Imagine this scenario: A customer in Mumbai reports a defective part in your product. Within minutes, you can identify exactly which batch it came from, which supplier in Gujarat provided the raw materials, and which production line in your Pune facility assembled it. That’s the power of traceability in manufacturing.

As India positions itself as a global manufacturing hub under the Make in India initiative, traceability has become more critical than ever. With a median age of just 28 years, India has a significant demographic advantage that ensures a steady flow of workers and keeps the domestic economy competitive. But to truly compete on the global stage, Indian manufacturers must adopt world-class quality and traceability standards.

In today’s complex manufacturing landscape, knowing where your products come from and where they go isn’t just nice to have. It’s essential for survival. From product recalls to regulatory audits, manufacturers face constant pressure to account for every component, every process, and every finished product.

But what exactly is manufacturing traceability? How does it work? And why should Indian businesses care?

In this comprehensive guide, we’ll break down everything you need to know about product traceability in the Indian context. You’ll learn about different types of traceability systems, the industries that require them, and practical steps to implement traceability in your own operations. Whether you’re running a small MSME in Coimbatore or managing a large-scale operation in the NCR region, this article will help you understand why traceability matters and how to get started. Let’s dive in.

What Is Traceability in Manufacturing?

At its core, traceability in manufacturing is the ability to track and trace products, components, and materials throughout the entire production process. Think of it as creating a detailed family tree for every item you produce.

Manufacturing traceability answers critical questions like:

- Where did this raw material come from?

- Which machines processed this component?

- Who worked on this product and when?

- Where did the finished product go after leaving the facility?

This information creates what experts call an audit trail. It’s a complete record of a product’s journey from raw materials to the customer’s hands. To achieve this level of visibility, companies need robust inventory management systems that capture and organize data at every step.

For Indian manufacturers looking to export globally or supply to multinational companies, this level of documentation is non-negotiable. International buyers expect complete transparency about product origins and manufacturing processes.

Forward vs. Backward Traceability

There are two main directions traceability can flow:

Forward traceability tracks products from their origin to their final destination. If you discover a problem with a batch of raw materials from a supplier in Ahmedabad, forward traceability helps you identify all the finished products that might be affected, whether they’ve been shipped to Delhi, Chennai, or exported overseas.

Backward traceability works in reverse. When a customer reports a defect, you can trace back through the production process to find the root cause. This is crucial for quality control manufacturing and continuous improvement.

The best manufacturing traceability solutions provide both directions. This creates what’s known as end-to-end traceability, giving you complete visibility across your entire operation.

Why Is Traceability Important in Manufacturing?

You might be wondering: “Is traceability really worth the investment for my Indian business?” The short answer is yes. Here’s why.

Quality Control and Defect Prevention

Quality issues happen. That’s a fact of manufacturing life. But how you respond makes all the difference.

With robust production traceability, you can quickly isolate problems before they spread. Instead of recalling an entire product line distributed across India’s vast geography, you can target only the affected batches. This saves money, protects your reputation, and keeps customers happy.

Track and trace systems also help you identify patterns. Maybe defects spike when a particular machine is used. Or perhaps issues correlate with specific suppliers. This data drives smarter decisions and prevents future problems.

Regulatory Compliance

Here’s a reality check: Many industries in India legally require traceability.

The FSSAI mandates traceability for food products. The CDSCO regulates pharmaceutical traceability. Automotive manufacturers supplying to OEMs must meet IATF 16949 standards. Export-oriented units face scrutiny from international regulatory bodies as well.

Failing to meet these standards can result in fines, licence cancellations, and legal consequences. Compliance management isn’t optional in these industries. It’s the cost of doing business.

Supply Chain Visibility

Traceability and supply chain visibility go hand in hand. When you can trace every component back to its source, you gain unprecedented insight into your entire supply network. This visibility helps you anticipate disruptions, manage supplier relationships, and make data-driven decisions.

Given India’s complex supply chains spanning multiple states with different tax regimes (even post-GST), this visibility becomes even more critical.

Supporting Make in India Goals

The government aims to make India a leading destination for foreign direct investment and a leader in design and innovation. For this vision to succeed, Indian manufacturers must demonstrate world-class quality systems. Traceability is a fundamental requirement for any company hoping to integrate into global supply chains.

Labour-intensive sectors such as toys, apparel, tourism, and logistics are being prioritised for growth. Companies in these sectors that implement strong traceability systems will have a competitive advantage when bidding for international contracts.

