Imagine this scenario: Your Facebook ad campaign just went viral. Orders are flooding in. Your team is celebrating. But within hours, the excitement turns to panic. You’ve oversold three of your best-selling products. Now you’re facing angry customers, refund requests, and a damaged seller rating on Amazon.

This isn’t a rare nightmare. It happens to Indian ecommerce sellers every single day.

In 2026, India’s ecommerce market has crossed $200 billion, with millions of sellers competing for customer attention. Yet here’s the uncomfortable truth: stock management for ecommerce remains the Achilles’ heel of most online businesses. While sellers invest heavily in marketing and website design, inventory control often runs on outdated spreadsheets and guesswork.

The cost? Lost sales from stockouts. Blocked capital in dead inventory. Marketplace penalties. Customer trust eroding with every cancelled order.

This comprehensive guide covers everything Indian ecommerce sellers need to know about ecommerce inventory management. Whether you’re a small seller processing 100 orders monthly or a growing D2C brand managing multiple warehouses, you’ll find actionable strategies to transform your inventory operations.

We’ll explore real-world challenges, modern solutions, software comparisons, and practical implementation steps. By the end, you’ll have a clear roadmap for taking control of your stock across every sales channel. Let’s get started.

What Is Stock Management for Ecommerce?

Stock management for ecommerce refers to the process of tracking, controlling, and optimizing inventory across all sales channels, warehouses, and product variants. But in 2026, it’s evolved far beyond simple stock counting.

Unlike traditional retail inventory management, ecommerce stock control operates in a fundamentally different environment:

Multi-Channel Complexity

Products sell simultaneously on your website, Amazon, Flipkart, Myntra, Meesho, and potentially social commerce platforms. Each channel needs accurate, real-time stock information.

High SKU Volumes

Ecommerce businesses routinely manage hundreds or thousands of SKUs with multiple variants. A single t-shirt might have 15 size-color combinations, each requiring separate tracking.

Speed Requirements

Popular items sell within minutes during flash sales. Manual updates simply can’t keep pace with modern ecommerce velocity.

Key Components of Modern Ecommerce Stock Management

A robust stock management system for online stores includes:

| Component | Function |

|---|---|

| SKU Management | Unique identifiers for every product variant |

| Real-time Sync | Instant stock updates across all channels |

| Demand Forecasting | AI-powered predictions for future stock needs |

| Reorder Point Alerts | Automated notifications before stockouts |

| Batch Tracking | Managing expiry dates and product lots |

| Multi-warehouse Visibility | Centralized view of distributed inventory |

| GST-compliant Invoicing | Seamless tax compliance for Indian sellers |

Without these elements working together, managing stock for an ecommerce business becomes chaotic. And chaos costs money.

Why Ecommerce Inventory Management Is More Critical Than Ever in India

India’s ecommerce landscape has transformed dramatically. Tier-2 and tier-3 cities now drive significant growth. Social commerce has exploded. Quick commerce promises 10-minute deliveries.

This evolution makes ecommerce inventory management India more complex and more important than ever before.

