If you’re managing warehouse operations in India, you’ve likely already implemented some form of WMS traceability. But here’s the question that keeps many supply chain professionals up at night: Are you using the right level of traceability?

With FSSAI tightening regulations, pharmaceutical export requirements becoming stricter, and e-commerce giants demanding end-to-end visibility from their 3PL partners, the choice between unit-level traceability and batch-level traceability has never been more critical.

This guide skips the basics you already know and dives straight into the practical considerations—cost implications, compliance requirements specific to Indian regulations, implementation challenges, and decision frameworks that will help you optimize your warehouse traceability system.

Whether you’re considering upgrading from batch to unit-level traceability or evaluating a WMS hybrid lot and serial tracking approach, this guide provides the strategic insights you need.

Unit-Level vs. Batch-Level: A Strategic Comparison

Let’s cut straight to what matters. Here’s how these two approaches compare across critical business dimensions:

Recall Management: The True Cost Differentiator

The real difference between serial number traceability and lot-level traceability becomes painfully clear during recalls.

Consider this scenario: A pharmaceutical distributor in Hyderabad discovers contamination affecting products from a specific manufacturing run.With unit-level traceability, you can isolate only the 47 affected units, keeping direct recall costs around ₹2.3 lakhs with minimal customer disruption. Regulatory response happens within 4 hours, and brand reputation damage stays contained.

With batch-level traceability, you’re forced to recall the entire batch of 5,000 units. Direct costs balloon to ₹18.7 lakhs, customers face significant stockouts, and regulatory response stretches beyond 12 hours—causing widespread brand damage.

For high-value or regulated products, WMS recall management capabilities at the unit level can deliver ROI within a single incident. As tracking experts note, with a unit-level traceability system, you can authenticate products at every step and reduce recall size significantly by isolating only affected batches or products

Operational Throughput Impact

Here’s what many WMS vendors won’t tell you upfront—granular product tracking affects your warehouse velocity:Unit-level scanning requirements:

- Average scan time: 3-5 seconds per item

- Database write operations: One per unit

- Label printing: Individual labels required

- Error correction: Complex (must locate specific serial)

Batch-level scanning requirements:

- Average scan time: 3-5 seconds per batch (multiple items)

- Database write operations: One per batch

- Label printing: Batch labels only

- Error correction: Simpler (batch-level adjustments)

For high-volume operations like FMCG distribution centers handling 50,000+ SKUs daily, this throughput difference translates to significant labor cost variations.

Data Storage and Infrastructure Demands

Your cloud WMS infrastructure requirements scale dramatically with unit-level tracking:

| Metric | Batch-Level | Unit-Level |

|---|---|---|

| Database records per 10,000 items | 50-200 (batch records) | 10,000+ (individual records) |

| Annual storage growth | Moderate | Aggressive |

| API transaction volume | Standard | 10-50x higher |

| Backup/recovery complexity | Manageable | Significant |

Indian businesses using SaaS WMS solutions should factor these infrastructure costs into their total cost of ownership calculations. Choosing the right warehouse management solution from the start helps avoid costly migrations later.

