Choosing the right warehouse tracking technology can make or break your inventory management efficiency. If you’re running a warehouse in India and wondering whether to stick with traditional barcode systems or upgrade to RFID technology, you’re not alone. This decision impacts everything from your operational costs to order fulfillment accuracy.

Let’s break down the barcode vs RFID debate with real numbers, practical insights, and honest comparisons that’ll help you make an informed decision for your warehouse operations.

Understanding Barcode and RFID Technologies

Before diving into comparisons, let’s understand what we’re dealing with.

Barcode systems use optical scanning to read printed labels. You’ve seen them everywhere from retail products to warehouse pallets. A barcode scanner warehouse setup requires line of sight scanning, meaning your staff needs to point the scanner directly at each barcode to capture data. For comprehensive understanding of how barcode technology works in inventory management, modern systems have evolved significantly beyond basic scanning.

RFID (Radio Frequency Identification) takes a different approach. Instead of optical scanning, it uses radio waves to communicate with tags attached to items. The beauty of this non-line-of-sight technology is that you don’t need to see the tag to read it. Walk past a pallet with hundreds of items? Your RFID reader can capture all those tags simultaneously. Learn more about RFID technology and its industry applications to understand its full potential.

Think of it this way: barcodes are like reading a book—you need to look at each page individually. RFID is like having a conversation in a room—you can hear multiple voices at once without looking directly at each person.

The Technology Showdown: How They Actually Work

Barcode Technology in Action

Barcode scanning accuracy warehouse operations depend on a sequential scanning process. Your warehouse staff uses handheld scanners or fixed scanners to read one-dimensional or two-dimensional codes. Each scan captures data instantly, but here’s the catch—you can only scan one item at a time.

The read range distance for barcodes is typically 6-12 inches. Your scanner needs to be close, the barcode needs to be clean, and the alignment must be right. Damaged or dirty labels? That’s a manual entry waiting to happen, which increases human error potential. For detailed insights on warehouse barcode scanning for 3PL operations, implementation strategies vary by operation size.

RFID Technology Explained

RFID barcode inventory tracking systems operate differently. You’ve got two main types: passive RFID tags and active RFID tags. Passive tags don’t have their own power source—they’re energized by the reader. Active tags have batteries and can transmit signals over longer distances.

The bulk scanning capability is where RFID shines. Fixed RFID readers installed at dock doors can read hundreds of tags per second as items move through. Handheld RFID scanners let workers capture entire pallet inventories in seconds without unpacking anything. Explore the pros and cons of RFID for inventory management to understand implementation considerations.

Read range? Passive tags work from 1-10 meters, while active tags can reach up to 100 meters. That’s the difference between standing next to your inventory and reading it from across the warehouse floor.

Cost Comparison: The Real Investment Breakdown

Let’s talk money—because that’s what keeps warehouse managers up at night.

Barcode System Costs

Starting with barcode scanner warehouse systems is relatively affordable:

- Handheld barcode scanners: ₹8,000 – ₹40,000 per unit

- Barcode labels: ₹0.10 – ₹2 per label

- Barcode printers: ₹15,000 – ₹1,50,000

- WMS integration: ₹50,000 – ₹5,00,000 (depending on complexity)

- Installation setup costs: Minimal, mostly plug-and-play

For a mid-sized warehouse in India, you’re looking at an initial investment of ₹2-5 lakhs for a complete barcode system. The deployment complexity is low, and most operations can be up and running within days. Check out small business barcoding solutions for budget-friendly implementation strategies.

RFID Implementation Cost Breakdown

RFID implementation cost warehouse setups require a bigger upfront commitment:

- Passive RFID tags: ₹5 – ₹50 per tag (volume dependent)

- Active RFID tags: ₹200 – ₹2,000 per tag

- On-metal tags: ₹30 – ₹100 per tag (for metal surfaces)

- Fixed RFID readers: ₹1,50,000 – ₹8,00,000 per unit

- Handheld RFID scanners: ₹80,000 – ₹3,00,000 per device

- RFID warehouse management system software: ₹5,00,000 – ₹25,00,000

- Infrastructure and installation: ₹3,00,000 – ₹15,00,000

- Cloud deployment or perpetual license options available

Total initial investment for RFID? Expect ₹15-50 lakhs for a medium-sized warehouse. Yes, that’s 5-10 times more than barcodes. But hold on we’ll get to ROI shortly.