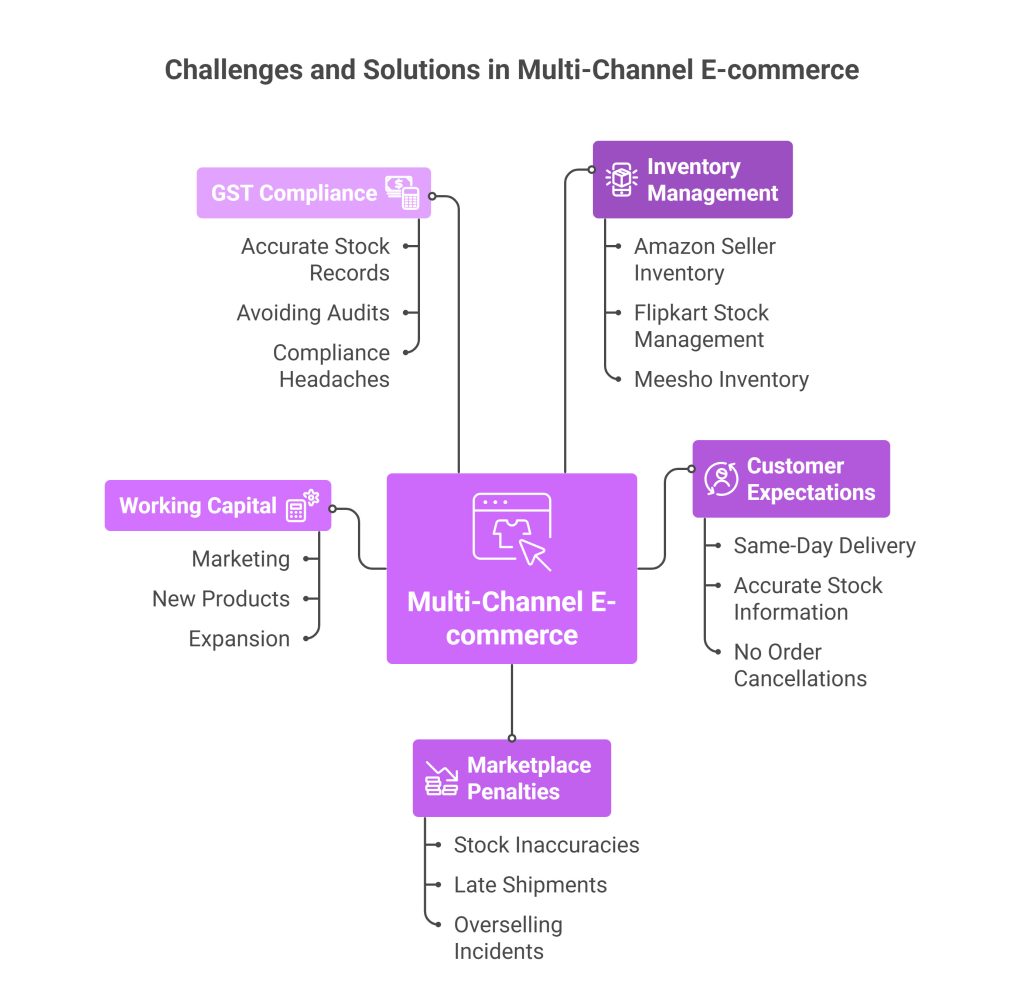

The Multi-Channel Reality

Most successful Indian sellers don’t rely on a single platform anymore. You might sell on Amazon, Flipkart, your own Shopify or WooCommerce store, Meesho for social commerce, and perhaps even offline through pop-up stores.

Managing Amazon seller inventory alongside Flipkart stock management and Meesho inventory without a unified system creates constant fire-fighting.

Customer Expectations Have Skyrocketed

Same-day delivery is becoming standard in metros. Customers expect accurate stock information. They don’t tolerate order cancellations. One bad experience, and they switch to competitors.

Marketplace Penalties Are Real

Platforms like Amazon and Flipkart actively penalize sellers for:

- Stock inaccuracies leading to cancellations

- Late shipments from inventory mismanagement

- Repeated overselling incidents

These penalties affect visibility, Buy Box eligibility, and ultimately revenue.

Working Capital Constraints

For most Indian sellers, capital is precious. Money locked in unsold inventory is money that could fund marketing, new products, or expansion. Effective ecommerce inventory optimization prevents over-investment in slow-moving stock.

GST Compliance Requirements

India’s tax system demands accurate stock records. A GST-compliant inventory software isn’t optional. It’s essential for avoiding audits, penalties, and compliance headaches.

Common Inventory Challenges Indian Ecommerce Businesses Face

Even experienced sellers struggle with inventory control. Let’s examine the pain points that plague businesses across sectors.

1. Overselling and Order Cancellations

Without real-time inventory tracking India, customers place orders for out-of-stock items. The result? Cancellations, refunds, negative reviews, and damaged seller ratings.

This problem multiplies with multi-channel inventory management. A product sells on Amazon, but the website still shows it available. Another order comes in. Now you’re cancelling on two platforms.

