If you’re managing warehouse operations for a food and beverage company in India, you already know the stakes. Thin margins, perishable inventory, demanding retailers, and FSSAI breathing down your neck—it’s a constant balancing act.

You’ve probably outgrown spreadsheets. Maybe you’re running a legacy system that can’t keep up. Or perhaps you’re evaluating whether your current WMS for food and beverage industry India actually delivers what the vendor promised.

Here’s the reality: most generic warehouse management systems fail F&B operations. They weren’t built for the complexity of expiry management, multi-temperature zones, or the traceability demands that come with food safety regulations.

This guide cuts through the noise. We’ll focus on five specific capabilities that separate an adequate warehouse management system for F&B companies from one that actually drives operational excellence. We’ll also show you why solutions like WMS are becoming the go-to choice for Indian F&B businesses looking for purpose-built capabilities. No basics. No fluff. Just actionable insights for professionals who need to make smart decisions. Let’s get into it.

1. Advanced Batch Tracking with Granular Traceability

You already understand batch tracking. The question is: how sophisticated does your batch tracking and traceability need to be?

For Indian F&B operations, surface-level lot tracking won’t cut it. Here’s what advanced batch management actually looks like:

Multi-Attribute Batch Identification

Your WMS should capture and query batches across multiple dimensions simultaneously:

- Manufacturing date and time (not just date)

- Production line or facility identifier

- Supplier lot reference

- Quality grade classification

- Country of origin (critical for imports)

- Certifications (organic, non-GMO, Halal, etc.)

This granularity matters when you’re dealing with ingredient recalls. A food traceability software India solution should let you trace not just finished goods, but component ingredients back to their source batches. For a deeper dive into this critical capability, explore our guide on batch and expiry tracking in FMCG.

Bi-Directional Traceability

Forward traceability tells you where a batch went. Backward traceability tells you what went into it.

For complex products—think ready-to-eat meals or blended beverages—you need both. If a spice supplier reports contamination, your WMS should instantly identify:

- Which production batches used that spice lot

- Which finished goods contain those production batches

- Which customers received those finished goods

- Current inventory still in warehouse

Omneelab WMS excels here with its real-time inventory oversight and advanced analytics capabilities . The platform’s location intelligence ensures every batch movement is tracked and queryable within seconds—critical when recall timelines are measured in hours, not days.

Nested Batch Hierarchies

Raw material batch → Production batch → Packaging batch → Pallet batch

Your WMS should maintain these relationships automatically. When a retailer scans a consumer unit, the entire lineage should be retrievable.

Batch Status Management

Beyond location and quantity, batches need status workflows:

- QC Hold: Awaiting quality clearance

- Released: Available for allocation

- Restricted: Available only for specific channels

- Blocked: Quality issue identified

- Expired: Past sell-by date

A robust inventory management for food companies system enforces these statuses during order allocation. Blocked batches simply don’t appear as available inventory.

Implementation Consideration: Map your current batch numbering conventions before implementation. Changing batch formats post-go-live creates traceability gaps. If your suppliers use inconsistent formats, build normalization rules into the receiving process.

2. Intelligent FEFO Logic with Exception Handling

FEFO sounds straightforward—ship the nearest expiry first. In practice, it’s far more complex.

A food warehouse management system needs intelligent FIFO/FEFO inventory management that handles real-world scenarios:

Channel-Specific Shelf Life Requirements

Different customers have different requirements:

- Modern trade retailers may demand minimum 70% remaining shelf life

- Traditional trade accepts 50% remaining shelf life

- Export orders often require 80%+ remaining shelf life

- Institutional buyers (hotels, restaurants) may accept shorter windows

Your WMS should apply channel-specific allocation rules automatically. An order from a major retail chain shouldn’t pull stock that technically meets FEFO but violates their shelf life policy.

Dynamic Shelf Life Calculation

Static expiry dates don’t tell the whole story. Your FMCG warehouse management system should calculate:

- Remaining shelf life percentage: (Expiry Date – Today) / Total Shelf Life

- Remaining days: Simple countdown

- Customer-specific cutoff: Based on their contracted requirements

This prevents the costly scenario of shipping compliant stock that gets rejected at receiving. Understanding these nuances is critical when managing perishable inventory effectively.