India-Specific Regulatory Landscape

Pharmaceutical Sector: Serialization Mandates

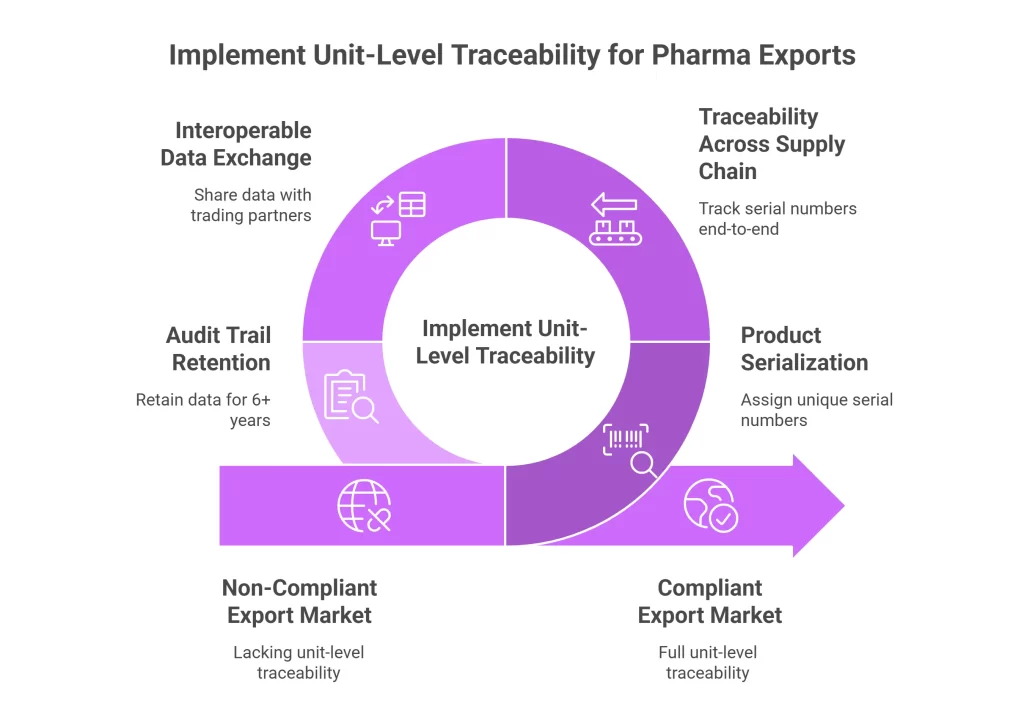

India’s pharmaceutical export market demands strict compliance tracking. If you’re distributing products to:

US Markets (FDA/DSCSA):

- Full product serialization at unit level mandatory by 2025

- Serial number traceability across the entire supply chain

- Interoperable data exchange with trading partners

- Audit trail retention for 6+ years

EU Markets (FMD):

- Unique identifier per saleable unit

- Tamper-evident packaging verification

- End-to-end traceability from manufacturer to dispenser

Domestic Distribution:

- Current focus on batch-level tracking under Drug Track and Trace System

- Serialization pilots underway for select categories

- Expect tighter requirements by 2026-27

Strategic Recommendation: Export-oriented pharmaceutical warehouses should implement unit-level traceability now. A robust pharmaceutical warehouse management system provides the compliance foundation you need.

Food and Beverage: FSSAI Requirements

FSSAI’s Food Safety and Standards (Packaging and Labelling) Regulations require:

- Lot number or batch number on all packaged foods

- Manufacturing date and best-before tracking

- FEFO (First Expired First Out) compliance

- Recall capability within 24-48 hours

For most food distribution operations, batch traceability in warehouse systems satisfies current FSSAI requirements. Implementing proper batch and expiry tracking in FMCG operations ensures compliance while optimizing inventory rotation.

Electronics and IT Hardware

BIS (Bureau of Indian Standards) requirements and extended warranty tracking are pushing electronics distributors toward item-level traceability:

- Serial number tracking for warranty validation

- IMEI tracking for mobile devices (mandatory)

- Individual unit tracking for high-value components

- Integration with manufacturer warranty portals

For e-commerce operations, implementing inventory serialization significantly reduces return fraud and improves customer service efficiency.

Implementation Decision Framework

Rather than asking “which is better,” ask these strategic questions:

Question 1: What’s Your Recall Risk Profile?

Calculate your recall exposure score:

Recall Exposure = (Average Batch Size) × (Product Value) × (Recall Probability) × (Brand Impact Multiplier)

High recall exposure indicators:

- Batch sizes exceeding 10,000 units

- Product value above ₹500 per unit

- Operating in regulated industries

- Strong brand equity at stake

If your recall exposure score is high, the premium for unit-level traceability is likely justified.

Question 2: What’s Your Customer Mandate Reality?

Map your customer requirements:

| Customer Type | Typical Requirement | Flexibility |

|---|---|---|

| Large e-commerce platforms | Moving toward unit-level for electronics | Low |

| Pharmaceutical distributors | Unit-level for exports, batch for domestic | Medium |

| FMCG retailers | Batch-level acceptable | High |

| Quick commerce | Batch-level with strong FEFO | High |

| 3PL contracts | Varies by client | Contract-dependent |

3PL warehouse traceability requirements are increasingly contract-specific. Understanding common 3PL WMS mistakes helps you avoid costly implementation errors.

Question 3: What’s Your Technology Readiness?

Assess your current infrastructure against unit-level requirements:Minimum requirements for unit-level tracking:

- High-speed barcode scanning (sub-second reads)

- Reliable network connectivity (99.5%+ uptime)

- Sufficient WMS database capacity

- Staff training infrastructure

- Label printing capabilities (individual labels)

- RFID infrastructure (recommended for high-value items)

If you’re checking fewer than 4 boxes, consider a phased approach or batch-level implementation first.