2. Dead Stock and Capital Blockage

Unsold inventory silently drains your business. It occupies warehouse space, ties up working capital, and eventually becomes obsolete or expired.

Many sellers don’t realize they have a dead stock problem until cash flow tightens. Proper dead stock management requires visibility into inventory aging and movement patterns.

3. Multi-Warehouse Confusion

As businesses grow, they often establish multiple warehouse locations for faster delivery. But managing stock across locations without centralized warehouse management software India creates:

- Allocation errors

- Wrong warehouse dispatches

- Delivery delays

- Inventory imbalances between locations

4. Returns and Reverse Logistics

India’s ecommerce return rates reach 25-40% in categories like fashion. Every return affects available inventory. Without proper tracking, returned items sit in limbo, neither available for sale nor written off.

5. Seasonal Demand Volatility

Festivals like Diwali, Holi, Raksha Bandhan, and regional celebrations create massive demand spikes. During Diwali 2025, ecommerce platforms reported 300-400% increases in order volumes.

Without accurate demand forecasting, you either overstock (facing storage costs and potential dead stock) or understock (losing sales to competitors).

6. Fragmented Logistics Infrastructure

Despite improvements, India’s logistics network has gaps. Managing Indian warehouse management across tier-1 cities and smaller towns requires adaptable systems that account for varying delivery timelines and infrastructure limitations.

How Modern Stock Management Systems Solve These Problems

A dedicated ecommerce stock management system addresses each challenge systematically. Here’s how:

Centralized Dashboard for Complete Visibility

Monitor inventory across all channels, warehouses, and product variants in one place. No more switching between Amazon Seller Central, Flipkart dashboard, and your website backend.

Automatic Stock Synchronization

When a product sells anywhere, stock levels update everywhere in real-time. This prevents overselling, eliminates manual update delays, and ensures customers always see accurate availability.

Smart Multi-Warehouse Allocation

Modern systems automatically route orders to the optimal warehouse based on:

- Customer location

- Stock availability

- Delivery speed requirements

- Warehouse capacity

This improves delivery times and balances inventory across locations.

Batch and Expiry Management

Especially critical for FMCG, beauty, and perishable products. The system tracks batch numbers, expiry dates, and ensures FIFO/LIFO (First-In-First-Out / Last-In-First-Out) or FEFO (First-Expiry-First-Out) allocation automatically.

Predictive Reorder Intelligence

Instead of reactive ordering when stock runs out, modern systems analyze sales velocity and historical patterns to generate reorder point alerts before problems occur.

Returns Integration

Automated tracking of return status, quality checks, and restocking ensures returned items get back into saleable inventory quickly.

Step-by-Step: Setting Up Stock Management for Your Ecommerce Store in India

Ready to transform your inventory operations? Here’s a practical implementation roadmap.

Step 1: Audit Your Current Inventory

Before implementing any system, understand your starting point. Conduct a physical inventory audit and compare it with your digital records.

You’ll likely discover discrepancies. Missing items. Phantom stock that exists in systems but not on shelves. Products in the wrong locations.

Pro tip: Use barcode scanning to speed up counting and reduce human error. Basic barcode scanners cost under ₹5,000 and dramatically improve accuracy.

Step 2: Establish Proper SKU Architecture

Every product needs a unique identifier. Effective SKU management helps you track variants efficiently.

Create a logical naming convention your team can understand:

CATEGORY-BRAND-VARIANT-SIZE-SEQUENCE

Example: TSHIRT-LEVIS-BLU-M-001

This structure should accommodate:

- Product category

- Brand or collection

- Color/variant

- Size

- Batch or sequence number

Step 3: Calculate Reorder Points and Safety Stock

Don’t wait until you’re out of stock to reorder. Calculate your reorder point for each product using this formula:

Reorder Point = (Average Daily Sales × Lead Time) + Safety Stock

For example:

- Average daily sales: 10 units

- Supplier lead time: 7 days

- Desired safety stock: 20 units

- Reorder Point: (10 × 7) + 20 = 90 units

When stock hits 90 units, you trigger a reorder. The safety stock level provides buffer against demand spikes or supplier delays.

