The Indian fashion industry is experiencing unprecedented growth, with the market expected to reach $350 billion by 2030. However, managing seasonal inventory remains one of the biggest challenges for fashion brands across the country. From the scorching summer collections to festive wear during Diwali, fashion inventory management requires a delicate balance between meeting customer demand and avoiding costly dead stock.

If you’re a fashion brand owner struggling with seasonal transitions, overstocked warehouses, or missed sales opportunities, you’re not alone. The complexity of managing multiple sizes, colors, and styles across different seasons can overwhelm even experienced retailers. This is where a robust WMS for fashion brands becomes your secret weapon.

In this comprehensive guide, we’ll explore how seasonal inventory management can transform your fashion business operations, reduce costs, and maximize profitability during India’s diverse seasonal cycles.

Understanding Fashion Inventory Challenges in India

The Unique Indian Fashion Landscape

India’s fashion market presents unique challenges that international brands often underestimate. The country experiences distinct seasonal patterns influenced by monsoons, festivals, and regional preferences. Fashion brand WMS India solutions must account for these local nuances to be effective.

According to industry reports, Indian fashion retailers lose approximately 15-20% of their annual revenue due to poor inventory management, with seasonal misalignment being the primary culprit. This staggering figure highlights the critical importance of implementing sophisticated inventory management strategies.

Fast fashion inventory challenges in India include:

- Regional climate variations: What sells in Mumbai might not work in Delhi

- Festival-driven demand spikes: Diwali, Eid, and regional festivals create massive inventory fluctuations

- Price-sensitive consumers: Indian customers expect value, making markdown strategies crucial

- Size and fit preferences: Local body types require different size matrices

Common Inventory Pain Points

Most Fashion Brand WMS in India struggle with similar issues. Understanding these common inventory management challenges is the first step toward implementing effective solutions. Apparel inventory management challenges typically include:

- Inaccurate demand forecasting leading to stockouts or overstock

- Poor visibility across multiple sales channels

- Inefficient warehouse space utilization

- Complex size-color-style combinations creating tracking nightmares

- Seasonal transitions leaving brands with unsold inventory

What is Fashion Brand WMS?

Defining WMS for Fashion Retailers

A fashion retail inventory software is more than just a tracking system. It’s a comprehensive solution designed specifically for the unique needs of apparel businesses. Unlike generic inventory systems, apparel inventory management systems handle the complexity of fashion retail operations.

For fashion brands seeking a comprehensive solution, Omni-WMS offers specialized features designed to handle the unique complexities of fashion inventory management, including style-color-size tracking, seasonal planning, and multi-channel integration capabilities.

For fashion brand WMS selling on multiple platforms, understanding WMS integration types and benefits becomes crucial for seamless operations across channels.

Key features of fashion-focused WMS include:

- Style-color-size inventory tracking capabilities

- Advanced allocation and replenishment algorithms

- Integration with fashion-specific sales channels

- Seasonal planning and forecasting tools

- Markdown and promotion management

Why Generic WMS Falls Short

Traditional warehouse management systems weren’t built for fashion’s complexity. Clothing inventory management strategies require specialized functionality that generic systems simply can’t provide. Fashion brands need systems that understand the relationship between styles, colors, and sizes – not just SKU numbers.

Core Components of Seasonal Inventory Management

Understanding Seasonal Cycles

Seasonal inventory planning in fashion goes beyond just summer and winter collections. Indian fashion brands must navigate:

- Pre-season planning: Building inventory 3-6 months ahead

- In-season management: Real-time adjustments based on sales performance

- End-of-season clearance: Efficient markdown strategies to clear old stock

- Transition periods: Managing inventory between seasons

Research indicates that fashion brands with proper seasonal planning achieve 25-30% higher profit margins compared to those without structured seasonal strategies. This significant difference underscores the importance of implementing systematic seasonal inventory management approaches.

The Fashion Calendar Approach

Successful seasonal buying calendar fashion strategies involve detailed planning throughout the year. This includes:

Spring/Summer Planning (January-March):

- Light fabrics and bright colors

- Festival wear for Holi and regional celebrations

- Wedding season inventory

Monsoon Preparation (April-June):

- Waterproof and quick-dry materials

- Comfortable indoor wear

- Reduced outdoor event clothing

Festive Season (July-October):

- Traditional wear for Diwali and Durga Puja

- Premium fabrics and embellished pieces

- Gift-worthy packaging and presentation

Winter Collections (November-December):

- Warm clothing for northern regions

- Party wear for New Year celebrations

- Layering pieces for varying temperatures

Implementing WMS for Fashion Brands in India

Choosing the Right System

Fashion WMS implementation requires careful consideration of your specific needs. The best clothing retail inventory system for your brand depends on several factors. For comprehensive guidance, explore our detailed article on choosing the right warehouse management solution.