Recall Management

Product recalls are every manufacturer’s nightmare. They’re expensive, damaging to your brand, and stressful for everyone involved.

But effective recall management depends entirely on traceability. Without it, you’re forced to recall everything. You can’t identify which products are affected and which are safe.

Consider this: A targeted recall might cost a few lakh rupees. A blanket recall could cost crores. The math speaks for itself.

What Are the Different Types of Traceability?

Not all traceability systems work the same way. The right approach depends on your products, industry, and regulatory requirements. Understanding the difference between unit-level vs. batch-level traceability is essential for choosing the right approach for your operation.

Batch and Lot Traceability

Batch traceability (also called lot tracking in manufacturing) groups products made under similar conditions. All items in a batch share the same raw materials, production date, and processing parameters.

This approach works well for:

- Food and beverage production

- Chemical manufacturing

- Pharmaceutical products

- Bulk materials

- Textile manufacturing

When an issue arises, you can trace and potentially recall an entire batch rather than individual units. For industries dealing with perishable goods, implementing batch and expiry tracking is particularly critical for compliance and safety.

Serial Number Tracking

Serial number tracking assigns a unique identifier to every individual product. This provides the highest level of granularity.

Industries that rely on serialization include:

- Electronics manufacturing in hubs like Noida and Chennai

- Automotive components (especially safety-critical parts)

- Medical devices

- High-value consumer goods

While more resource-intensive than batch tracking, serial number tracking offers precise control over every unit produced. This is especially important for Indian e-commerce businesses dealing with returns and warranty claims.

Component and Part Traceability

Complex products often contain hundreds or thousands of parts. Component traceability tracks each piece that goes into the final assembly.

This is essential for genealogy tracking, where you need to know the complete history of every component. It’s particularly important in industries where a single faulty part can cause catastrophic failures.

Material Traceability

Material traceability focuses on raw materials and their properties. Where did the cotton come from? What certifications does the steel have? What were the test results?

This type of traceability ensures that only approved, certified materials enter your production process. It’s a cornerstone of chain of custody documentation. For Indian textile manufacturers looking to export to Europe or the US, material traceability is often mandatory to prove ethical sourcing.

Which Industries in India Require Manufacturing Traceability?

While traceability benefits virtually every manufacturer, some industries in India have mandatory requirements.

Automotive Manufacturing

India’s automotive industry, centred around hubs in Chennai, Pune, and Gurugram, follows IATF 16949 quality management standards. These require detailed traceability for safety-critical components like brakes, airbags, and steering systems.

Why traceability matters in the automotive industry goes beyond compliance. With lakhs of vehicles on Indian roads, even small defects can affect thousands of consumers. Precise traceability limits exposure and speeds up recalls.

Indian auto component manufacturers supplying to global OEMs must meet the same standards as their counterparts anywhere in the world.

Textile and Apparel

India’s textile industry is one of the largest employers in the country. With increasing focus on ethical sourcing and sustainability, international buyers now demand complete traceability from cotton field to finished garment.

Brands want to verify that materials are sourced responsibly, that factories meet labour standards, and that products don’t contain harmful chemicals. Natural, eco-friendly ingredients and transparent labelling can appeal significantly to conscious consumers.

For entrepreneurs looking to start manufacturing textiles, implementing traceability from day one will open doors to premium export markets.

Food and Beverage

Food manufacturing traceability has gained urgency following contamination incidents. The FSSAI requires detailed record-keeping throughout the supply chain.

From farm to plate, producers must document every step. This allows rapid response when contamination is detected. Companies in this sector benefit from specialized WMS solutions for food and beverage operations that handle the unique challenges of perishable inventory.

With India’s growing food processing industry and expanding cold chain infrastructure, traceability systems are becoming standard requirements. Proper handling of perishable inventory requires robust systems that can track shelf life and storage conditions.

Pharmaceutical and Healthcare

Pharmaceutical traceability regulations aim to prevent counterfeit drugs from entering the supply chain. India, being the pharmacy of the world, faces particular scrutiny in this area.

The CDSCO has been tightening regulations, and global importers demand complete track-and-trace capabilities. A dedicated pharmaceutical warehouse management system helps companies meet these stringent requirements while maintaining operational efficiency.

Patient safety depends on knowing exactly what’s in every tablet and where it came from.

E-commerce and D2C Brands

India’s booming e-commerce sector has created new traceability challenges. With products moving through multiple fulfilment centres and last-mile delivery partners, maintaining visibility is complex.