Step 4: Select the Right Software

This decision significantly impacts your operations. We’ll cover specific recommendations in the next section, but evaluate based on:

- Integration with your sales channels

- GST compliance features

- Multi-warehouse support

- Pricing relative to your order volume

- Implementation complexity

Step 5: Integrate All Sales Channels

Your inventory system must connect to every platform where you sell. This includes:

- Stock management for Shopify India or WooCommerce

- Amazon India Seller Central

- Flipkart Seller Hub

- Meesho supplier dashboard

- Any POS systems for offline sales

Real-time sync across all channels is non-negotiable for preventing overselling.

Step 6: Train Your Team Thoroughly

The best software fails if your team doesn’t use it correctly. Invest time in training:

- Warehouse staff on receiving and dispatch procedures

- Operations managers on dashboard monitoring

- Customer service on checking real-time availability

Document standard operating procedures and update them as processes evolve.

Step 7: Implement Regular Audit Cycles

Even with automated systems, physical verification matters. Establish cycle counting procedures, conducting partial inventory checks regularly rather than infrequent full audits.

Monthly counts for fast-moving items and quarterly counts for slower inventory maintain accuracy without disrupting operations.

Real-World Scenarios: Industry-Specific Stock Management Challenges

Different product categories face unique inventory challenges. Here’s how proper stock management addresses each:

D2C Fashion Brand

Challenges:

- High return rates (30-40%)

- Multiple size and color variants per style

- Seasonal collections with limited shelf life

- Size-specific demand patterns

Solutions:

- Real-time sync prevents overselling popular sizes

- Automated allocation blocks inventory for pending orders

- Returns tracking enables quick restocking of saleable items

- Variant-level analytics identify bestselling combinations

Electronics Seller

Challenges:

- Serial number tracking for warranty purposes

- High product values requiring precise control

- Technical specifications affecting returns handling

- Price volatility impacting inventory valuation

Solutions:

- Serial number capture at receiving and dispatch

- Strict stock locking for order fulfilment

- Quality check workflows for returns

- Accurate inventory valuation for financial reporting

FMCG and Perishables Seller

Challenges:

- Expiry date management

- Batch-level tracking for recalls

- FIFO/FEFO compliance requirements

- Higher stockout risk for essential items

Solutions:

- Automated expiry alerts before products become unsellable

- Batch tracking enables quick recall response

- System-enforced FIFO/FEFO picking

- Demand-based reorder triggers prevent stockouts

Multi-Brand Distributor

Challenges:

- Thousands of SKUs across categories

- Multiple supplier relationships

- Complex pricing by brand and channel

- Warehouse space optimization

Solutions:

- Scalable SKU management without performance degradation

- Supplier-wise purchase order management

- Channel-specific pricing rules

- Location-wise stock organization

When Should You Switch from Spreadsheets to Stock Management Software?

Many Indian ecommerce sellers continue using Excel far beyond the point where it becomes risky. The problem is that inventory issues often remain hidden until significant damage occurs to revenue, ratings, and customer relationships.