Business Size Considerations:

- Small brands (under ₹10 crores): Cloud-based solutions with basic forecasting

- Medium brands (₹10-100 crores): Integrated systems with advanced analytics

- Large brands (₹100+ crores): Enterprise solutions with AI-powered forecasting

Feature Priorities:

- Multi-channel integration capabilities

- Real-time inventory visibility

- Advanced reporting and analytics

- Scalability for future growth

Platform-Specific Integration Considerations

Fashion brands often sell across multiple e-commerce platforms. Consider these platform-specific WMS integrations:

- WMS for Myntra sellers – Essential for fashion brands targeting India’s largest fashion marketplace

- WMS for Shopify – Perfect for D2C fashion brands

- WMS for Nykaa integration – Crucial for beauty and fashion brands

- WMS for Ajio integration – Important for fashion brands on Reliance’s platform

Implementation Best Practices

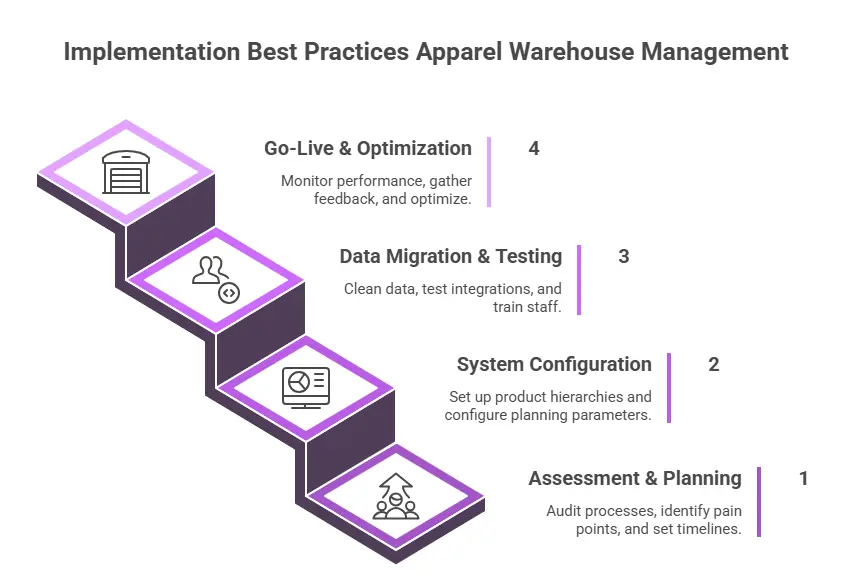

Successful apparel warehouse management India implementations follow proven methodologies:

Phase 1: Assessment and Planning

- Audit current inventory processes

- Identify pain points and requirements

- Set realistic timelines and budgets

Phase 2: System Configuration

- Set up product hierarchies (brand > category > style > color > size)

- Configure seasonal planning parameters

- Establish reorder points and safety stock levels

Phase 3: Data Migration and Testing

- Clean and migrate historical data

- Test all integrations thoroughly

- Train staff on new processes

Phase 4: Go-Live and Optimization

- Monitor system performance closely

- Gather user feedback and make adjustments

- Continuously optimize based on results

Advanced Seasonal Forecasting Techniques

Demand Forecasting for Fashion

Seasonal demand forecasting fashion requires sophisticated approaches that consider multiple variables. Traditional forecasting methods often fail in fashion because they don’t account for trend volatility and style lifecycle patterns.

Industry data shows that fashion brands wms using AI-powered forecasting tools reduce inventory holding costs by 20-35% while simultaneously improving stock availability by 15-25%. These improvements directly translate to better customer satisfaction and increased profitability.

Understanding demand-driven replenishment strategies can significantly improve your forecasting accuracy and inventory optimization.

