Running a business without proper inventory control is like driving blindfolded – you might get lucky for a while, but eventually, you’re heading for trouble. Whether you’re managing a small retail shop or overseeing warehouse operations for a major corporation, inventory management challenges can make or break your bottom line.

The numbers don’t lie: poor inventory management costs businesses billions annually through stockouts, excess inventory, and operational inefficiencies. But here’s the good news – most inventory management problems have proven solutions that successful companies use every day.

In this comprehensive guide, we’ll explore the 12 most common inventory management challenges that businesses face and provide actionable inventory management solutions to help you optimize your operations, reduce costs, and improve customer satisfaction.

Why Inventory Management Matters More Than Ever

Before diving into specific challenges, let’s understand why getting inventory right is crucial. Modern consumers expect products available instantly, whether they’re shopping online or in-store. Meanwhile, carrying excess inventory ties up valuable capital and increases storage costs. This delicate balance between having enough stock without overcommitting resources is what makes inventory management both challenging and critical.

Poor inventory management affects businesses through:

- Lost sales from stockouts

- Increased carrying costs from excess inventory

- Reduced cash flow

- Customer dissatisfaction

- Operational inefficiencies

Now, let’s examine the specific challenges and their solutions.

Challenge 1: Inaccurate Demand Forecasting

The Problem: Predicting customer demand feels like reading tea leaves sometimes. Traditional forecasting methods often rely on historical data that doesn’t account for market shifts, seasonal variations, or unexpected events. This leads to either stockouts during high-demand periods or excess inventory during slow seasons.

Demand forecasting accuracy directly impacts your ability to maintain optimal stock levels. Many businesses struggle with this because they’re using outdated methods or insufficient data points.

The Solution: Modern demand planning challenges require sophisticated approaches:

- Implement AI-powered forecasting tools that analyze multiple data sources including sales history, market trends, and external factors

- Use ABC inventory analysis to prioritize forecasting efforts on high-value items

- Incorporate real-time data from multiple channels to adjust forecasts dynamically

- Collaborate with sales teams to gather insights about upcoming promotions or market changes

- Track forecast accuracy and continuously refine your models

For businesses looking to implement advanced forecasting, consider exploring demand-driven replenishment strategies that can significantly improve your prediction accuracy and reduce inventory holding costs.

Best Practice: Start with your top 20% of products (by revenue) and gradually expand your sophisticated forecasting to other items. This approach maximizes impact while managing complexity.

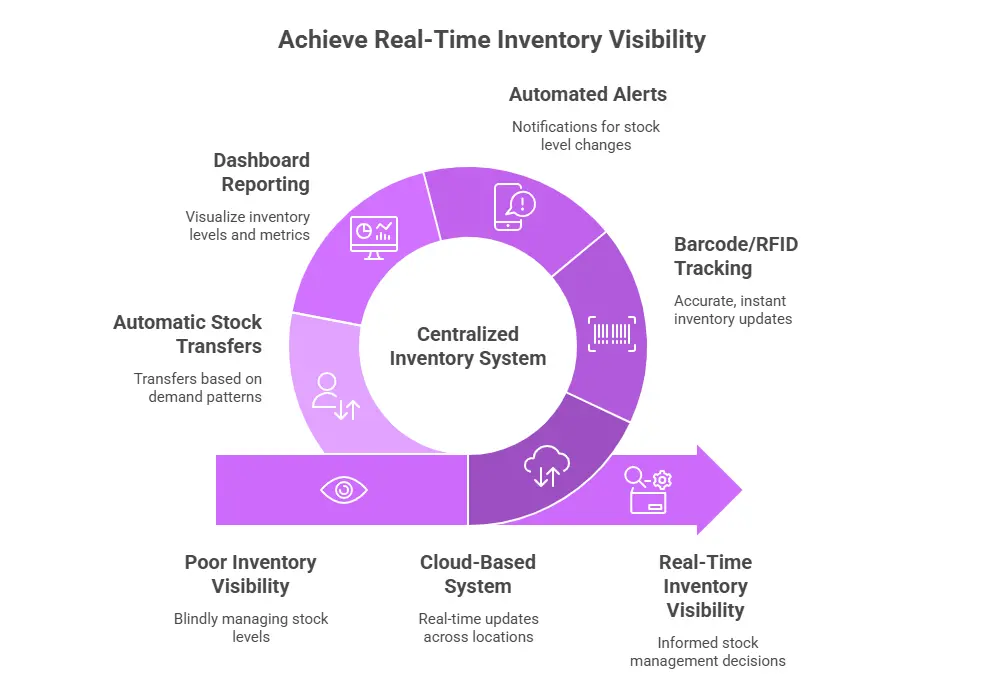

Challenge 2: Poor Inventory Visibility Across Locations

The Problem: If you can’t see your inventory in real-time across all locations, you’re essentially flying blind. This lack of real-time inventory visibility leads to situations where you’re overstocked in one location while experiencing stockouts in another.