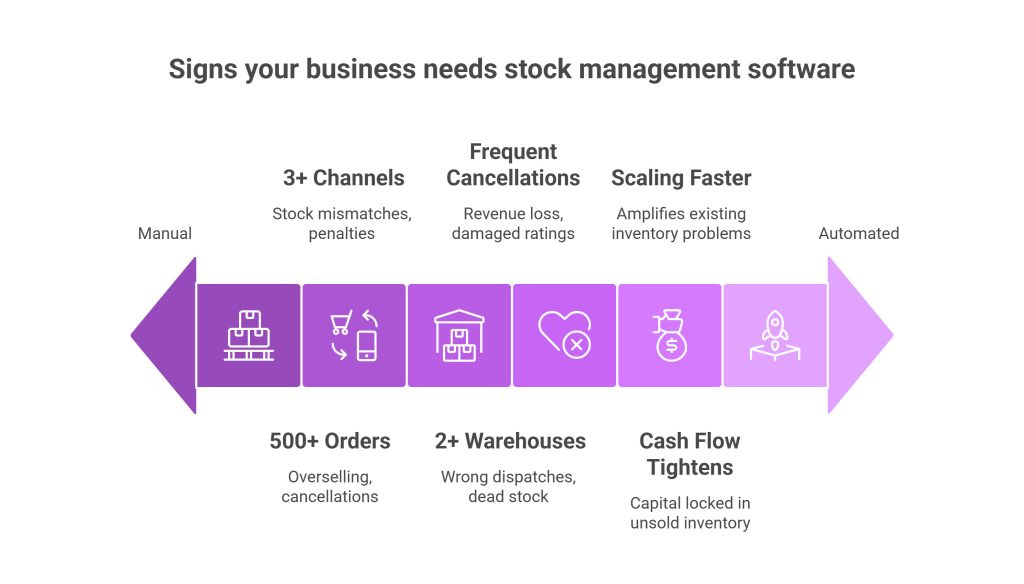

If your business shows any of these signs, manual inventory control is likely limiting your growth:

1. You Process 500+ Orders Monthly

At this volume, inventory movement happens too fast for manual updates. Multiple orders get packed simultaneously, human errors increase, and stock updates lag behind actual sales.

The risk: Overselling becomes common, leading to cancellations and marketplace penalties.

2. You Sell on 3+ Sales Channels

Managing inventory across your website, Amazon, Flipkart, and social commerce manually creates stock mismatches between platforms.

The risk: Channel-specific overselling, inconsistent availability, and marketplace performance penalties.

3. You Operate 2+ Warehouse Locations

Split inventory means complex order allocation decisions. Which warehouse fulfills which order?

The risk: Wrong warehouse dispatches, increased delivery times, and silent dead stock buildup in underutilized locations.

4. You Experience Frequent Cancellations or RTOs

Inventory inaccuracies cause customer cancellations and return-to-origin (RTO) shipments.

The risk: Direct revenue loss plus damaged seller ratings affecting future visibility.

5. Cash Flow Tightens Despite Growing Sales

If sales increase but cash remains tight, inventory might be the culprit. Slow-moving SKUs, expired products, and excess stock silently consume working capital.

The risk: Growth opportunities missed due to capital locked in unsold inventory.

6. You’re Scaling Faster Than Processes Can Handle

What worked at 100 orders monthly fails at 1,000+. If marketing and sales outpace operational capabilities, inventory problems multiply.

The risk: Scaling without proper inventory control amplifies every existing problem.

Key Features to Look for in Ecommerce Stock Management Software

When evaluating options, prioritize these capabilities:

Real-Time Inventory Synchronization

Non-negotiable for multi-channel selling. Stock levels must update instantly across all platforms when sales, returns, or adjustments occur.

Multi-Warehouse Support

As you grow, you’ll likely need multiple storage locations. The software should handle location-wise visibility, smart allocation, and inter-warehouse transfers.

Batch and Expiry Tracking

Essential for FMCG, beauty, supplements, and any products with shelf life. The system should enforce FIFO/LIFO or FEFO automatically.

Marketplace and Platform Integrations

Check for native integrations with your sales channels. Inventory management API integration India capabilities enable custom connections where native integrations don’t exist.

GST-Compliant Features

GST-compliant inventory software should generate proper invoices, maintain required records, and integrate with accounting systems like Tally.

Reporting and Analytics

Beyond basic stock counts, look for:

- Stock turnover ratio analysis

- Days sales of inventory (DSI) tracking

- Dead stock identification

- Channel-wise performance metrics

- Inventory carrying cost calculations

Mobile Access

Warehouse teams need mobile capabilities for receiving, picking, and counting. Mobile apps or responsive dashboards enable operations anywhere.

Stock Management for Multi-Channel Selling in India

Selling across multiple platforms requires careful inventory orchestration. Here’s how to manage multi-channel inventory management effectively:

Centralize Your Master Stock

Maintain one source of truth for inventory. All channels should pull from and update this central pool. Avoid maintaining separate stock counts per platform.

