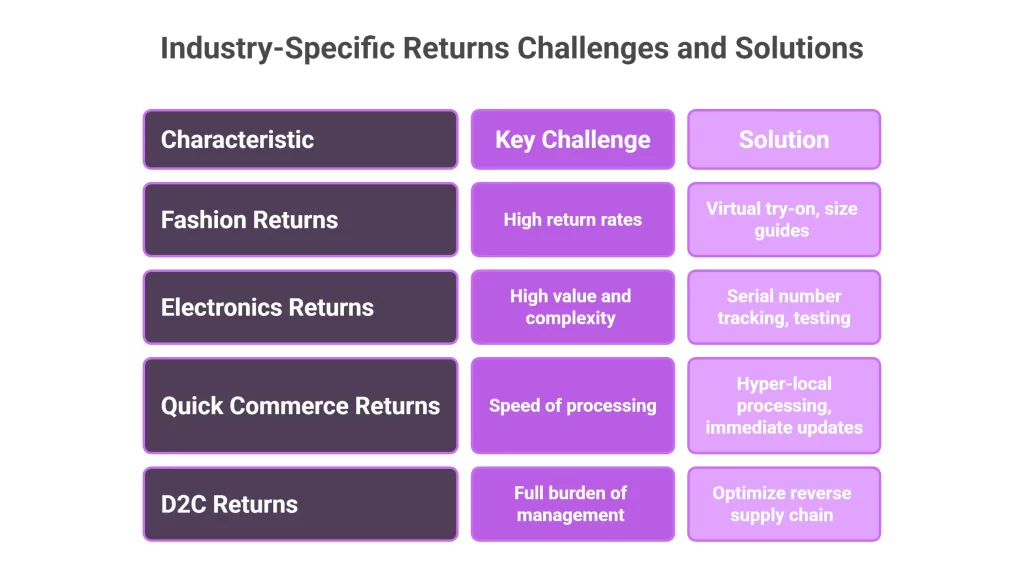

Industry-Specific Returns Challenges and Solutions

Fashion Returns Management

Fashion is the returns capital of Indian e-commerce. With return rates touching 30-35%, fashion returns management requires specialized approaches:

- Virtual try-on technology to reduce size-related returns

- Detailed size guides powered by returns data analytics

- Quick turnaround on returned inventory to catch seasonal demand

- Open-box resale management for items that can’t be sold as new

Electronics Returns Processing

Electronics present unique challenges because of their higher value and complexity. Processing these high-value returns through WMS involves:

- Serial number tracking and verification

- Functional testing workflows

- Certified refurbished products programs

- E-waste reverse logistics compliance under Extended Producer Responsibility (EPR) regulations

Quick Commerce Returns

The rise of quick commerce in India adds another layer of complexity. Quick commerce returns need to be processed in hours, not days. WMS solutions for this segment focus on hyper-local returns processing and immediate inventory updates.

D2C Returns Logistics

Direct-to-consumer brands face the full burden of returns management without marketplace support. D2C returns logistics powered by WMS helps these brands maintain profitability by optimizing every step of the reverse supply chain.

Reverse Logistics KPIs Every Indian Business Should Track

You can’t improve what you don’t measure. Here are the essential reverse logistics KPIs to monitor through your WMS:

| KPI | What It Measures | Target Benchmark |

|---|---|---|

| RTO % by courier/region | Carrier and geographic performance | Below 20% |

| Return-to-resale cycle time | Speed of getting returns back on shelf | Under 5 days |

| Disposition accuracy | Correct routing of returned items | Above 95% |

| Cost per return | Total processing cost per unit | Continuously decreasing |

| Recovery value rate | Revenue recovered from returns | Above 60% |

| Return fraud rate | Percentage of fraudulent returns | Below 2% |

| Customer satisfaction (returns) | NPS score for returns experience | Above 70 |

Tracking these metrics through a returns analytics dashboard gives you the visibility needed for continuous improvement and returns cost optimization. For a broader look at inventory metrics, explore our guide on inventory turnover ratio.