Key Forecasting Factors:

- Historical sales data by season

- Weather patterns and climate predictions

- Fashion trend analysis and social media sentiment

- Economic indicators and consumer spending patterns

- Competitor analysis and market positioning

Leveraging Technology for Better Predictions

Modern fashion inventory forecasting tools use artificial intelligence and machine learning to improve accuracy. These systems analyze:

- Pattern Recognition: Identifying seasonal trends from historical data

- External Data Integration: Weather forecasts, social media trends, economic indicators

- Real-time Adjustments: Updating forecasts based on current sales performance

- Collaborative Planning: Incorporating buyer and merchandiser insights

Building Seasonal Models

Effective apparel demand planning requires building separate models for different product categories:

Basic Items (jeans, t-shirts, undergarments):

- Steady demand with minimal seasonal variation

- Focus on size and color distribution

- Longer lead times acceptable

Fashion Items (trendy tops, seasonal dresses):

- High seasonal variation

- Shorter lifecycle requiring quick response

- Higher risk but better margins

Seasonal Specialties (winter wear, festive clothing):

- Extreme seasonal concentration

- Requires precise timing and quantities

- High clearance risk if overstocked

Optimizing Inventory Across Seasons

Strategic Stock Planning

Fashion stock optimization involves balancing multiple competing priorities. You want enough inventory to capture sales opportunities while minimizing carrying costs and markdown risks.

Learn more about strategies to improve inventory turnover to maximize your seasonal inventory efficiency.

Inventory Segmentation Strategies:

A-Items (Top 20% of styles):

- Higher safety stock levels

- More frequent replenishment

- Priority allocation to best-performing stores

B-Items (Middle 60% of styles):

- Moderate safety stock

- Standard replenishment cycles

- Balanced allocation across channels

C-Items (Bottom 20% of styles):

- Minimal safety stock

- Longer replenishment cycles

- Limited distribution to test markets

Managing Size and Color Matrices

Apparel size matrix management is crucial for fashion success. Indian consumers have diverse size requirements, and getting the mix wrong can be costly.

Size Planning Best Practices:

- Analyze historical size curves by region

- Adjust for local preferences and demographics

- Consider seasonal variations (winter sizes often run larger)

- Plan for size substitution patterns

Color Strategy Considerations:

- Regional color preferences vary significantly

- Seasonal color trends change rapidly

- Consider cultural and religious factors

- Plan for color substitution possibilities

Warehouse Space Optimization

Fashion inventory optimization extends beyond just quantities to physical space management. Fashion items have unique storage requirements that impact warehouse efficiency.

For detailed insights on managing warehouse capacity, read our guide on warehouse overflow challenges and solutions.

Space Planning Strategies:

- Seasonal Zones: Dedicate areas for current season merchandise

- Hanging vs. Folded: Optimize based on garment type and value

- Pick Path Efficiency: Place fast-moving items in easily accessible locations

- Expansion Planning: Account for seasonal volume fluctuations

Technology Integration and Automation

Multi-Channel Inventory Synchronization

Modern fashion brands sell across multiple channels – online marketplaces, own websites, physical stores, and wholesale partners. Fashion inventory visibility across all channels is essential for success.

Studies reveal that fashion retailers with integrated multi-channel inventory systems experience 40% fewer stockouts and 30% reduction in excess inventory compared to those managing channels separately. This integration becomes even more critical during seasonal transitions when inventory allocation decisions can make or break profitability.

Understanding inventory visibility in 2025 trends can help you stay ahead of the competition.

Integration Requirements:

- Real-time inventory updates across all channels

- Centralized order management

- Automated allocation rules

- Channel-specific pricing and promotion management

Automation Opportunities

Fashion supply chain management India benefits significantly from automation. Key areas for automation include:

Replenishment Automation:

- Automatic reorder point calculations

- Seasonal adjustment factors

- Supplier lead time optimization

- Exception-based management

Learn about types of inventory replenishment to choose the best approach for your fashion brand.

Allocation Automation:

- Store-specific size curves

- Performance-based allocation

- New store ramp-up profiles

- Seasonal transition planning

Advanced Tracking Technologies

Modern fashion brands are adopting advanced tracking technologies:

- Barcode technology for inventory management – Essential for accurate tracking

- QR codes for inventory and warehouse management – Improving efficiency and accuracy

- RFID for inventory management – Advanced tracking with pros and cons to consider

Last-Mile Delivery Optimization for Fashion Brands

Integrating Delivery Management with Inventory

Fashion brands must coordinate inventory management with efficient last-mile delivery to ensure customer satisfaction during seasonal peaks. The integration between warehouse operations and delivery logistics becomes crucial during high-demand periods like festival seasons.

For fashion brands looking to optimize their delivery operations, Last Mile SaaS provides AI-powered route optimization and real-time tracking capabilities that seamlessly integrate with your inventory management system, ensuring efficient order fulfillment from warehouse to customer doorstep.

