In today’s fast-paced, customer-driven economy, inventory visibility has become a cornerstone of successful supply chain management. As businesses strive to meet rising consumer expectations, keeping track of inventory in real-time across multiple channels has never been more critical. But as the landscape evolves, the Future of Inventory Visibility brings new challenges and opportunities for businesses to explore.

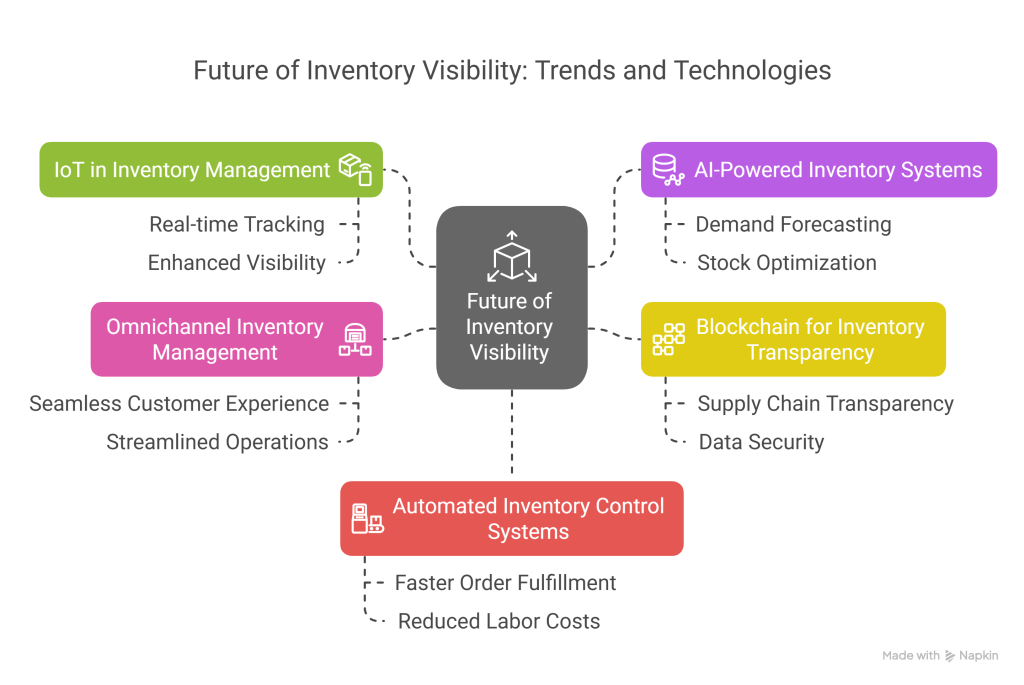

By 2025, inventory visibility will be shaped by emerging technologies such as IoT, AI, and blockchain, alongside growing demands for supply chain transparency and real-time inventory tracking. In this article, we’ll dive into the Inventory Management Trends defining 2025, the challenges businesses are likely to encounter, and actionable strategies to overcome inventory visibility challenges.

Why Inventory Visibility Matters More Than Ever

Inventory visibility refers to the ability to track the location, quantity, and status of inventory across the supply chain in real-time. For businesses, it’s not just about knowing what’s in stock—it’s about understanding where that stock is, how quickly it’s moving, and what’s needed to meet demand efficiently.

In 2025, inventory visibility will be at the heart of operational success for several reasons:

- E-commerce Growth: The explosion of e-commerce has increased the complexity of inventory management, with businesses needing to manage stock across warehouses, retail outlets, and online marketplaces.

- Customer Expectations: Consumers now expect fast, accurate order fulfillment, making real-time inventory tracking essential for meeting delivery promises.

- Global Supply Chains: As supply chains become more globalized, having a clear view of inventory at all stages is critical for minimizing disruptions.

Key Trends Shaping Inventory Visibility in 2025

The Future of Inventory Visibility is being shaped by technological advancements and changing market dynamics. Let’s explore the key Inventory Management Trends businesses need to watch.

1. IoT in Inventory Management

The Internet of Things (IoT) is revolutionizing inventory visibility by enabling real-time tracking of goods. IoT-powered devices such as RFID tags and smart sensors provide businesses with accurate, up-to-the-minute data on inventory movement, location, and condition.

- Example: A warehouse manager can use IoT sensors to track products’ temperature during transit, ensuring compliance with quality standards.

- Benefit: Enhanced visibility minimizes losses, improves decision-making, and strengthens supply chain transparency.

2. AI-Powered Inventory Systems

Artificial intelligence (AI) is becoming a cornerstone of advanced inventory management systems. AI enables businesses to analyze vast amounts of data for better demand forecasting, stock level optimization, and predictive maintenance.

- Example: AI algorithms can predict seasonal demand spikes, helping retailers stock the right products at the right time.