Hidden Costs to Consider

Barcode systems:

- Label replacement (damaged, faded, torn labels)

- Labor costs for sequential scanning

- Downtime from scan failures

- Data entry errors requiring corrections

RFID systems:

- Tag costs (though decreasing annually)

- Reader maintenance and calibration

- Software updates and support

- Staff training on new technology

Accuracy Comparison: Precision That Matters

Accuracy isn’t just a nice-to-have; it’s the foundation of efficient warehouse operations. Understanding common inventory management challenges helps contextualize why accuracy matters so much.

Barcode Scanning Accuracy

Barcode scanning accuracy warehouse metrics typically show:

- Scan accuracy: 85-95% (when labels are clean and properly aligned)

- Human error rate: 1-2% during manual scanning

- Inventory accuracy rate: 75-85% without automation support

- Data capture speed: 1-2 seconds per item

The challenges? Dirty labels, poor lighting, damaged barcodes, and scanning fatigue all reduce accuracy. Your warehouse staff might scan hundreds or thousands of items daily; maintaining focus and precision becomes difficult.

RFID Accuracy Performance

RFID systems deliver impressive numbers:

- Read accuracy: 99.9% or higher

- Inventory accuracy rate: 95-99% with proper implementation

- Simultaneous tag reading: 200-1,000 tags per second

- Data capture speed: Near-instantaneous for bulk items

- Human error reduction: 90% decrease compared to manual methods

The real-time visibility provided by RFID means your inventory reconciliation happens continuously, not just during scheduled cycle counting sessions. Stock level tracking becomes automatic rather than periodic. Learn about inventory visibility in 2025 and how technology enables real-time tracking.

Speed and Efficiency: Time Is Money

Let’s compare actual warehouse scenarios:

Receiving 500 cartons:

- Barcode: 2-3 hours with two workers (sequential scanning process)

- RFID: 15-30 minutes with one worker (bulk scanning capability)

Inventory cycle counting (1,000 SKUs):

- Barcode: 6-8 hours

- RFID: 1-2 hours

Order picking accuracy:

- Barcode: 95-97% (with careful scanning)

- RFID: 99%+ (automatic verification)

The processing time reduction with RFID isn’t marginal; it’s transformational. Your warehouse can handle 3-4 times more throughput with the same number of staff members. Discover warehouse order picking process methods to optimize your fulfillment operations.

ROI Calculation: When Does RFID Pay Off?

Here’s where theory meets reality. RFID ROI warehouse calculations depend on several factors.

Calculating Your Return on Investment

Let’s work through a real example for an Indian e-commerce warehouse:

Scenario: 10,000 SKUs, 2,000 daily transactions, 20 warehouse staff

Barcode annual costs:

- Labor (scanning/verification): ₹60,00,000

- Error corrections: ₹8,00,000

- Label replacement: ₹1,00,000

- Total: ₹69,00,000

RFID annual costs after implementation:

- Reduced labor: ₹35,00,000

- Tag replacement: ₹4,00,000

- System maintenance: ₹3,00,000

- Total: ₹42,00,000

Annual savings: ₹27,00,000

Initial RFID investment: ₹35,00,000

ROI timeframe: 15-18 months

Add to this the operational savings from:

- Shrinkage reduction: 2-3% of inventory value recovered (learn about inventory shrinkage prevention)

- Labor cost reduction: 30-40% in picking and receiving

- Order fulfillment accuracy improvement: 3-5% increase in customer satisfaction

- Asset utilization improvement: 15-20% better space utilization

When RFID Makes Sense

RFID typically delivers better ROI when you have:

- High-value inventory (where shrinkage costs are significant)

- Large volume operations (1,000+ daily transactions)

- Complex supply chains requiring real-time visibility (explore visibility in supply chain digitization)

- Quick commerce warehouse management needs (10-15 minute delivery windows)

- E-commerce inventory tracking with multiple channels

- Industries like fashion retail, pharmaceuticals, or electronics

When Barcodes Are Still Better

Stick with barcodes if:

- You’re running a small warehouse (under 5,000 SKUs)

- Budget constraints are tight (under ₹10 lakhs available)

- Your inventory turnover is slow

- Items are easily accessible and well-organized

- You don’t need real-time tracking

Integration with Warehouse Management Systems

Both technologies need proper WMS integration to deliver value. Understanding comprehensive inventory management systems is crucial for successful implementation.