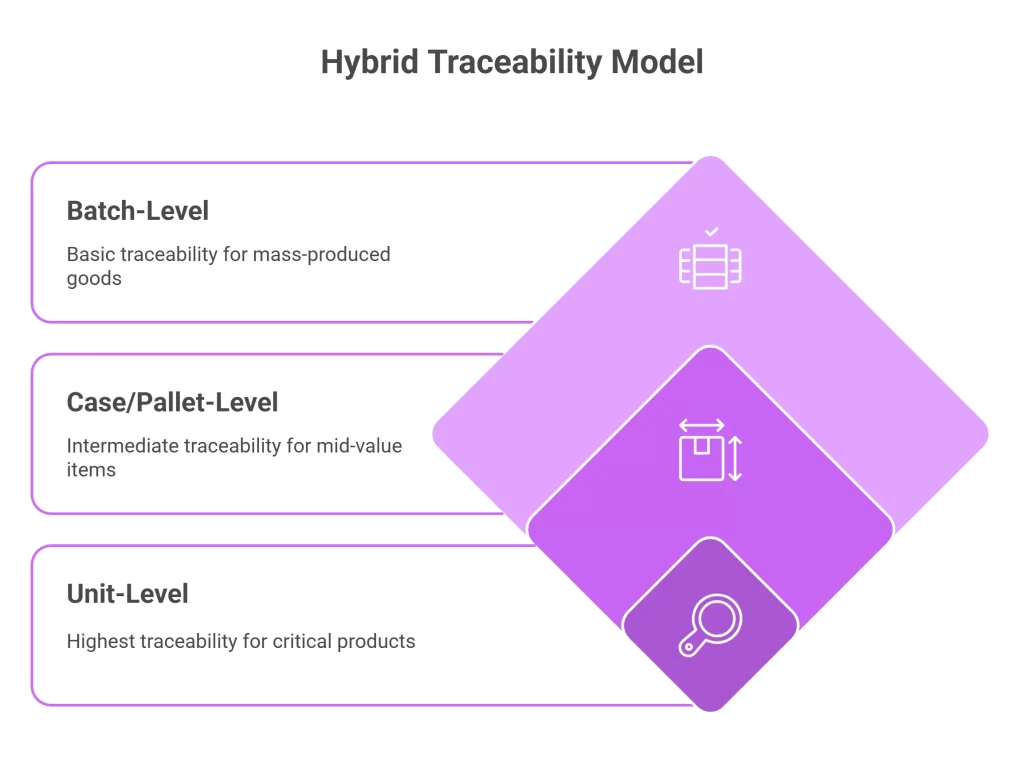

Hybrid Traceability: The Practical Indian Approach

A hybrid approach requires robust ERP integration and API integration capabilities. Understanding WMS integration types and benefits ensures seamless data flow across your technology stack.

Implementing a Tiered Traceability Model

Tier 1 (Unit-Level):

- Pharmaceuticals for export

- High-value electronics (>₹25,000)

- Medical devices

- Serialization-mandated products

Tier 2 (Case/Pallet-Level):

- Mid-value electronics

- Premium cosmetics

- Automotive components

- B2B industrial products

Tier 3 (Batch-Level):

- FMCG products

- Food and beverage

- General merchandise

- Low-value consumables

WMS Configuration for Hybrid Approach

Your traceability-enabled WMS should support:

- Product-level traceability rules: Configure tracking level per SKU category

- Dynamic scanning workflows: Prompt for serial numbers only when required

- Flexible label generation: Batch or serial labels based on product type

- Unified reporting: Consolidated audit trail across all traceability levels

- Client-specific configurations: Essential for 3PL operations

Technology Stack Recommendations for Indian Operations

Barcode vs. RFID: Making the Right Choice

| Factor | Barcode | RFID |

|---|---|---|

| Initial cost per item | ₹0.50-2 | ₹15-50 |

| Read speed | Line-of-sight required | Bulk reads possible |

| Environmental durability | Moderate | High |

| Indian vendor availability | Excellent | Growing |

| Best for | Standard warehouse ops | High-value, high-volume |

- High-value inventory requiring automated cycle counting

- Cold chain operations needing IoT sensors integration

- Dock door portals for bulk receiving/shipping verification

Practical recommendation: Most Indian warehouses achieve excellent ROI with 2D barcodes and QR codes using GS1 standards. Implementing barcode technology for inventory management delivers immediate accuracy improvements.