Multi-location inventory management becomes exponentially more complex as businesses grow. Without proper systems, coordinating stock between warehouses, retail stores, and distribution centers becomes a nightmare.

The Solution: Inventory management software with centralized visibility is essential:

- Deploy a cloud-based inventory system that provides real-time updates across all locations

- Implement barcode inventory tracking or RFID inventory solutions for accurate, instant updates

- Create automated alerts for low stock levels, overstock situations, and transfer opportunities

- Use dashboard reporting to visualize inventory levels, turnover rates, and performance metrics

- Enable automatic stock transfers between locations based on demand patterns

Pro Tip: Choose an inventory management platform that integrates with your existing systems (POS, e-commerce, accounting) to avoid data silos.

Challenge 3: Stockouts and Overstock Situations

The Problem: Finding the sweet spot between having enough inventory and not tying up too much capital is one of the most persistent inventory control problems. Stockouts frustrate customers and lose sales, while overstock increases carrying costs and risks obsolescence.

Stockout prevention and excess inventory reduction require careful balance and ongoing attention.

The Solution: Stock level optimization through systematic approaches:

- Calculate optimal reorder points based on lead times, demand variability, and service level targets

- Implement safety stock calculation methods that account for demand and supply uncertainty

- Use inventory turnover ratio analysis to identify slow-moving items

- Set up automated reordering for fast-moving products with predictable demand

- Regular inventory reconciliation to ensure system accuracy matches physical counts

Action Item: Review your inventory turnover ratio monthly. Items with ratios below industry benchmarks may indicate overstock situations requiring attention.

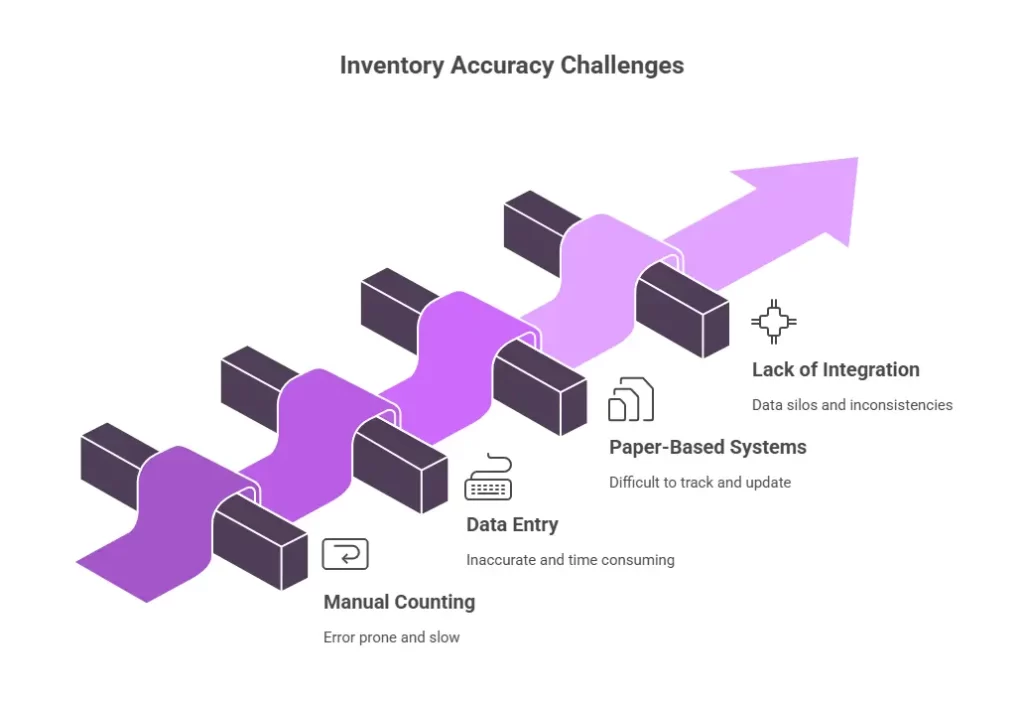

Challenge 4: Manual Processes and Human Error

The Problem: Relying on manual processes for inventory management is like asking for trouble. Human errors in counting, data entry, and record-keeping compound over time, leading to significant inventory accuracy problems.