Modern warehouse management system integration supports:

- Real-time inventory updates

- Automated reorder triggers

- Data entry automation

- Multi-location tracking

- Stock-taking automation

- Inventory optimization algorithms

The difference? RFID provides continuous data flow, while barcodes provide point-in-time snapshots. For quick commerce and fast-moving e-commerce inventory tracking, that real-time difference matters enormously.

Many Indian warehouses are adopting hybrid solutions—using barcodes for slow-moving items and RFID for high-velocity products. This RFID barcode hybrid system balances cost with performance. Learn about technologies in warehousing logistics in India for emerging trends.

Practical Implementation Considerations

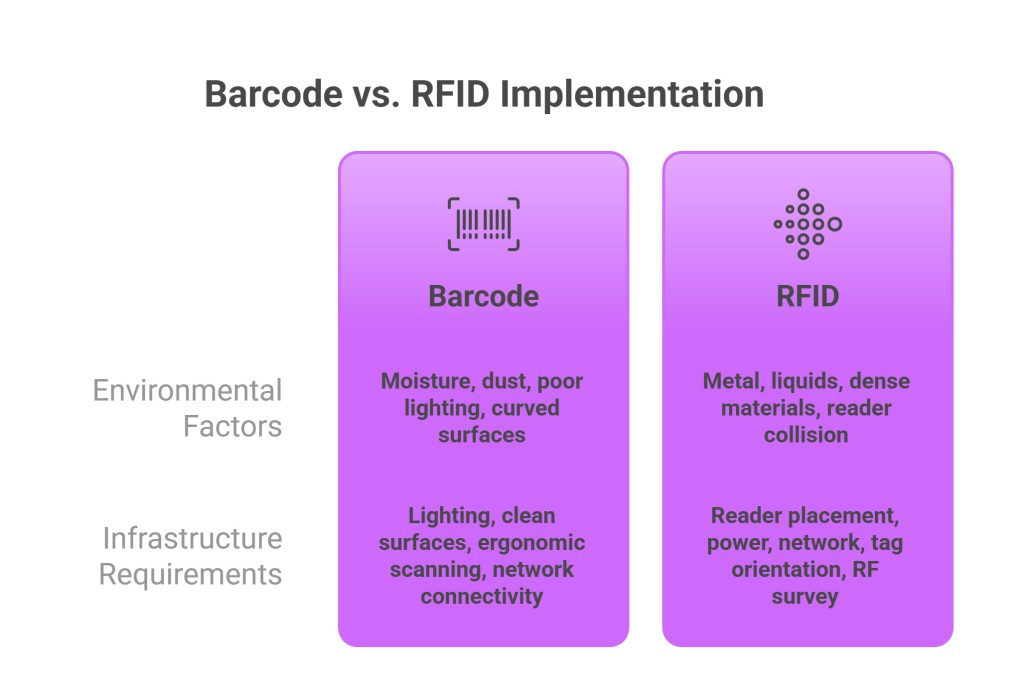

Environmental Factors

Barcodes struggle with:

- Moisture and humidity (label degradation)

- Dust and dirt (scanning failures)

- Poor lighting conditions

- Label placement on curved surfaces

RFID faces challenges with:

- Metal surfaces (requiring special on-metal tags)

- Liquid-filled products (signal interference)

- Dense materials (reduced read range)

- Reader collision in tight spaces

Infrastructure Requirements

Your warehouse needs assessment should include:

For barcodes:

- Adequate lighting throughout facility

- Clean, flat surfaces for label placement

- Ergonomic scanning positions

- Network connectivity for real-time updates

For RFID:

- Reader placement at strategic chokepoints

- Power infrastructure for fixed readers

- Network infrastructure for data transmission

- Tag orientation guidelines for optimal reads

- RF environment survey before installation

The Future of Warehouse Tracking Technology

The warehouse tracking technology landscape is evolving rapidly. We’re seeing:

- IoT sensors warehouse management combining RFID with temperature, humidity, and location sensors for comprehensive monitoring.