- Benefit: Reduced overstocking and understocking, resulting in cost savings and improved efficiency.

3. Blockchain for Inventory Transparency

Blockchain is gaining traction as a tool for enhancing supply chain transparency. By creating a decentralized ledger, blockchain ensures that all stakeholders have access to accurate, tamper-proof data about inventory movement.

- Example: A blockchain-based system can track a product’s journey from manufacturer to retailer, ensuring authenticity and ethical sourcing.

- Benefit: Increased trust and accountability in supply chains.

4. Omnichannel Inventory Management

As businesses expand across multiple sales channels, omnichannel inventory management becomes crucial. This approach integrates inventory data from all channels (e.g., online stores, physical outlets) into a single system, ensuring seamless stock management.

- Example: Customers can order online and pick up in-store if businesses have accurate visibility of stock across locations.

- Benefit: Improved customer experience and streamlined operations.

5. Automated Inventory Control Systems

Automation is at the core of smart inventory solutions. Automated systems such as AS/RS (Automated Storage and Retrieval Systems) and robotics reduce manual labor, improve accuracy, and enhance efficiency.

- Example: A robotic system can retrieve products from a warehouse shelf and prepare them for shipment in seconds.

- Benefit: Faster order fulfillment and reduced labor costs.

Challenges to Inventory Visibility in 2025

Despite these advancements, businesses still face several challenges in achieving real-time inventory tracking and visibility.

1. Data Silos

One of the biggest barriers to inventory visibility is fragmented data. When inventory data is stored across disconnected systems, it becomes difficult to get a clear, unified view of stock levels.

2. Supply Chain Disruptions

Global events such as pandemics, natural disasters, and geopolitical tensions can disrupt supply chains, making it harder to track inventory and ensure timely deliveries.

3. Cybersecurity Risks

With the increasing digitalization of inventory management, the risk of cyberattacks grows. Businesses must ensure that their systems are secure to protect sensitive inventory data.

4. Lack of Skilled Workforce

Implementing and managing advanced inventory management systems requires skilled personnel. A lack of trained professionals can hinder the adoption of new technologies.

How to Overcome Inventory Visibility Challenges

To overcome these challenges and stay ahead of the competition, businesses need to adopt proactive strategies. Here’s how:

1. Invest in Advanced Technology

Leverage technologies such as IoT, AI, and blockchain to enhance inventory visibility. These tools provide real-time data, predictive insights, and greater transparency.

2. Embrace Warehouse Digitization

Digitizing your warehouse operations can significantly improve inventory tracking. Use smart sensors, RFID technologies, and cloud computing in warehouse management to streamline processes.

3. Implement a Unified Inventory System

Replace fragmented systems with a single, integrated platform. An advanced warehouse management system can consolidate data from multiple sources, giving you a unified view of inventory.

4. Focus on Employee Training

Train your workforce to use new technologies effectively. Skilled employees can maximize the benefits of automation and digitalization, ensuring smooth operations.

5. Prioritize Cybersecurity

Implement robust cybersecurity measures to protect your inventory systems from threats. Regular audits, firewalls, and encryption can help safeguard your data.