Inventory tracking challenges multiply when processes depend heavily on manual intervention, spreadsheets, and paper-based systems.

The Solution: Automated inventory control systems reduce errors and improve efficiency:

- Replace manual counting with barcode inventory tracking or RFID systems

- Automate data entry through integration between systems

- Implement cycle counting procedures instead of relying solely on annual physical counts

- Use mobile devices with scanning capabilities for real-time updates

- Create standardized processes with clear procedures and accountability

Learn more about manual and automated inventory management differences and how automation can transform your operations. For small businesses, implementing small business barcoding solutions can be a cost-effective first step toward automation.

Reality Check: Even small improvements in accuracy can have significant impacts. Improving inventory accuracy from 85% to 95% can reduce safety stock requirements by 20-30%.

Challenge 5: Inadequate Technology Infrastructure

The Problem: Many businesses outgrow their initial inventory systems but continue using outdated technology that can’t scale with their needs. Spreadsheets, basic software, or disconnected systems create bottlenecks and limit growth potential.

Warehouse management challenges often stem from technology limitations that prevent efficient operations.

The Solution: Invest in scalable inventory management solutions:

- Evaluate your current technology against your business requirements

- Choose a warehouse management system (WMS) that integrates with your other business systems

- Prioritize cloud-based solutions for scalability and accessibility

- Ensure mobile compatibility for warehouse and field operations

- Plan for integration with e-commerce platforms, accounting systems, and other tools

OmneelabWMS offers comprehensive warehouse management solutions that scale with your business. Whether you’re selling on Shopify, WooCommerce, Magento, or other platforms, their integrated approach ensures seamless operations across all channels.

Investment Perspective: While technology upgrades require upfront investment, the ROI from improved efficiency, accuracy, and reduced labor costs typically pays for itself within 12-18 months.

Challenge 6: Lack of Real-Time Data and Analytics

The Problem: Making inventory decisions based on outdated information is like navigating with an old map. Without real-time data and analytics, you’re always reacting to problems rather than preventing them.

Supply chain inventory issues often arise from delayed information and poor visibility into trends and patterns.

The Solution: Implement comprehensive analytics and reporting:

- Deploy real-time dashboards showing key inventory metrics

- Track leading indicators like order trends, seasonal patterns, and supplier performance

- Use predictive analytics to anticipate problems before they occur

- Create automated reports for different stakeholders (operations, finance, management)

- Monitor key performance indicators like fill rates, inventory turns, and carrying costs

Understanding why visibility in supply chain is important can help you appreciate the value of real-time data. Modern WMS solutions provide comprehensive analytics that transform raw data into actionable insights.

Metric Focus: Track these essential KPIs weekly: inventory turnover, stockout frequency, forecast accuracy, and carrying cost percentage.

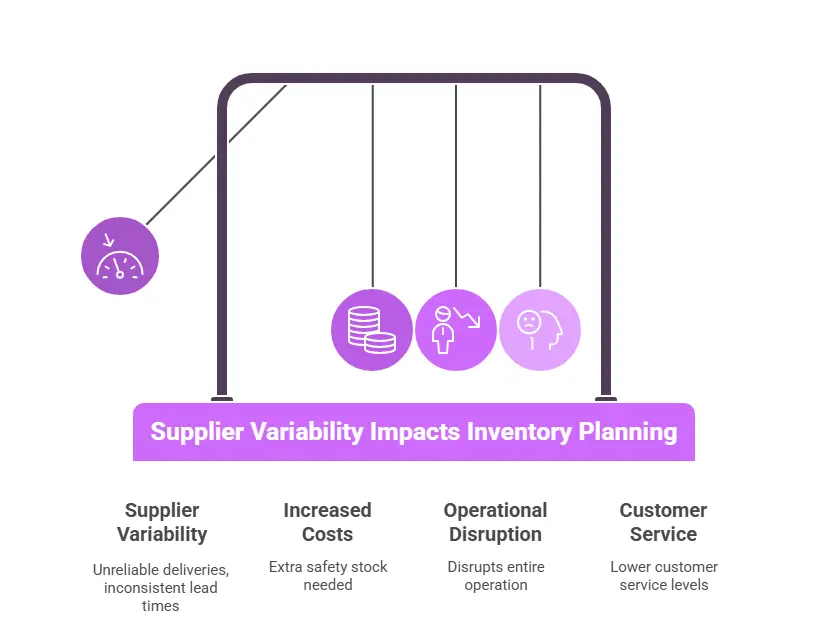

Challenge 7: Supplier and Lead Time Variability

The Problem: Unreliable suppliers and inconsistent lead times make inventory planning extremely difficult. When you can’t count on deliveries arriving on time, you’re forced to carry extra safety stock, increasing costs and complexity.