FEFO Override Controls

Sometimes you need to break FEFO rules deliberately:

- Customer specifically requests a particular batch

- Promotional stock designated for specific campaigns

- Export allocation requiring specific production dates

- Quality investigation requiring batch isolation

The system should allow controlled overrides with mandatory reason codes and approval workflows. This maintains audit trails while enabling operational flexibility.

Allocation Optimization

Advanced stock rotation management goes beyond simple first-expired logic:

- Batch consolidation: Prefer allocating from fewer batches to simplify picking

- Location optimization: Factor in pick path efficiency alongside expiry

- Partial pallet preference: Clear partial pallets before opening new ones

- Minimum days to expiry threshold: Automatically flag or block allocations below threshold

Omneelab’s Advantage: The platform’s data-driven insights engine analyzes historical depletion patterns and automatically flags SKUs at risk of expiry before they become a problem . This predictive approach transforms expiry management from reactive firefighting to proactive optimization.

Pro Tip: Configure alert thresholds at multiple levels—30 days, 15 days, 7 days—with escalating notifications. This gives your team time to activate alternate channels (discount sales, donations, or processing into secondary products) before stock expires.

3. Integrated Cold Chain Management

If you’re operating temperature-controlled warehousing, your WMS and cold chain systems need to talk—constantly.

Here’s what meaningful cold chain management integration looks like:

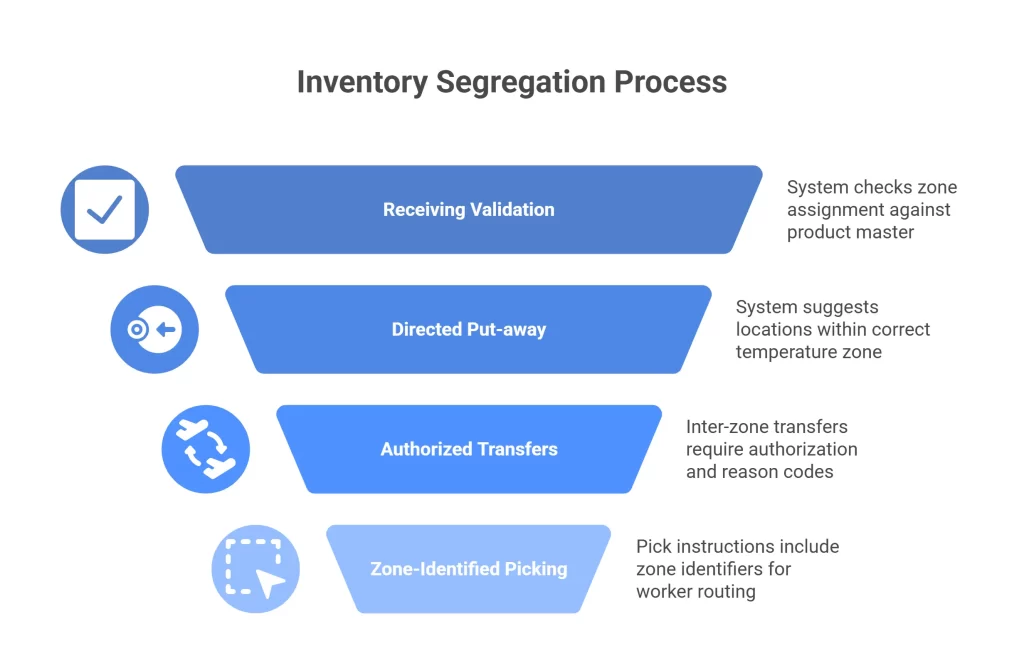

Zone-Based Inventory Segregation

Your WMS should enforce temperature zone constraints at multiple points:

- Receiving: System validates correct zone assignment based on product master

- Put-away: Directed put-away only suggests locations within correct temperature zone

- Transfers: Inter-zone transfers require authorization and reason codes

- Picking: Pick instructions include zone identifiers for worker routing

A cold storage WMS India implementation should make it physically difficult to store products in wrong zones.