- AI-powered warehouse tracking using computer vision alongside RFID to verify product conditions and placement accuracy.

- Cloud-based inventory management platforms offering software-as-a-service models that reduce upfront costs and improve scalability. Explore the role of cloud retail WMS in supply chain for modern deployment options.

- Multi-technology warehouse tracking solutions that intelligently switch between barcode, RFID, and computer vision based on the task at hand.

For Indian warehouses serving the booming quick commerce sector, the trend is clear—automation is no longer optional. Customer expectations for 10-15 minute deliveries demand the speed and accuracy that only automated systems can provide. Check out future warehouse management trends for 2025 to stay ahead.

Making Your Decision

So, which technology wins the RFID vs barcode warehouse management debate?

The honest answer: it depends on your specific situation.

Choose RFID if:

- You handle more than ₹10 crore inventory annually

- Speed and accuracy directly impact customer satisfaction

- You’re losing 2-3%+ to inventory shrinkage

- Labor costs represent 40%+ of your operational expenses

- You need real-time visibility across multiple locations

- You’re scaling rapidly and need automation

Choose barcodes if:

- You’re operating on a tight budget

- Your current system works adequately

- You have fewer than 500 daily transactions

- Your inventory is easily accessible and organized

- You can afford 24-48 hour inventory visibility lag

Consider hybrid if:

- You want to test RFID on high-value items first

- Different product categories have different tracking needs

- You’re planning gradual automation over 2-3 years

Conclusion

The barcode vs RFID comparison isn’t about declaring a universal winner, it’s about finding the right asset tracking technology for your specific warehouse operations.

Barcodes offer simplicity, affordability, and reliability for straightforward operations. RFID delivers speed, accuracy, and productivity improvement for complex, high-volume environments.

For Indian warehouses, especially those serving e-commerce and quick commerce channels, the question isn’t whether to automate, but when and how. Start by calculating your potential ROI, assessing your operational pain points, and determining your growth trajectory. If you’re just getting started, explore introduction to warehouse management fundamentals.

Ready to upgrade your warehouse management system? Begin with a pilot program on your fastest-moving product lines. Test both technologies in your actual environment. Measure the results against your KPIs. Then make an informed decision based on data, not just technology hype. For guidance on choosing the right warehouse management solution, consider your specific business requirements.

The future of warehouse management in India is automated, accurate, and efficient. Whether you get there with barcodes, RFID, or a hybrid approach depends on your unique business needs. The important thing is to start moving forward today.

Frequently Asked Questions

Barcodes require line of sight scanning—you must point a scanner directly at each label to read one item at a time. RFID uses radio waves and doesn’t need line of sight, allowing you to scan multiple items simultaneously, reading hundreds of tags per second as items pass by readers.

Barcode systems cost ₹2-5 lakhs for initial setup in a mid-sized warehouse, while RFID implementation ranges from ₹15-50 lakhs. However, RFID systems often achieve ROI within 15-24 months through labor cost reduction, improved accuracy, and shrinkage prevention.

Yes! Many warehouses use hybrid systems—barcodes for slow-moving, low-value items and RFID for high-velocity, high-value inventory. Modern WMS integration supports both technologies simultaneously, allowing gradual transition based on your operational needs.

Barcode systems achieve 85-95% read accuracy with overall inventory accuracy of 75-85% due to human error. RFID delivers 99.9% read accuracy with 95-99% overall inventory accuracy, reducing human error by approximately 90%.

ROI typically occurs within 12-24 months for medium to large warehouses. Faster ROI comes from high inventory value, 1,000+ daily transactions, 30-40% labor cost reduction, and 2-3% shrinkage recovery, especially for quick commerce or e-commerce operations.

Kapil Pathak is a Senior Digital Marketing Executive with over four years of experience specializing in the logistics and supply chain industry. His expertise spans digital strategy, search engine optimization (SEO), search engine marketing (SEM), and multi-channel campaign management. He has a proven track record of developing initiatives that increase brand visibility, generate qualified leads, and drive growth for D2C & B2B technology companies.