Direct-to-consumer brands especially need traceability to handle returns, warranty claims, and customer complaints efficiently. Whether you’re selling on Amazon, Flipkart, or your own Shopify store, traceability improves customer experience. Proper stock management for e-commerce depends heavily on accurate traceability data.

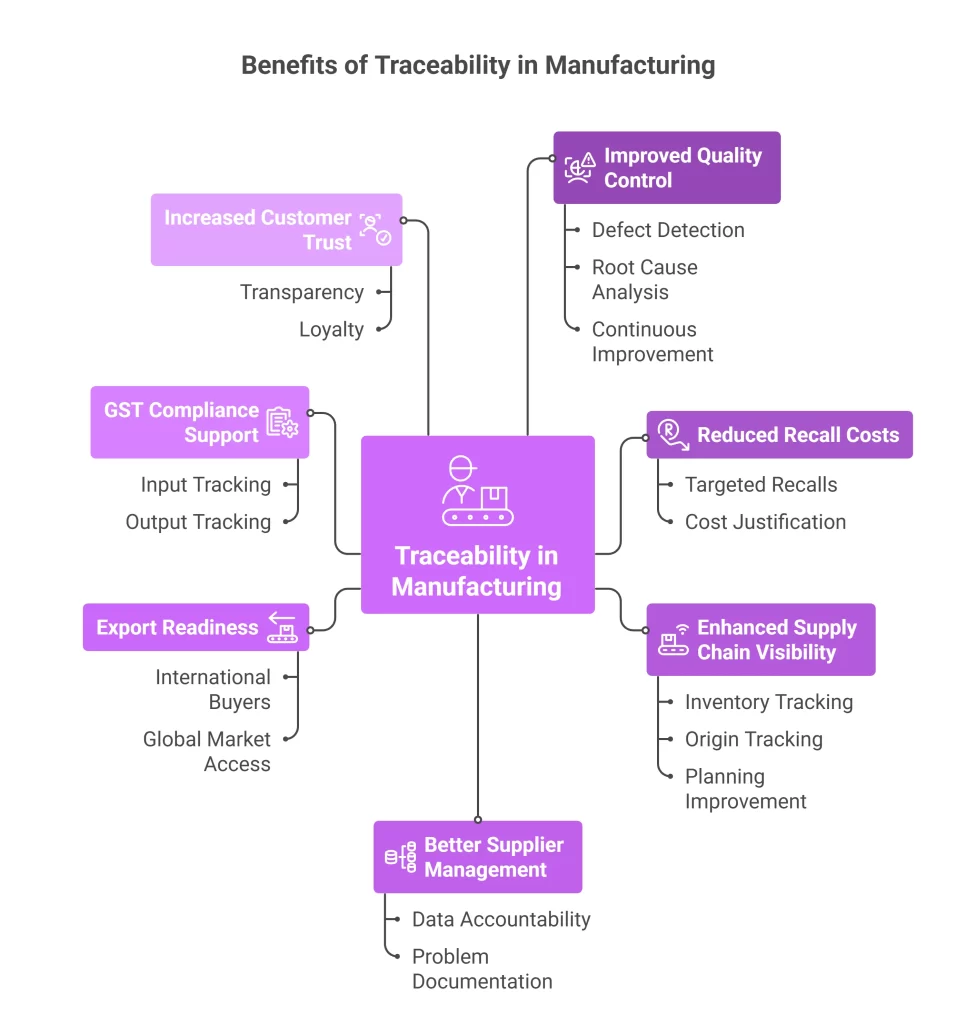

What Are the Benefits of Traceability in Manufacturing?

Beyond regulatory compliance, traceability delivers tangible business benefits for Indian manufacturers.

- Improved Quality Control Catch defects faster. Identify root causes. Prevent recurrence. Traceability data powers continuous improvement.

- Reduced Recall Costs Target only affected products instead of recalling everything. This alone can justify the investment.

- Enhanced Supply Chain Visibility Know exactly what’s in your inventory and where it came from. Supply chain traceability reduces uncertainty and improves planning. Achieving true inventory visibility requires connecting traceability data across all systems and locations.

- Better Supplier Management Hold suppliers accountable with data. If materials from a particular vendor consistently cause problems, you have documentation to back up conversations.

- Export Readiness International buyers increasingly require traceability as a precondition for doing business. Implementing these systems positions you for global market access.