Temperature Excursion Management

When sensors detect temperature deviations, the WMS should:

- Automatically place affected inventory on QC hold

- Trigger quality assessment workflow

- Document excursion duration and magnitude

- Link affected batches to the excursion event

- Require QC release before inventory becomes allocable

This cold storage management software capability protects you from shipping compromised products and provides documentation for insurance claims if disposal becomes necessary.

Door Management and Dock Scheduling

Cold chain breaks often happen at dock doors. Your WMS should:

- Schedule inbound and outbound dock appointments

- Minimize door-open duration through timed staging

- Prioritize temperature-sensitive picks during off-peak cooling cycles

- Track dwell time in staging areas

Temperature-Based Lot Differentiation

Here’s an advanced scenario: You receive two pallets of the same SKU. Both have identical batch numbers and expiry dates. But one experienced a temperature excursion during transit.

Your WMS should create differentiated inventory records, allowing you to:

- Ship the unaffected pallet to premium customers

- Route the affected pallet to channels with shorter distribution timelines

- Maintain complete documentation for both

Integration Note: Evaluate IoT platform compatibility early. Leading beverage supply chain software India solutions offer native integrations with major cold chain monitoring platforms. Omneelab WMS stands out here with its extensive integrations across sales channels and courier partners , plus seamless connectivity with ERP systems and IoT platforms through its cloud integration API . Learn more about emerging technologies in warehousing logistics in India.