Supply chain inventory issues from supplier variability can disrupt your entire operation and customer service levels.

The Solution: Build supplier reliability and manage variability:

- Diversify your supplier base to reduce dependency on single sources

- Track supplier performance metrics including on-time delivery, quality, and communication

- Build stronger relationships with key suppliers through regular communication and partnerships

- Negotiate better terms including guaranteed lead times and quality standards

- Implement supplier scorecards and regular performance reviews

Learn about buffer stock calculation and optimization to manage supplier variability effectively. Proper buffer stock management can protect your operations from supply chain disruptions.

Risk Management: Identify your critical suppliers and develop contingency plans. Having backup suppliers for essential items can save you from major disruptions.

Challenge 8: Seasonal and Promotional Planning

The Problem: Seasonal inventory planning requires predicting demand spikes and valleys months in advance. Promotions, holidays, and seasonal trends can dramatically impact inventory needs, but many businesses struggle to plan effectively for these variations.

Retail inventory management problems often center around seasonal misalignment and promotional inventory challenges.

The Solution: Develop sophisticated seasonal and promotional planning:

- Analyze historical seasonal patterns but adjust for market changes

- Coordinate with marketing teams on promotional calendars and expected impacts

- Plan inventory buildup and drawdown schedules for seasonal items

- Use flexible supplier agreements that allow for volume adjustments

- Monitor competitor activities and market trends that might affect demand

For fashion and seasonal businesses, implementing seasonal inventory management strategies can make the difference between profitable seasons and costly overstock situations.

Planning Tip: Start seasonal planning 4-6 months in advance, and create multiple scenarios (conservative, expected, optimistic) to guide your decisions.

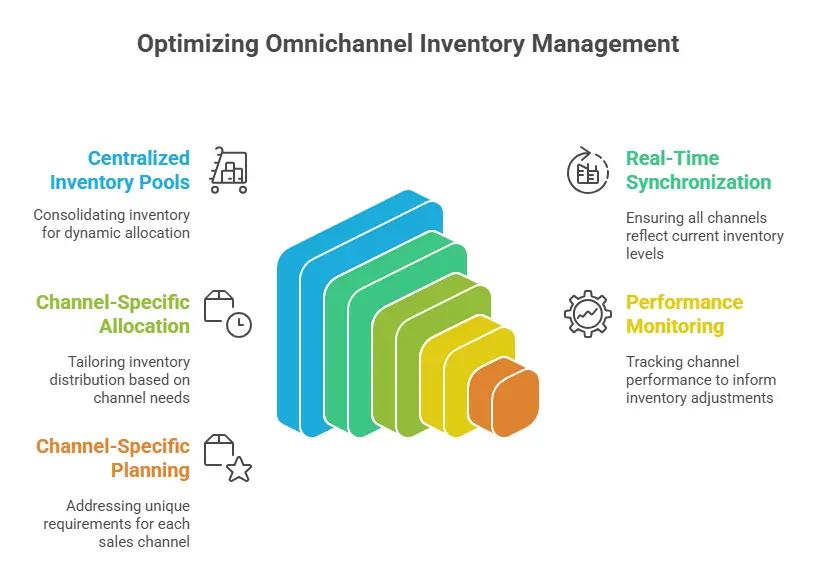

Challenge 9: Managing Multiple Sales Channels

The Problem: Omnichannel inventory sync becomes complex when selling through multiple channels – retail stores, e-commerce platforms, marketplaces, and wholesale. Without proper coordination, you risk overselling on one channel while having excess inventory in another.

E-commerce inventory management adds layers of complexity, especially when integrating with physical retail operations.