- GST Compliance Support Traceability systems that track materials through your manufacturing process can support GST compliance by maintaining clear records of inputs and outputs.

- Increased Customer Trust Customers value transparency. Being able to demonstrate where products come from builds confidence and loyalty.

How Do You Implement Traceability in a Manufacturing Process?

Ready to improve traceability in your operations? Here’s a practical roadmap for Indian businesses.

Step 1: Assess Your Current State

Before implementing new systems, understand where you are today. Ask yourself:

- What traceability do we already have?

- Where are the gaps?

- What regulations apply to our industry?

- What do our customers (especially export customers) require?

- What are our biggest quality pain points?

This assessment guides your priorities and investment decisions.

Step 2: Define Your Requirements

Not every manufacturer needs the same level of traceability. Define what “good enough” looks like for your situation.

Consider:

- Batch-level vs. serial-level tracking

- Which components require traceability

- How long records must be retained

- Integration needs with existing systems like Tally or SAP

- Multi-location requirements if you have facilities across different states

Be realistic about your resources and capabilities.

Step 3: Choose the Right Technology

Modern traceability software for manufacturing comes in many forms. Options include:

- Barcode tracking systems for basic identification

- RFID in manufacturing for automated data capture

- Manufacturing Execution Systems (MES) for production floor control

- ERP traceability integration for enterprise-wide visibility

- Cloud-based traceability solutions for accessibility and scalability

India’s growing tech ecosystem means there are now many locally developed options that understand Indian business requirements and offer support in regional languages. For smaller operations, WMS software designed for small businesses in India offers affordable entry points.

The best traceability software for small manufacturers might differ from enterprise-grade solutions. Match technology to your needs and budget.

Step 4: Establish Data Collection Points

Identify where in your process you’ll capture traceability data. Common points include:

- Receiving (incoming materials from suppliers)

- Work-in-process (WIP) tracking stations

- Quality inspection checkpoints

- Final assembly

- Packing and shipping

More collection points mean better visibility but also more complexity. Find the right balance.

Step 5: Train Your Team

Technology only works if people use it correctly. Invest in training at all levels.

India has made significant strides through initiatives like the Skill India Mission and Pradhan Mantri Kaushal Vikas Yojana (PMKVY), which have been instrumental in providing vocational training to millions of youth. Leverage these programmes for upskilling your workforce on traceability systems.

Explain not just how to use the system, but why it matters. When employees understand the purpose, compliance improves.

Step 6: Test and Refine

Start small if possible. Pilot your system at one facility or with a single product line before rolling out broadly.

Use test scenarios to verify the system works:

- Can you trace a product back to its raw materials?

- Can you identify all products made with a specific batch of material?

- Does the data integrate properly with other systems?

Refine based on what you learn.

Technologies Powering Modern Traceability Solutions

Let’s look at the tools that make industrial traceability systems possible for Indian manufacturers.

Barcodes and QR Codes

The simplest and most cost-effective option. Barcode technology for inventory management stores product information in a machine-readable format. Scanning is fast, accurate, and inexpensive.

For even more data capacity, QR codes offer an excellent alternative that can store extensive product information in a compact format. Given India’s widespread smartphone adoption, QR codes can even enable consumer-facing traceability.

Barcoding is particularly accessible for MSMEs. Learn more about small business barcoding to get started with minimal investment.

RFID Technology

RFID technology in manufacturing uses radio waves to identify tagged items. Unlike barcodes, RFID doesn’t require line-of-sight. You can scan multiple items simultaneously.

Higher cost but greater capability. Ideal for high-volume operations or harsh environments where barcodes might be damaged. Learn more about the pros and cons of RFID for inventory management to determine if it’s right for your operation.

Manufacturing Execution Systems (MES)

A Manufacturing Execution System provides real-time visibility into production operations. MES platforms track work orders, machine performance, quality data, and more.

For real-time traceability systems, MES is often the backbone.

Enterprise Resource Planning (ERP)

WMS and ERP integration connects manufacturing data with business systems like finance, procurement, and sales. This enables organization-wide visibility and ensures traceability data flows seamlessly across departments.

Most modern ERP platforms, including SAP, Oracle, and Indian solutions like Tally and Zoho, include traceability modules or integrate with specialized solutions.