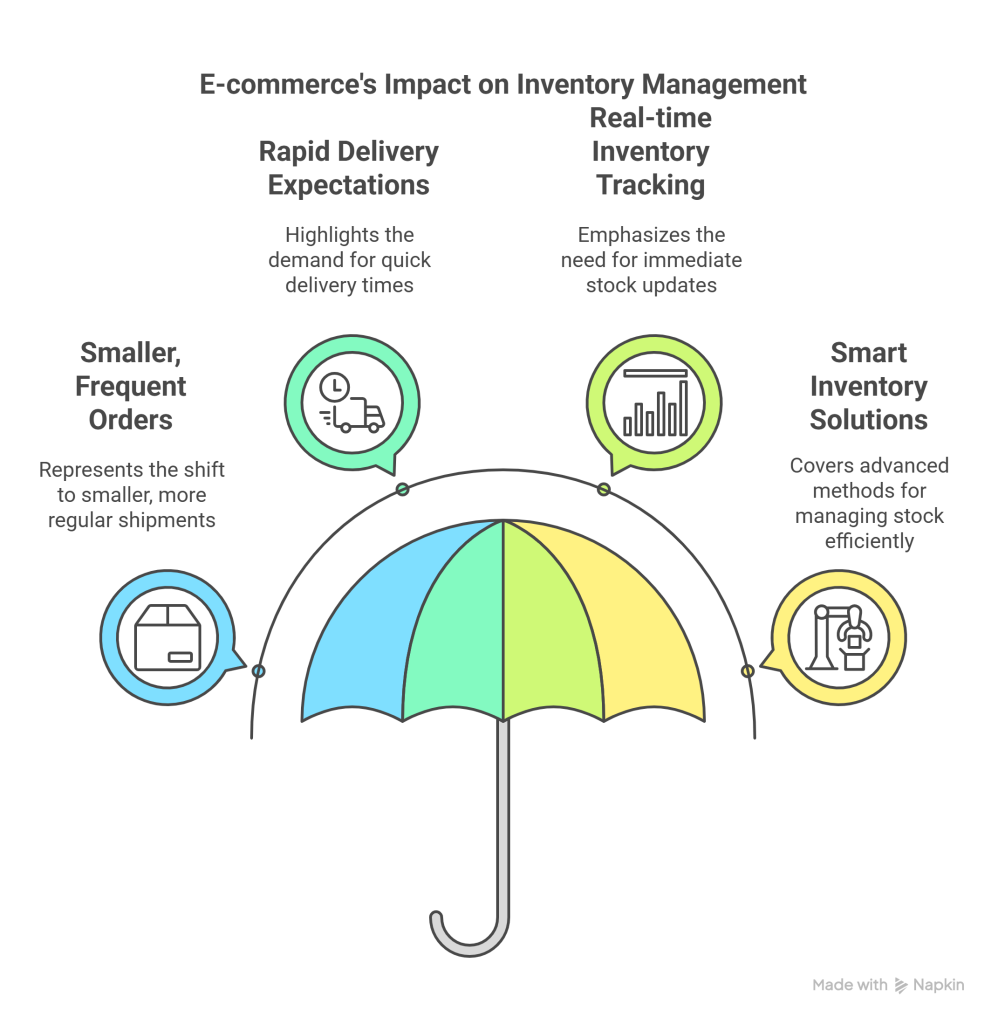

The Role of E-commerce in Shaping Inventory Visibility

E-commerce has revolutionized the way businesses manage inventory. With the rise of online shopping, businesses must adapt to new challenges such as:

- Smaller, frequent orders: Unlike traditional bulk shipments, e-commerce involves processing smaller, more frequent orders.

- Rapid delivery expectations: Customers now expect same-day or next-day delivery, making real-time inventory tracking essential.

To meet these demands, businesses are turning to smart inventory solutions such as cross-channel inventory integration and automated order fulfillment.

The Future of Inventory Visibility: What Lies Ahead

Looking ahead to 2025, the future of inventory visibility will be defined by innovation, collaboration, and a focus on customer-centric solutions. Here’s what we can expect:

- Increased Adoption of AI and IoT: AI and IoT will become standard in inventory management, enabling businesses to predict demand, track inventory in real-time, and optimize stock levels.

- Expansion of Blockchain: Blockchain technology will play a key role in ensuring inventory transparency and traceability across the supply chain.

- Greater Focus on Sustainability: Businesses will use inventory visibility tools to minimize waste, reduce carbon footprints, and promote sustainable practices.

- Rise of Autonomous Warehouses: Fully automated warehouses equipped with robotics and AS/RS will become more common, driving efficiency and accuracy.

Conclusion: Embrace Innovation for Better Inventory Visibility

The Inventory Visibility 2025 landscape is full of exciting opportunities for businesses that are willing to embrace change. By leveraging real-time inventory tracking, adopting advanced inventory management systems, and overcoming challenges with proactive strategies, businesses can achieve seamless operations and enhanced customer satisfaction.

Ready to take your inventory management to the next level? Explore how AI and other cutting-edge technologies can help your business conquer inventory challenges and thrive in the future.

FAQs: Inventory Visibility 2025

Inventory visibility is the ability to track and monitor stock in real-time across the supply chain. It’s important because it ensures accurate inventory levels, prevents stockouts or overstocking, improves customer satisfaction, and enhances operational efficiency.

The key trends include the adoption of IoT for real-time tracking, AI-powered inventory systems for demand forecasting, blockchain for supply chain transparency, omnichannel inventory management, and warehouse digitization.

IoT enables real-time tracking of inventory through smart sensors and RFID technologies. It provides accurate data on stock levels, product location, and storage conditions, helping businesses make informed decisions and streamline operations.

The main challenges include fragmented data across systems, supply chain disruptions, cybersecurity threats, high implementation costs for advanced technologies, and a lack of skilled workforce to manage new systems.

Businesses can overcome these challenges by investing in advanced technologies like AI, IoT, and blockchain, digitizing warehouse operations, implementing unified inventory systems, prioritizing cybersecurity, and training employees to use modern tools effectively.

Kapil Pathak is a Senior Digital Marketing Executive with over four years of experience specializing in the logistics and supply chain industry. His expertise spans digital strategy, search engine optimization (SEO), search engine marketing (SEM), and multi-channel campaign management. He has a proven track record of developing initiatives that increase brand visibility, generate qualified leads, and drive growth for D2C & B2B technology companies.