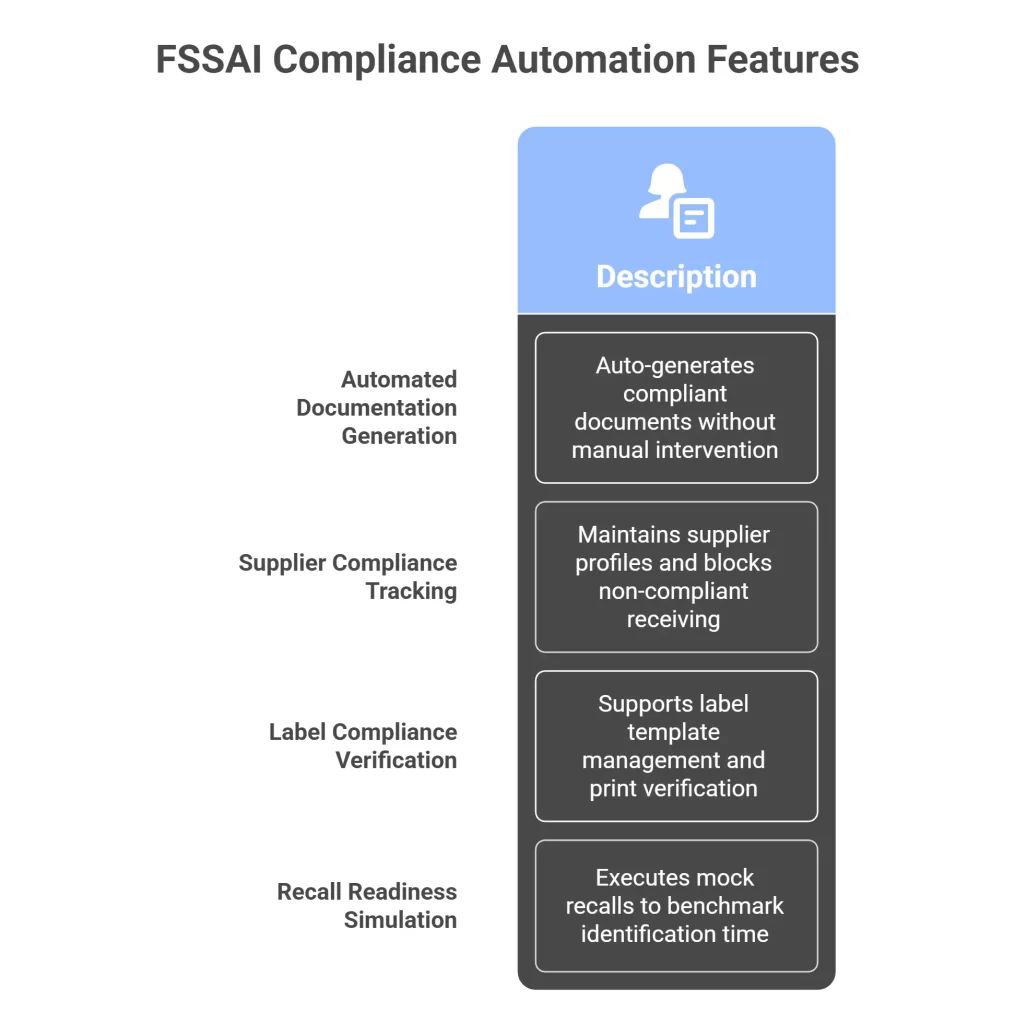

4. FSSAI Compliance Automation

Compliance isn’t a feature—it’s a framework that should permeate your entire food and beverage warehouse software India implementation.

Here’s how mature systems handle FSSAI compliance software requirements:

Automated Documentation Generation

Your WMS should auto-generate compliant documentation without manual intervention:

- Form E (Import): Capturing required fields from receiving transactions

- Batch manufacturing records: Linked to quality inspection results

- Distribution records: Complete chain of custody documentation

- Recall communication templates: Pre-populated with affected batch details

Manual document preparation invites errors and delays. Automation ensures consistency.

Supplier Compliance Tracking

Your WMS should maintain supplier profiles including:

- FSSAI license numbers and validity dates

- Approved product categories per license

- Quality certification status

- Historical quality performance metrics

The system should block receiving from suppliers with expired credentials or unacceptable quality scores.

Label Compliance Verification

For private label or co-packed products, your WMS should support:

- Label template management with version control

- Print verification against master templates

- Mandatory label data capture (MRP, best before, batch)

- Label audit trails

Recall Readiness Simulation

The best way to prepare for recalls is to practice them. Advanced F&B logistics software India systems support:

- Mock recall execution without actual inventory impact

- Time-to-identification benchmarking

- Affected customer list generation

- Downstream notification simulation

Run quarterly mock recalls. Measure your response time. FSSAI mock drills expect identification within 4 hours. Can your system deliver?

Omneelab WMS integrates advanced analytics and real-time reporting to empower businesses with actionable insights . This means audit-ready reports are available at a click—no scrambling when inspectors arrive.

Inspection Audit Mode

When inspectors arrive, your team shouldn’t scramble. Configure an “audit mode” that provides:

- Read-only access for inspectors

- Pre-built report templates for common queries

- Traceability demonstration workflows

- Temperature and quality log exports

Compliance Tip: Document your WMS validation process. If inspectors question system reliability, you need evidence of testing, user training, and ongoing verification procedures. Many of these common inventory management challenges can be mitigated with proper system configuration.

5. Real-Time Visibility with Predictive Capabilities

Basic real-time inventory tracking shows current state. Advanced visibility predicts future states and identifies problems before they materialize.

Here’s what separates adequate from excellent:

Inventory Position Forecasting

Beyond current stock, your WMS should project:

- Available to Promise (ATP): What can you commit against new orders considering current stock minus existing allocations plus expected receipts?

- Expiry Risk Inventory: Which SKUs will have inventory expiring within 30/60/90 days at current depletion rates?

- Stockout Probability: Based on demand patterns and lead times, which items are at risk?

This supply chain visibility transforms your planning from reactive to proactive. Understanding why visibility in supply chain is important helps justify investment in these capabilities.

Multi-Location Inventory Optimization

For businesses with multiple warehouses, multi-location inventory visibility should enable:

- Network-wide ATP: Check availability across all locations simultaneously

- Inter-facility transfer recommendations: Balance stock based on regional demand patterns

- Optimal sourcing suggestions: Which warehouse should fulfill this order based on inventory position, expiry dates, and freight costs?

Exception-Based Management

Your team can’t monitor every transaction. Configure intelligent alerts:

- Inventory accuracy deviations beyond threshold

- Receiving quantity mismatches against PO

- Picks from wrong batches or zones

- Aging inventory crossing threshold

- Velocity changes indicating demand shifts

A good order fulfillment automation framework handles normal operations automatically, freeing your team to focus on exceptions. Omneelab WMS delivers lightning-fast order fulfillment while providing valuable data insights for continuous improvement .