The Solution: Implement unified inventory management across channels:

- Use centralized inventory pools that can be allocated across channels dynamically

- Implement real-time synchronization between all sales channels

- Set channel-specific allocation rules based on performance and priorities

- Monitor channel performance and adjust inventory distribution accordingly

- Plan for channel-specific requirements like packaging, shipping, and handling

OmneelabWMS excels in multi-channel integration, supporting major Indian marketplaces including Myntra, Meesho, JioMart, Ajio, Snapdeal, Nykaa, and Tata Cliq. This comprehensive integration ensures consistent inventory across all your sales channels.

Integration Focus: Ensure your inventory system can handle the complexity of modern retail, including buy-online-pickup-in-store (BOPIS) and ship-from-store capabilities.

Challenge 10: Cost Control and Carrying Expenses

The Problem: Inventory carrying costs include storage, insurance, taxes, obsolescence, and opportunity costs of tied-up capital. Many businesses don’t fully understand these costs or factor them into inventory decisions, leading to suboptimal stocking strategies.

Inventory cost reduction requires balancing service levels with financial efficiency.

The Solution: Implement cost-conscious inventory management:

- Calculate true carrying costs including all direct and indirect expenses

- Use economic order quantity (EOQ) models for optimal order sizing

- Implement ABC analysis to focus efforts on high-impact items

- Regular review of slow-moving inventory and implement clearance strategies

- Negotiate better payment terms with suppliers to improve cash flow

Understanding different types of inventory replenishment can help you choose the most cost-effective approach for different product categories.

Financial Impact: Reducing inventory levels by just 10% while maintaining service levels can free up significant cash for other business investments.

Challenge 11: Quality Control and Product Returns

The Problem: Inventory shrinkage control isn’t just about theft – it includes damage, obsolescence, and quality issues. Returns and defective products create additional complexity in inventory management and can significantly impact profitability.

Dead stock management becomes critical when quality issues or returns create unsellable inventory.

The Solution: Implement comprehensive quality and returns management:

- Establish quality control procedures at receiving and throughout storage

- Create efficient returns processing workflows

- Track return reasons and work with suppliers to address root causes

- Implement proper storage conditions to minimize damage and deterioration

- Develop liquidation strategies for damaged or returned items

Learn more about inventory shrinkage and top 7 ways to prevent it to protect your inventory investment. For businesses dealing with perishable goods, managing perishable inventory requires specialized approaches.

Process Improvement: Create clear procedures for handling returns, including inspection, restocking decisions, and disposal of unsellable items.

Challenge 12: Scalability and Growth Management

The Problem: Systems and processes that work for a small business often break down as companies grow. Small business inventory issues can become enterprise inventory solutions challenges without proper planning and system evolution.

Warehouse management challenges multiply as volume increases and complexity grows.

The Solution: Build scalable inventory management capabilities:

- Choose scalable technology platforms that can grow with your business

- Develop standardized processes that can be replicated across locations

- Invest in training and development for your inventory management team

- Plan for increased complexity in product lines, locations, and channels

- Regular system and process reviews to identify bottlenecks and improvement opportunities

Growth Strategy: Build flexibility into your systems and processes from the beginning. It’s easier to scale up robust systems than to replace inadequate ones later.

The Power of Integrated WMS and Last-Mile Delivery Solutions

One of the most significant advances in solving inventory management challenges is the integration of warehouse management systems with last-mile delivery solutions. This integration addresses multiple challenges simultaneously:

Unified Operations:

- Real-time inventory updates from warehouse to delivery

- Automated order routing based on inventory location

- Reduced fulfillment times and improved customer satisfaction

Enhanced Visibility:

- Track products from storage to customer doorstep

- Predictive delivery scheduling based on inventory availability

- Proactive customer communication about order status

Cost Optimization:

- Optimize delivery routes based on inventory locations

- Reduce shipping costs through intelligent fulfillment center selection

- Minimize returns through better inventory accuracy

Omneelab Technologies offers comprehensive last mile SaaS specifically designed for the Indian market. This integration helps businesses optimize last-mile delivery stations while maintaining perfect inventory synchronization.