Before investing in RFID, understand the complete pros and cons of RFID for inventory management to make informed decisions.

Mobile Scanning Hardware Selection

For Indian warehouse environments, prioritize:

- Ruggedized devices: Dust and humidity resistance essential

- Extended battery life: 10+ hours for single-shift operations

- Connectivity options: Wi-Fi 6 with offline capability

- Local service availability: Critical for minimizing downtime

- TCO over 3-year lifecycle: Include repair and replacement costs

Leading options in the Indian market include Zebra, Honeywell, and emerging Indian OEMs offering competitive alternatives for cost-sensitive deployments.

ROI Calculation Variables

Quantifiable benefits of unit-level tracking:

- Recall cost reduction: Calculate based on historical recall frequency

- Inventory accuracy improvement: Typically 15-25% shrinkage reduction

- Warranty claim reduction: For electronics, often 10-20% improvement

- Premium contract eligibility: Access to clients requiring serialization

Quantifiable benefits of batch-level tracking:

- Lower operational costs: 40-60% savings vs. unit-level

- Faster implementation: Typically 3-6 months vs. 6-12 months

- Simpler training requirements: 30-50% less training investment

- Lower technology risk: Proven, mature implementations

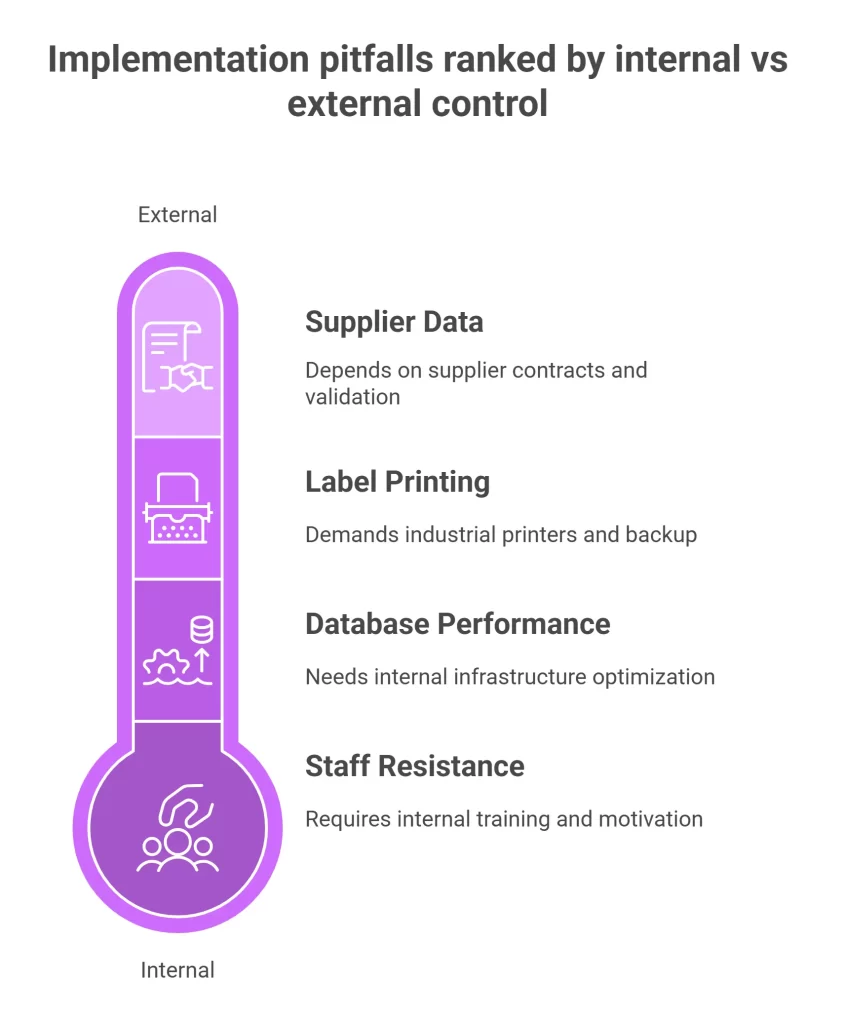

Common Implementation Pitfalls (And How to Avoid Them)

Pitfall 1: Underestimating Label Printing Logistics

The problem: Unit-level traceability requires individual labels for every item. Printing 50,000 labels daily is a different challenge than printing 500 batch labels.The solution:

- Invest in industrial-grade label printers (2-4 units per warehouse zone)

- Implement print-on-demand workflows integrated with WMS receiving

- Plan for backup equipment and label stock inventory

- Consider pre-labeled products from suppliers where possible

Pitfall 2: Database Performance Degradation

The problem: Transaction volumes increase 50-100x with unit-level tracking, causing system slowdowns.The solution:

- Right-size your cloud WMS infrastructure from day one

- Implement database archiving policies (move historical data to cold storage)

- Optimize API integration calls to minimize redundant transactions

- Schedule cycle counting and reporting during off-peak hours

Pitfall 3: Staff Resistance and Training Gaps

The problem: Warehouse teams accustomed to batch processes struggle with serial scanning discipline.The solution:

- Phased rollout: Start with one zone or product category

- Gamification: Track individual accuracy rates with incentives

- Exception handling: Clear workflows for scan failures or missing labels

- Supervisor training: Ensure floor leadership can troubleshoot common issues

Pitfall 4: Supplier Data Quality Issues

The problem: Upstream serial number traceability fails because suppliers provide inconsistent or missing data.The solution:

- Include traceability requirements in supplier contracts

- Implement receiving validation rules in WMS

- Create supplier scorecards tracking data quality

- Build quarantine workflows for non-compliant shipments

Future-Proofing Your Traceability Investment

Emerging Trends to Monitor

Blockchain-enabled traceability: While still maturing in India, blockchain pilots for supply chain visibility are underway in pharmaceuticals and agriculture. Your WMS architecture should support future API integration with distributed ledger platforms.

AI-powered anomaly detection: Modern warehouse traceability systems are incorporating machine learning to identify suspicious patterns—potential counterfeits, diversion, or quality issues—from traceability data streams.Consumer-facing transparency: Brands are increasingly exposing traceability data to end consumers via QR codes. Your unit-level identification strategy should consider customer-facing applications.

Building Migration Paths

If implementing batch-level today with plans to upgrade later:

- Use GS1 standards for barcode formats (ensures serialization compatibility)

- Choose WMS platforms that support both lot control and serial control

- Standardize label placement and sizing for future serial labels

- Document your batch logic clearly for future serial transition mapping

Conclusion: Making Your Traceability Decision

The unit-level traceability vs. batch-level traceability decision isn’t about technology—it’s about aligning your traceability investment with genuine business value drivers.For most Indian operations, the path forward involves:

- Honest assessment of regulatory, customer, and operational requirements

- Hybrid architectures that apply appropriate granularity by product segment

- Phased implementation that builds capabilities without operational disruption

- Continuous optimization as requirements evolve

The warehouses winning in India’s competitive landscape aren’t necessarily those with the most advanced traceability—they’re the ones with the right traceability for their business context.

Ready to optimize your traceability strategy? Explore Omneelab’s WMS solutions that offer intelligent traceability configuration, seamless integration capabilities, and the flexibility to implement precisely the traceability architecture your operations need.

Frequently Asked Questions (FAQs)

Calculate ROI using recall cost exposure, premium contract revenue opportunity, and shrinkage reduction potential. If annual recall risk exceeds ₹50 lakhs or you’re losing contracts worth ₹1 crore+ due to missing serial number tracking, payback typically occurs within 18-24 months.

Yes, most modern cloud WMS platforms support hybrid lot and serial tracking through configuration. Key requirements include product-level traceability rules, API integration capabilities, and flexible barcode scanning configurations.

Current FSSAI regulations accept batch-level traceability for most food categories, requiring lot number tracking and FEFO rotation. Consider unit-level traceability only for high-risk categories, export-oriented businesses, or blockchain-based consumer transparency initiatives.

3PL WMS traceability requires client-specific configuration profiles supporting per-client rules, configurable workflows, and segregated audit trail reporting. Leading Indian 3PLs charge premium rates for clients requiring unit-level traceability.

Prioritize database infrastructure (unit-level generates 50-100x more records), barcode scanning hardware, industrial label printing capacity, and ERP integration API optimization. Budget 40-60% of implementation costs for infrastructure.

Kapil Pathak is a Senior Digital Marketing Executive with over four years of experience specializing in the logistics and supply chain industry. His expertise spans digital strategy, search engine optimization (SEO), search engine marketing (SEM), and multi-channel campaign management. He has a proven track record of developing initiatives that increase brand visibility, generate qualified leads, and drive growth for D2C & B2B technology companies.