Implement Channel-Specific Allocation

Not all channels perform equally. Analyze sales velocity per platform and consider:

- Reserving stock for high-performing channels

- Setting different buffer levels by platform

- Adjusting allocation during promotional periods

Handle Returns Systematically

Returns from Amazon, Flipkart, and direct orders arrive at different times with different processes. Establish standardized workflows for:

- Receiving and quality inspection

- Restocking decisions

- Defective inventory segregation

- Write-off procedures

Monitor Platform-Specific Metrics

Track fill rate and fulfilment performance for each channel separately. This helps identify which platforms need operational attention.

Manage Promotional Inventory

Flash sales and deals require inventory reservations. Your system should:

- Lock inventory for upcoming promotions

- Prevent accidental overselling during high-traffic events

- Automatically release unsold promotional stock

Preventing Stockouts and Managing Dead Stock

Balance is everything in inventory management. Too little stock means lost sales. Too much means blocked capital. Here’s how to find equilibrium:

Strategies for Stockout Prevention

1. Implement Automated Reorder Alerts

Configure your inventory software to notify when stock approaches reorder points. Advanced systems generate purchase orders automatically.

2. Build Strategic Supplier Relationships

Reliable suppliers with shorter lead times reduce your need for high safety stock. Establish backup suppliers for critical products.

3. Use Demand Forecasting Intelligently

Modern inventory management software India 2026 includes AI-powered forecasting. Feed it historical data, seasonality patterns, and market trends for better predictions.

4. Monitor Early Warning Indicators

Track metrics like sell-through rate and stock coverage days. Declining coverage signals potential stockout risks.

Strategies for Dead Stock Management

1. Identify Slow-Moving Inventory Early

Aging reports highlight products sitting too long. Set thresholds, perhaps 90 days of no movement, to flag items for review.

2. Take Action Before Value Erodes

Options for slow-moving stock include:

- Promotional pricing

- Bundle with faster-moving items

- Marketplace liquidation channels

- Donation for tax benefits

3. Analyze Root Causes

Why did stock become dead? Poor demand forecasting? Trend shifts? Quality issues? Understanding causes prevents repetition.

4. Implement FIFO/FEFO Strictly

System-enforced picking sequences ensure older stock moves first, reducing obsolescence risk.

Key Inventory Metrics Every Ecommerce Seller Should Track

Data drives decisions. Monitor these metrics to understand your inventory health:

Stock Turnover Ratio

How many times you sell and replace inventory in a period. Higher turnover generally indicates efficient stock management.

Formula: Cost of Goods Sold ÷ Average Inventory Value

Example: ₹50,00,000 COGS ÷ ₹10,00,000 Average Inventory = 5 turns per year

Days Sales of Inventory (DSI)

How many days, on average, inventory sits before selling. Lower DSI means faster-moving stock.

Formula: (Average Inventory ÷ Cost of Goods Sold) × 365

Benchmark: Fashion typically aims for 60-90 days; electronics 30-60 days.

Fill Rate

Percentage of customer orders fulfilled completely from available stock. This directly impacts customer satisfaction.

Target: 95%+ for healthy operations.

Inventory Carrying Cost

Total cost of holding inventory, including storage, insurance, depreciation, and opportunity cost of capital.

Typical Range: 20-30% of inventory value annually.

Understanding this cost helps justify investment in better inventory management.

Sell-Through Rate

Percentage of received inventory sold within a specific period.

Formula: Units Sold ÷ Units Received × 100

Low sell-through signals potential overbuying or demand miscalculation.

Ecommerce vs. Traditional Inventory Management: Key Differences

Understanding how ecommerce stock control differs from traditional retail helps frame your approach:

| Aspect | Ecommerce Inventory | Traditional Retail |

|---|---|---|

| Update Frequency | Real-time, continuous | Periodic, manual |

| Channel Scope | Multiple platforms synced | Single store focus |

| Order Allocation | Automated, rule-based | Manual assignment |

| Reorder Approach | Predictive, data-driven | Reactive, experience-based |

| Geographic Spread | Multiple warehouses, national | Centralized or regional |

| SKU Complexity | Thousands with variants | Hundreds, curated |

| Customer Expectations | Instant confirmation, fast delivery | In-store availability |

Ecommerce demands faster, smarter, and more integrated inventory solutions than traditional systems can provide.