Barcode Infrastructure Considerations

Barcode scanning system design significantly impacts operational efficiency:

| Approach | Pros | Cons |

|---|---|---|

| RF handheld scanners | Durable, dedicated devices | Higher upfront cost, device management overhead |

| Mobile device scanning | Lower cost, familiar interface | Battery life, durability concerns |

| Fixed tunnel scanners | High throughput, hands-free | Limited flexibility, higher installation cost |

| Vision-based systems | Label-free identification possible | Emerging technology, higher complexity |

For most Indian F&B operations, a hybrid approach works best—RF scanners for heavy-duty warehouse operations, mobile devices for supervisory functions and exception handling. Our detailed guide on inventory management with barcode technology covers implementation best practices.

Integration Architecture

Your WMS doesn’t operate in isolation. Plan integrations carefully:

- ERP integration: Master data sync, financial posting, procurement

- TMS integration: Shipment planning, carrier selection, tracking

- E-commerce platforms: Order ingestion, inventory feeds

- Retailer portals: ASN submission, inventory visibility sharing

- IoT platforms: Temperature, humidity, location sensors

Cloud-based WMS India solutions typically offer pre-built connectors that accelerate integration timelines. Omneelab WMS can be integrated with your e-commerce platform, POS system, and ERP system seamlessly , making it ideal for F&B businesses operating across multiple sales channels. Understanding the top WMS integration types and benefits helps you plan your technology roadmap effectively.

Why Omneelab WMS is the Smart Choice for Indian F&B Companies

After evaluating dozens of WMS implementations across the Indian F&B sector, certain platforms consistently outperform others. Omneelab WMS has emerged as a leading choice for food and beverage companies, and here’s why:

Purpose-Built for Indian Operations

Unlike international solutions requiring heavy customization, Omneelab understands Indian regulatory requirements, multi-channel complexity, and local business practices. The platform is designed ground-up for Indian market realities.

Comprehensive Integration Ecosystem

With extensive integrations across sales channels and courier partners , Omneelab eliminates the integration headaches that plague many WMS implementations. Whether you’re selling through modern trade, general trade, e-commerce marketplaces, or D2C channels, Omneelab connects seamlessly.

AI-Powered Intelligence

Omneelab leverages AI-powered warehouse management solutions that go beyond basic automation. The system learns from your operations, identifying optimization opportunities and predicting issues before they impact your business.

Cloud-First Architecture

The Omneelab Warehouse Management Cloud Integration API enables rapid deployment and easy scaling. No heavy infrastructure investments. No lengthy IT projects. You can be operational in weeks, not months.

Proven Track Record

From fashion e-commerce to FMCG distribution, Omneelab has demonstrated success across diverse Indian business scenarios. The platform’s flexibility makes it equally effective for single-warehouse operations and complex multi-location networks.

Vendor Evaluation Framework

When evaluating top WMS vendors in India, structure your assessment around these dimensions:

Functional Fit

Score vendors against your specific requirements. Generic capability matrices don’t reveal F&B-specific depth. Request demonstrations using your actual scenarios:

- Walk through a multi-batch receipt with varying expiry dates

- Show FEFO allocation with channel-specific shelf life rules

- Demonstrate a mock recall

- Display temperature excursion handling

For a comprehensive framework, refer to our guide on choosing the right warehouse management solution.

Implementation Methodology

Ask detailed questions:

- What’s your typical timeline for F&B implementations of similar scope?

- How many Indian F&B customers have you implemented?

- Who leads implementation—your team or partners?

- What’s the resource requirement from our side?

Total Cost Analysis

Look beyond license fees:

| Cost Component | One-Time | Recurring |

|---|---|---|

| Software license/subscription | ✓ | ✓ |

| Implementation services | ✓ | |

| Customization development | ✓ | |

| Integration development | ✓ | |

| Hardware procurement | ✓ | |

| Training | ✓ | ✓ |

| Annual maintenance/support | ✓ | |

| Upgrade costs | ✓ | |

| Additional user licenses | ✓ |

For supply chain management software for F&B, expect total first-year investment of 1.5-2x the quoted software cost once you include implementation and infrastructure. Omneelab’s transparent pricing and rapid deployment model often delivers faster time-to-value compared to legacy alternatives.