Key Integration Benefits:

- Real-time inventory allocation based on delivery capacity

- Optimized picking sequences for faster order processing

- Coordinated seasonal delivery planning

- Enhanced customer communication during peak seasons

Performance Measurement and KPIs

Essential Fashion Inventory Metrics

Fashion brand inventory KPIs differ from general retail metrics. Fashion-specific measurements include:

Inventory Turnover Metrics:

- Overall inventory turnover (target: 4-6x annually)

- Seasonal turnover rates

- Category-specific turnover

- Style lifecycle performance

Sell-Through Rates:

- Weekly sell-through by style

- Seasonal sell-through targets

- Channel-specific performance

- Size and color sell-through analysis

Markdown and Margin Metrics:

- Markdown percentage by season

- Gross margin protection

- Full-price sell-through rates

- Clearance efficiency metrics

Seasonal Performance Analysis

Fashion inventory aging analysis helps identify problems before they become costly. Regular analysis should include:

Age Segmentation:

- 0-30 days: Fresh inventory

- 31-60 days: Monitor closely

- 61-90 days: Markdown consideration

- 90+ days: Aggressive clearance needed

Seasonal Transition Metrics:

- Carryover inventory levels

- Transition timing efficiency

- New season ramp-up speed

- Customer satisfaction during transitions

For comprehensive inventory tracking, consider implementing mastering inventory audits practices to ensure accuracy throughout seasonal transitions.

Managing Seasonal Transitions

End-of-Season Strategies

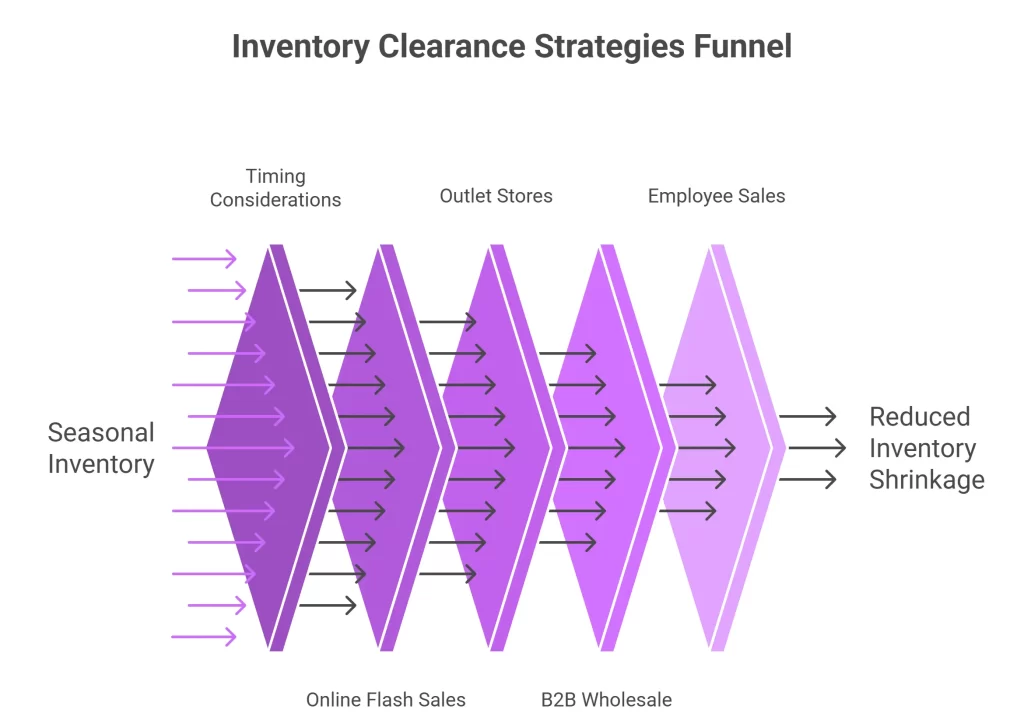

Fashion markdown strategies are crucial for maintaining healthy inventory levels. Effective clearance strategies include:

Timing Considerations:

- Start markdowns before season ends

- Gradual price reductions vs. deep immediate cuts

- Channel-specific markdown timing

- Inventory velocity monitoring

Clearance Channel Strategy:

- Online flash sales for broad reach

- Outlet stores for physical clearance

- B2B wholesale for bulk movement

- Employee sales for final clearance

Understanding inventory shrinkage and prevention methods is crucial during clearance periods to minimize losses.