The Future of Reverse Logistics in India

AI and Automation

The next wave of innovation in reverse logistics software India is being driven by artificial intelligence. AI-powered return processing can predict which orders are likely to be returned before they’re even shipped, enabling proactive measures like order verification calls for high-risk COD shipments.

Machine learning algorithms are also improving disposition logic automation, learning from thousands of past returns to make increasingly accurate grading decisions.

Sustainability and Circular Economy

With growing awareness around sustainability, sustainable returns management is becoming a business imperative. The circular economy logistics India movement is pushing businesses to:

- Maximize product recovery and refurbishment

- Develop pre-owned goods refurbishment programs

- Create certified refurbished products marketplaces

- Comply with Extended Producer Responsibility (EPR) regulations for electronics, packaging, and batteries

Cloud-Based Returns Management Platforms

The shift toward returns management platforms that are cloud-native, API-first, and designed for the Indian market is accelerating. These platforms combine WMS capabilities with returns portal automation, courier integration, and advanced analytics in a single solution.

Conclusion

Reverse logistics and returns management don’t have to be a cost center that drains your profits. With the right WMS returns India strategy, you can transform returns into a source of competitive advantage — recovering more value from returned products, delighting customers with fast refunds, and gaining insights that help reduce return rates over time.

The Indian e-commerce landscape is only going to get more competitive. Businesses that invest in automated returns management today will be the ones that thrive tomorrow. Whether you’re a D2C brand, a marketplace seller, or a 3PL provider, the message is clear: get your reverse logistics right, or watch your margins disappear.

Ready to take control of your returns? Start by evaluating your current returns process, identifying the biggest pain points, and exploring WMS solutions that are built for the Indian market. The technology exists. The ROI is proven. The only question is: how soon will you act?

Why OmneeLabWMS Is the Smart Choice for Reverse Logistics in India

If you’re looking for a WMS that’s purpose-built for Indian businesses, OmneeLabWMS deserves your attention. With features like automated disposition workflows, multi-courier integration, real-time inventory reconciliation, and a powerful returns analytics dashboard, OmneeLabWMS helps e-commerce brands, D2C sellers, and 3PL providers streamline their entire reverse logistics operation. From COD rejection management to regional return hub coordination, it’s designed to handle the unique complexities of the Indian market.

Stop Losing Money on Returns. Let OmneeLabWMS Fix That.

Every day you operate without a proper returns management system, you’re leaving money on the table. OmneeLabWMS gives you the tools to reduce return processing time, cut RTO costs, prevent fraud, and recover maximum value from every returned product. Whether you’re processing 100 returns a day or 10,000, OmneeLabWMS scales with your business. Book a free demo today and see the difference a smart WMS makes.

Frequently Asked Questions (FAQs)

Reverse logistics covers the entire process of moving products from customers back through the supply chain. A WMS automates this with RMA generation, quality grading workflows, condition-based binning, and disposition logic to route items for restocking, refurbishment, or disposal.

A WMS uses automated workflows, predefined disposition rules, and real-time tracking to eliminate manual sorting and decision-making. This can reduce return processing time by up to 40%, enabling faster refunds and quicker restocking.

RTO (Return to Origin) happens when COD orders are rejected at delivery. A WMS helps by flagging high-risk orders using predictive analytics, optimizing reverse pickup routes, and enabling faster restocking through regional return hubs.

Regional hubs in major metros like Delhi, Mumbai, and Bangalore reduce reverse transit from 7-8 days to 4-5 days. A WMS coordinates inventory across hubs, optimizes disposition decisions locally, and provides centralized visibility.

EPR is a regulatory framework requiring producers to manage end-of-life disposal of electronics, batteries, and packaging. A WMS tracks returned products through the entire reverse chain, documenting proper handling for compliance reporting.

Kapil Pathak is a Senior Digital Marketing Executive with over four years of experience specializing in the logistics and supply chain industry. His expertise spans digital strategy, search engine optimization (SEO), search engine marketing (SEM), and multi-channel campaign management. He has a proven track record of developing initiatives that increase brand visibility, generate qualified leads, and drive growth for D2C & B2B technology companies.