Best Practices for Overcoming Inventory Management Challenges

Successfully addressing inventory management challenges requires a systematic approach combining technology, processes, and people:Technology Foundation:

- Invest in integrated inventory management software like OmneelabWMS

- Ensure real-time visibility across all locations and channels

- Use automation to reduce manual errors and improve efficiency

- Implement barcode technology for inventory management or QR codes for warehouse management

Process Excellence:

- Implement standardized procedures for all inventory activities

- Create comprehensive SOPs for inventory management

- Regular training and updates for staff

- Continuous improvement mindset with regular reviews and optimizations

Performance Management:

- Track key metrics and KPIs consistently

- Use data-driven decision making

- Regular supplier and process performance reviews

- Implement mastering inventory audits procedures

Strategic Planning:

- Align inventory strategy with business objectives

- Plan for growth and scalability

- Consider total cost of ownership, not just purchase prices

- Understand future warehouse management trends for 2025

Industry-Specific Solutions

Different industries face unique inventory management challenges:E-commerce and Retail:

- Multi-channel inventory synchronization

- Seasonal demand fluctuations

- Returns management

- Fast-moving consumer goods tracking

Manufacturing:

- Raw material planning

- Work-in-progress tracking

- Bill of materials management

- Production scheduling integration

Pharmaceuticals:

- Batch and expiry tracking in FMCG

- Regulatory compliance

- Temperature-controlled storage

- Serialization requirements

3PL and Logistics:

- Multi-client inventory management

- Complex billing and reporting

- Scalable operations

- Avoiding common 3PL WMS mistakes

The Cost of Ignoring Inventory Management Problems

Businesses that don’t address common inventory management issues face significant consequences:

- Lost sales from stockouts can cost 3-5% of annual revenue

- Excess inventory typically costs 20-30% annually in carrying costs

- Poor inventory accuracy leads to operational inefficiencies and customer dissatisfaction

- Manual processes create labor costs and error rates that compound over time

The good news? Most of these problems have proven solutions that successful companies use every day.

Conclusion: Taking Action on Your Inventory Challenges

Inventory management challenges are universal, but they’re not insurmountable. The key is recognizing which challenges affect your business most significantly and implementing systematic solutions.

Start by assessing your current state:

- Which of these 12 challenges resonate most with your situation?

- What’s the potential impact of solving your biggest inventory problems?

- What resources do you have available to implement solutions?

Remember, you don’t have to solve everything at once. Focus on the challenges with the highest impact on your business, implement solutions systematically, and build momentum through early wins.

Ready to transform your inventory management? The tools and strategies outlined in this guide provide a roadmap for overcoming common inventory management problems and building a more efficient, profitable operation.

Consider exploring Omneelab’s AI-powered inventory management solutions that can help automate many of these processes, provide real-time insights, and scale with your business growth. The investment in proper inventory management solutions typically pays for itself through improved efficiency, reduced costs, and better customer service.

Your inventory challenges are solvable – it’s time to take action and build the inventory management system your business deserves.

Frequently Asked Questions

The most common inventory management challenges include inaccurate demand forecasting, poor inventory visibility, stockouts and overstock situations, manual processes leading to errors, inadequate technology infrastructure, and lack of real-time data. These challenges often interconnect, where poor forecasting leads to stock issues, which then require manual interventions that create more errors.

Modern inventory management software addresses many core challenges through automation, real-time tracking, and data analytics. Barcode inventory tracking and RFID inventory solutions eliminate manual counting errors, while cloud-based inventory systems provide real-time visibility across multiple locations. Automated inventory control systems can trigger reorders, manage safety stock levels, and provide predictive analytics for better decision-making.

Small business inventory issues typically focus on limited resources, basic technology, and simpler processes that don’t scale well. Enterprise inventory solutions deal with complexity across multiple locations, channels, and product lines. However, both face similar core challenges like demand forecasting, stock optimization, and cost control – just at different scales and complexity levels.

Seasonal inventory planning requires predicting demand spikes months in advance, while promotional activities can create sudden demand surges. These variations challenge traditional forecasting methods and require flexible supplier relationships, strategic safety stock positioning, and careful coordination between marketing and operations teams. Retail inventory management problems often stem from poor seasonal and promotional planning.

Beyond obvious costs like stockouts and excess inventory, poor inventory management creates hidden expenses through increased labor costs from manual processes, higher inventory carrying costs from inefficient stock levels, customer dissatisfaction from service issues, and opportunity costs from tied-up capital. Inventory shrinkage control problems can also lead to significant losses through damage, obsolescence, and theft. Studies show that comprehensive inventory cost reduction strategies can improve profitability by 2-5% annually.

Kapil Pathak is a Senior Digital Marketing Executive with over four years of experience specializing in the logistics and supply chain industry. His expertise spans digital strategy, search engine optimization (SEO), search engine marketing (SEM), and multi-channel campaign management. He has a proven track record of developing initiatives that increase brand visibility, generate qualified leads, and drive growth for D2C & B2B technology companies.