Preparing for New Seasons

Seasonal fashion buying requires careful coordination between clearance and new arrivals. Best practices include:

Inventory Clean-Up:

- Complete previous season clearance

- Warehouse space preparation

- Staff training on new collections

- System updates for new styles

New Season Launch:

- Coordinated marketing campaigns

- Staff product knowledge training

- Inventory allocation optimization

- Performance monitoring setup

Challenges and Solutions

Common Implementation Hurdles

WMS implementation guide for Indian fashion brands must address typical challenges:

Data Quality Issues:

- Inconsistent product information

- Missing historical data

- Multiple data sources

- Manual data entry errors

Change Management Resistance:

- Staff reluctance to adopt new systems

- Lack of proper training

- Insufficient management support

- Unrealistic timeline expectations

Overcoming Regional Challenges

Fashion inventory management during festival seasons India presents unique challenges:

Festival Season Preparation:

- Demand spikes can be 3-5x normal levels

- Regional preferences vary significantly

- Supply chain constraints during festivals

- Cash flow management during high inventory periods

Regional Customization:

- Size preferences vary by region

- Color and style preferences differ

- Climate considerations affect timing

- Local competition impacts strategy

Future Trends and Innovations

Emerging Technologies

The future of fashion trend forecasting includes exciting technological developments:

Artificial Intelligence Applications:

- Predictive analytics for trend identification

- Automated buying recommendations

- Dynamic pricing optimization

- Customer behavior prediction

IoT and Smart Warehousing:

- RFID tracking for real-time visibility

- Smart sensors for environmental monitoring

- Automated sorting and picking systems

- Predictive maintenance for equipment

Explore the future of warehouse management trends 2025 to stay ahead of industry developments.

Sustainability Considerations

Modern fashion brand supply chain optimization must consider environmental impact:

Sustainable Practices:

- Reduced overproduction through better forecasting

- Circular fashion initiatives

- Sustainable packaging solutions

- Carbon footprint reduction strategies

Conclusion

Mastering seasonal inventory management is essential for fashion brand success in India’s dynamic market. The right apparel inventory management system can transform your operations, reduce costs, and improve customer satisfaction.

Key takeaways for implementing effective fashion inventory management include:

- Invest in fashion-specific WMS technology

- Develop sophisticated forecasting capabilities

- Optimize inventory across all seasons and channels

- Measure performance with fashion-relevant KPIs

- Plan for seasonal transitions well in advance

The fashion industry’s complexity requires specialized solutions. Generic inventory systems simply can’t handle the nuances of style-color-size combinations, seasonal variations, and trend-driven demand patterns that define fashion retail.

For a comprehensive understanding of inventory management fundamentals, explore our comprehensive guide to inventory management systems.

Ready to revolutionize your fashion inventory management? Explore advanced WMS solutions designed specifically for Indian fashion brands. Contact our experts today to discover how the right technology can transform your seasonal inventory challenges into competitive advantages.

Frequently Asked Questions

Fashion brands manage seasonal inventory through strategic planning, advanced forecasting, and specialized WMS systems. Key strategies include developing seasonal buying calendars, implementing style-color-size tracking, using AI-powered demand forecasting, and establishing efficient markdown processes. Successful brands also maintain separate inventory models for basic items, fashion items, and seasonal specialties.

The best WMS for Indian fashion retailers depends on business size and requirements. Small brands benefit from cloud-based solutions with basic forecasting, while larger brands need enterprise systems with AI-powered analytics. Key features to look for include multi-channel integration, real-time inventory visibility, seasonal planning tools, and support for complex size-color-style matrices.

Fashion brands can reduce dead stock by implementing accurate demand forecasting, optimizing size and color matrices, establishing proper markdown strategies, and using real-time sales data for quick adjustments. Target inventory turnover rates of 4-6x annually, monitor sell-through rates weekly, and start markdowns before seasons end to maintain healthy inventory levels.

Major challenges include regional climate variations, festival-driven demand spikes, complex size-color-style combinations, price-sensitive consumers, and managing inventory across multiple sales channels. Indian fashion brands must also navigate seasonal transitions, cultural preferences, and supply chain constraints during peak seasons like Diwali and wedding seasons.

Fashion brands should start seasonal planning 3-6 months in advance, develop festival-specific inventory strategies, and implement gradual clearance processes for old stock. Key steps include analyzing historical festival sales data, adjusting inventory levels for 3-5x demand spikes, coordinating marketing campaigns with inventory availability, and preparing warehouse space for seasonal merchandise transitions.

People also read:

- WMS for Tata CLiQ

- WMS for Snapdeal

- WMS for Myntra Sellers in India

- WMS for Nykaa Integration Guide

- Amazon FBA vs WMS Integration

Kapil Pathak is a Senior Digital Marketing Executive with over four years of experience specializing in the logistics and supply chain industry. His expertise spans digital strategy, search engine optimization (SEO), search engine marketing (SEM), and multi-channel campaign management. He has a proven track record of developing initiatives that increase brand visibility, generate qualified leads, and drive growth for D2C & B2B technology companies.