Scalability Evidence

Ask for reference customers who have scaled on the platform. Talk to them directly. Questions to ask:

- How did the system handle volume growth?

- What was the upgrade experience like?

- Were there unexpected costs as you scaled?

- Would you choose the same vendor again?

Implementation Pitfalls to Avoid

Based on patterns across Indian F&B implementations:

Underestimating Master Data Complexity

Product master data in F&B is complex—shelf life definitions, storage requirements, unit conversions, regulatory classifications. Budget adequate time for data cleansing and enrichment. Our comprehensive guide to inventory management systems covers master data best practices in detail.

Insufficient Testing with Real Volumes

Systems that work fine with 100 test transactions may struggle with 10,000 daily transactions. Insist on load testing before go-live.

Parallel Running Shortcuts

Running old and new systems in parallel is painful but necessary. Cutting this phase short leads to data gaps and user trust issues.

Training Underinvestment

Warehouse operators may resist new systems. Invest in change management, not just button-clicking training. Help them understand why the new processes matter.

Ignoring Exception Processes

Focus on normal flows during implementation often leaves exception handling undefined. Document and configure processes for returns, damages, holds, and adjustments.

Conclusion

The best WMS for food industry India isn’t the one with the longest feature list. It’s the one that addresses your specific operational challenges while scaling with your growth.

To summarize the five essential capabilities:

- Advanced Batch Tracking: Granular, multi-attribute traceability with nested hierarchies

- Intelligent FEFO Logic: Channel-aware allocation with controlled override capabilities

- Integrated Cold Chain: Seamless temperature monitoring with automated excursion management

- FSSAI Compliance Automation: Documentation generation, supplier tracking, and recall readiness

- Predictive Visibility: Beyond current state to forecasting and exception-based management

The Indian F&B market is professionalizing rapidly. Retailers demand better service levels. Consumers expect freshness and safety. Regulators require complete traceability.

A properly implemented warehouse management system for F&B companies delivers competitive advantage—lower spoilage, better fill rates, faster recalls, and compliant operations.

Your next step: Conduct a gap analysis against these five capabilities. Identify where your current operations fall short. Quantify the cost of those gaps—spoilage, compliance risk, service failures. That business case will drive your WMS investment decision.

Ready to transform your F&B warehouse operations? Omneelab WMS offers the AI-powered intelligence, seamless integrations, and India-specific capabilities your business needs. With real-time inventory oversight, lightning-fast order fulfillment, and extensive marketplace connectivity, Omneelab helps food and beverage companies compete and win in India’s demanding market. Request a demo today and see the difference purpose-built technology makes.

Frequently Asked Questions (FAQs)

Set up a rule hierarchy where customer-requested batches take priority over FEFO when explicitly specified. Implement approval workflows with mandatory reason codes for overrides to maintain audit trails. Track override frequency—excessive overrides signal configuration or process issues needing attention.

Define channel-specific minimum remaining shelf life percentages in your product-channel master data. Configure ATP calculations to automatically exclude inventory that violates channel policies. Set up automated alerts for products nearing channel thresholds so your team can trigger channel reallocation proactively.

Define zones as logical groupings rather than physical areas for flexibility. Map each zone to acceptable temperature ranges with tolerance bands. Configure product masters with preferred and acceptable zone lists, and ensure your WMS enforces zone constraints at every inventory movement point—not just put-away.

Middleware-based integration outperforms direct point-to-point connections—it’s easier to maintain and adapt. Use real-time integration for critical transactions (inventory movements, order status) and batch integration for master data sync. Omneelab’s cloud integration API simplifies this with pre-built connectors for major platforms.

Track key KPIs: inventory accuracy (>99%), order fulfillment accuracy (>99.5%), spoilage rate reduction (20-30% improvement), and picking productivity. Conduct post-implementation reviews at 30, 90, and 180 days. Compare actual versus projected ROI to inform future technology decisions.

Kapil Pathak is a Senior Digital Marketing Executive with over four years of experience specializing in the logistics and supply chain industry. His expertise spans digital strategy, search engine optimization (SEO), search engine marketing (SEM), and multi-channel campaign management. He has a proven track record of developing initiatives that increase brand visibility, generate qualified leads, and drive growth for D2C & B2B technology companies.