Cloud-Based Solutions

Cloud platforms have transformed accessibility for Indian businesses. With reliable internet connectivity now available in most industrial areas, cloud-based traceability solutions offer:

- Lower upfront costs (no servers to purchase)

- Access from anywhere (helpful for multi-location operations)

- Automatic updates and maintenance

- Scalability as your business grows

Common Challenges and How to Overcome Them

Implementing traceability isn’t always smooth. Here are obstacles Indian manufacturers commonly face.

Legacy Systems and Data Silos

Older equipment might not support modern data capture. Different departments might use incompatible systems. Many Indian factories still rely heavily on manual processes and paper records.

Solution: Prioritize integration when selecting new technology. Consider middleware solutions that bridge old and new systems. Start with digital data capture even if full automation isn’t immediately possible. Moving from manual to automated inventory management can be done in phases.

Cost Concerns

Cost of implementing traceability systems varies widely. MSMEs and small manufacturers often worry about ROI, especially with tight margins.

Solution: Start with the highest-risk areas. Calculate potential recall costs without traceability. Look for government schemes and subsidies that support technology adoption in manufacturing. The payback period is often shorter than expected. Avoiding common inventory management mistakes can itself generate significant savings.

Workforce Readiness

Indian manufacturing has historically been dominated by low-skilled labour. Implementing new technology can be challenging when workers lack digital literacy.

Solution: Invest in training. Partner with ITIs or skill development programmes. Start with user-friendly interfaces that require minimal technical knowledge. Build digital capabilities gradually.

Supplier Cooperation

Your traceability is only as good as your supply chain’s. If suppliers can’t provide necessary documentation, you have gaps. Many Indian suppliers, especially smaller ones, may not have robust systems in place.

Solution: Make traceability requirements part of supplier contracts. Help key suppliers improve their capabilities if needed. Consider working with supplier clusters to share best practices.

Infrastructure Limitations

Power fluctuations, inconsistent internet connectivity in some areas, and other infrastructure challenges can disrupt digital systems.

Solution: Choose robust, offline-capable solutions where necessary. Use battery backup for critical scanning stations. Cloud solutions with offline sync capabilities address connectivity issues.

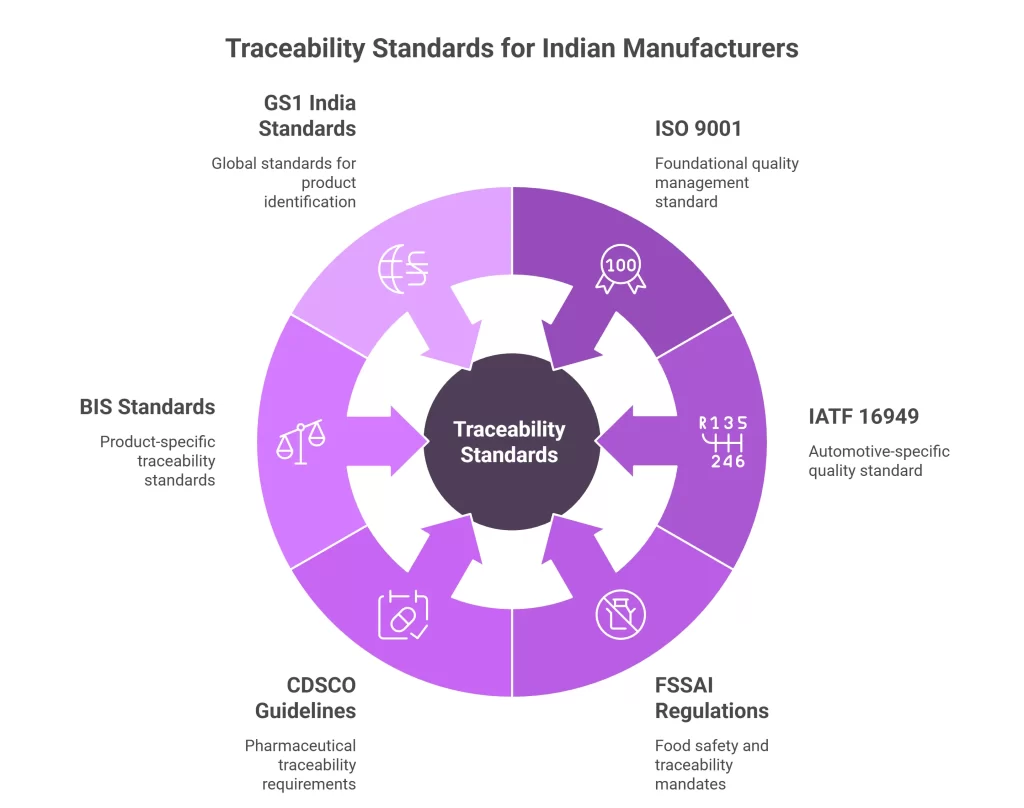

Traceability Standards Relevant for Indian Manufacturers

Several standards guide traceability implementation.