Future Trends in Ecommerce Stock Control for India

What’s next for ecommerce stock control India? These trends are shaping 2026 and beyond:

AI-Powered Demand Forecasting

Machine learning algorithms now incorporate weather patterns, social media trends, competitor pricing, and macroeconomic indicators for unprecedented prediction accuracy.

Warehouse Automation

Robotics, automated picking systems, and smart shelving are becoming affordable for mid-sized operations. Warehouse management software India increasingly supports these technologies.

Hyperlocal Fulfillment Networks

Dark stores and micro-fulfillment centers enable 10-minute deliveries in metros. Managing inventory across dozens of small locations requires sophisticated distributed inventory systems.

Sustainability-Driven Inventory

Consumers care about environmental impact. Better inventory management reduces waste from unsold goods, excessive packaging, and unnecessary transportation.

Blockchain for Supply Chain Transparency

Track products from manufacturer to customer with immutable records. Particularly valuable for authenticity verification and recall management.

Voice and IoT Integration

Smart warehouse devices and voice-commanded inventory checks are entering mainstream adoption.

Conclusion

In 2026, stock management for ecommerce is no longer a back-end operational task. It’s a direct growth driver that affects customer satisfaction, marketplace performance, cash flow, and profitability.

The Indian ecommerce landscape is more competitive than ever. Customers expect accuracy. Marketplaces enforce strict SLAs. Margins remain thin. In this environment, inventory management becomes a genuine competitive advantage.

Manual spreadsheets and disconnected systems simply cannot keep pace with modern requirements. They silently cause revenue loss through overselling, cancellations, dead stock, blocked working capital, and marketplace penalties.

A modern ecommerce inventory management system provides real-time visibility, accurate order allocation, batch and expiry control, predictive reordering, and centralized inventory across all channels. It helps you scale profitably without losing control.

Your next steps:

- Audit your current inventory accuracy

- Identify which challenges from this guide affect your business

- Evaluate software options based on your scale and needs

- Implement systematically with proper team training

- Monitor metrics and continuously improve

Ready to transform your inventory operations? Explore AI-powered inventory management tools that can take your ecommerce business to the next level. The technology exists. The competitive pressure demands action. The question is: will you make the move?

Frequently Asked Questions (FAQs)

The process of tracking and optimizing inventory across all online channels and warehouses in real time. It prevents overselling, reduces cancellations, and improves fulfilment efficiency—directly impacting customer satisfaction and profitability.

Inventory management tracks stock levels, reorder points, and demand forecasting across channels. Warehouse management handles physical operations like receiving, storage, picking, packing, and shipping. Many modern solutions integrate both.

The best software depends on your business needs. Popular options include Unicommerce, Zoho Inventory, and Vinculum for multi-channel sellers. However, for businesses prioritizing warehouse operations and fulfilment efficiency, OmnielabWMS stands out with advanced picking workflows, location-level tracking, and seamless marketplace integrations designed specifically for Indian ecommerce operations.

Key signs: 500+ orders/month, selling on 3+ channels, multiple warehouses, frequent cancellations/RTOs, or stock discrepancies. At this stage, software efficiency gains and error reduction justify the cost.

Use demand forecasting based on historical sales and seasonality. Calculate reorder points: (Avg Daily Sales × Lead Time) + Safety Stock. Build reliable supplier relationships for faster restocking.

Kapil Pathak is a Senior Digital Marketing Executive with over four years of experience specializing in the logistics and supply chain industry. His expertise spans digital strategy, search engine optimization (SEO), search engine marketing (SEM), and multi-channel campaign management. He has a proven track record of developing initiatives that increase brand visibility, generate qualified leads, and drive growth for D2C & B2B technology companies.