ISO 9001

The foundational quality management standard. ISO 9001 traceability requirements apply to organizations across industries. It mandates identification and traceability “where appropriate.” ISO certification is often a prerequisite for supplying to large companies or exporting.

IATF 16949

Automotive-specific quality standard. Builds on ISO 9001 with additional requirements for automotive traceability standards. Mandatory for automotive supply chain participants in India’s automotive clusters.

FSSAI Regulations

The Food Safety and Standards Authority of India mandates traceability for food businesses. Requirements include maintaining records of suppliers, batch information, and distribution details.

CDSCO Guidelines

The Central Drugs Standard Control Organisation oversees pharmaceutical traceability in India. Track-and-trace requirements are being progressively implemented for domestic and export markets.

BIS Standards

The Bureau of Indian Standards has developed various product-specific standards that include traceability requirements. Compliance is mandatory for products under the Quality Control Orders.

GS1 India Standards

GS1 India promotes global standards for product identification and data exchange. The traceability matrix in manufacturing often follows GS1 guidelines for interoperability, especially important for businesses involved in international trade.

The Future of Manufacturing Traceability in India

Traceability continues to evolve, and India is well-positioned to lead. With its youthful population and growing digital infrastructure, India can effectively leverage technological advancements.

Emerging trends include:

- Blockchain for tamper-proof record keeping

- AI and machine learning for predictive quality analytics

- IoT sensors for automated data capture

- Cloud platforms for supply chain-wide visibility

- Digital thread connecting design, manufacturing, and service

Global investors are increasingly looking at India’s demographics for sustainable growth, concentrating on consumption-driven sectors, manufacturing, infrastructure, and the expanding middle class. Companies with robust traceability systems will be better positioned to attract this investment.

Conclusion

Traceability in manufacturing isn’t just about checking compliance boxes. It’s about running a smarter, more resilient operation that can compete in the global marketplace.

For Indian manufacturers, the stakes are high but so are the opportunities. As Make in India gains momentum and global supply chains increasingly look to India as a manufacturing destination, companies with world-class traceability systems will have a decisive advantage.

From quality control to recall management, from export readiness to customer trust, the benefits are clear. And with India’s growing technology ecosystem, modern cloud-based solutions make implementation easier and more affordable than ever.

Start by assessing your current capabilities. Identify your gaps. Then take incremental steps toward better visibility.

Your customers, regulators, and bottom line will thank you.

Ready to transform your manufacturing operations? Explore how AI-powered tools and modern warehouse management systems can help streamline your traceability systems and unlock insights from your production data. The future of Indian manufacturing is connected, intelligent, and traceable. It’s time to get started.

Frequently Asked Questions (FAQs)

Tracking monitors a product’s current location and status in real time. Traceability provides a complete historical record of where a product has been, what components it contains, and how it was processed. Simply put, tracking tells you where something is now, while traceability tells you its entire journey.

Traceability allows manufacturers to identify exactly which products are affected by a quality issue. Instead of recalling an entire product line, companies can target specific batches or serial numbers. This dramatically reduces recall costs, limits brand damage, and protects consumers more effectively.

A traceability matrix maps relationships between different elements in manufacturing, such as components to suppliers or finished products to raw material batches. It provides a structured view of how everything connects, making it easier to analyse problems and verify compliance during audits.

Yes. Cloud-based solutions reduce upfront costs, and simple barcode systems provide basic capabilities affordably. Many Indian software vendors offer tiered pricing and regional language support. Government schemes under Digital India sometimes provide subsidies for technology adoption.

ERP integration connects production floor data with business systems like finance, procurement, and shipping. It stores traceability records, generates compliance reports, supports GST documentation, and triggers alerts when issues arise. Whether you use SAP, Tally, or Zoho, smooth ERP integration multiplies traceability value.

Kapil Pathak is a Senior Digital Marketing Executive with over four years of experience specializing in the logistics and supply chain industry. His expertise spans digital strategy, search engine optimization (SEO), search engine marketing (SEM), and multi-channel campaign management. He has a proven track record of developing initiatives that increase brand visibility, generate qualified leads, and drive growth for D2C & B2B technology companies.