The holiday season brings unprecedented challenges for businesses worldwide. Picture this: it’s Black Friday morning, orders are flooding in at triple the normal rate, and your warehouse team is scrambling to keep up. Sound familiar? You’re not alone.

According to the National Retail Federation, holiday retail sales increased by 5.4% in 2023, reaching $964.4 billion, with e-commerce accounting for a significant portion of this growth. Smart inventory management has become the lifeline for businesses navigating the chaotic waters of festive season demand.

In today’s fast-paced retail environment, traditional inventory methods simply can’t handle the explosive growth in holiday rush management. That’s where mobile-first warehouse management systems (WMS) step in as game-changers, transforming how businesses approach festive season inventory challenges.

What is Smart Inventory Management?

Smart inventory management represents a revolutionary approach to warehouse operations that leverages artificial intelligence, real-time data analytics, and mobile technology to optimize every aspect of inventory control. Unlike traditional systems that rely on manual processes and periodic updates, smart systems provide continuous visibility into stock levels, demand patterns, and operational efficiency.

At its core, a smart warehouse system integrates multiple technologies:

- AI-powered logistics for predictive analytics

- Real-time inventory control through IoT sensors

- Mobile warehouse solutions for on-the-go management

- Cloud-based inventory platforms for scalability

The beauty of modern smart inventory management software lies in its ability to anticipate problems before they occur. Instead of reacting to stockouts or overstock situations, businesses can proactively adjust their strategies based on intelligent forecasting and automated alerts.

The Festive Season Challenge: Why Traditional Methods Fall Short

Every year, retailers face the same nightmare scenario during peak seasons. Peak season fulfillment demands can increase by 300-500%, yet many businesses still rely on outdated systems that weren’t designed for such volatility.

Traditional inventory methods struggle with:

- Manual data entry leading to human errors

- Delayed updates causing inventory discrepancies

- Limited visibility across multiple channels

- Inflexible systems that can’t scale quickly

- Poor communication between warehouse teams

Consider a typical scenario: A popular electronics retailer experiences a sudden surge in smartphone orders during Diwali. Their legacy system shows 500 units in stock, but the actual count is only 200. By the time they discover the discrepancy, they’ve oversold by 300 units, leading to disappointed customers and damaged reputation.

This is where mobile WMS platforms shine. They provide real-time accuracy, instant updates, and the flexibility to handle sudden demand spikes without missing a beat.

How Mobile-First WMS Platforms Transform Holiday Operations

Real-Time Visibility and Control

Modern mobile warehouse solutions put the power of complete inventory oversight directly into the hands of warehouse managers and staff. Through intuitive mobile apps, teams can:

- Track inventory movements in real-time

- Update stock levels instantly via barcode scanning

- Monitor order fulfillment progress from anywhere

- Receive automated alerts for low stock or urgent orders

The real-time inventory control capability means that when a customer places an order online, the system immediately reserves that item, preventing overselling and ensuring accurate availability across all sales channels.

AI-Powered Demand Forecasting

Demand forecasting becomes incredibly sophisticated with AI integration. Research by McKinsey & Company shows that companies using AI-powered supply chain management can reduce forecasting errors by 20-50% and decrease inventory holding costs by 20-40%. The system analyzes:

- Historical sales data from previous festive seasons

- Current market trends and consumer behavior

- External factors like weather, events, and promotions

- Social media sentiment and search trends

This intelligent analysis helps businesses prepare for demand surges weeks in advance, ensuring optimal stock levels without tying up excessive capital in inventory.

Seamless Omnichannel Integration

Today’s consumers shop across multiple channels – online, in-store, mobile apps, and social media. Omnichannel inventory management ensures that stock levels are synchronized across all platforms, providing customers with accurate availability information regardless of where they shop.

A mobile WMS platform acts as the central nervous system, coordinating inventory across:

- E-commerce websites

- Physical retail stores

- Mobile applications

- Third-party marketplaces

- Social commerce platforms

For businesses seeking comprehensive solutions, platforms like OmneelabWMS offer integrated mobile-first approaches that seamlessly connect warehouse operations with multi-channel retail environments, ensuring consistent inventory visibility across all touchpoints.

Key Features of Mobile-First WMS for Festive Success

Advanced Barcode Scanning System

Modern barcode scanning systems have evolved far beyond simple product identification. Today’s mobile solutions offer:

- Multi-format scanning (QR codes, barcodes, RFID)

- Batch processing for faster operations

- Voice-guided picking for hands-free operation

- Photo verification to ensure accuracy

Cloud-Based Scalability

Cloud-based inventory platforms provide the flexibility to scale operations up or down based on seasonal demands. During peak periods, businesses can:

- Add temporary users without hardware investments

- Increase processing capacity automatically

- Access data from anywhere with internet connectivity

- Integrate with temporary staff quickly and efficiently

Automated Order Fulfillment

Order fulfillment automation reduces manual errors and speeds up processing times significantly. Key automation features include:

- Intelligent order routing to the nearest fulfillment center

- Automated picking lists optimized for warehouse layout

- Smart packing suggestions to minimize shipping costs

- Automatic carrier selection based on delivery requirements

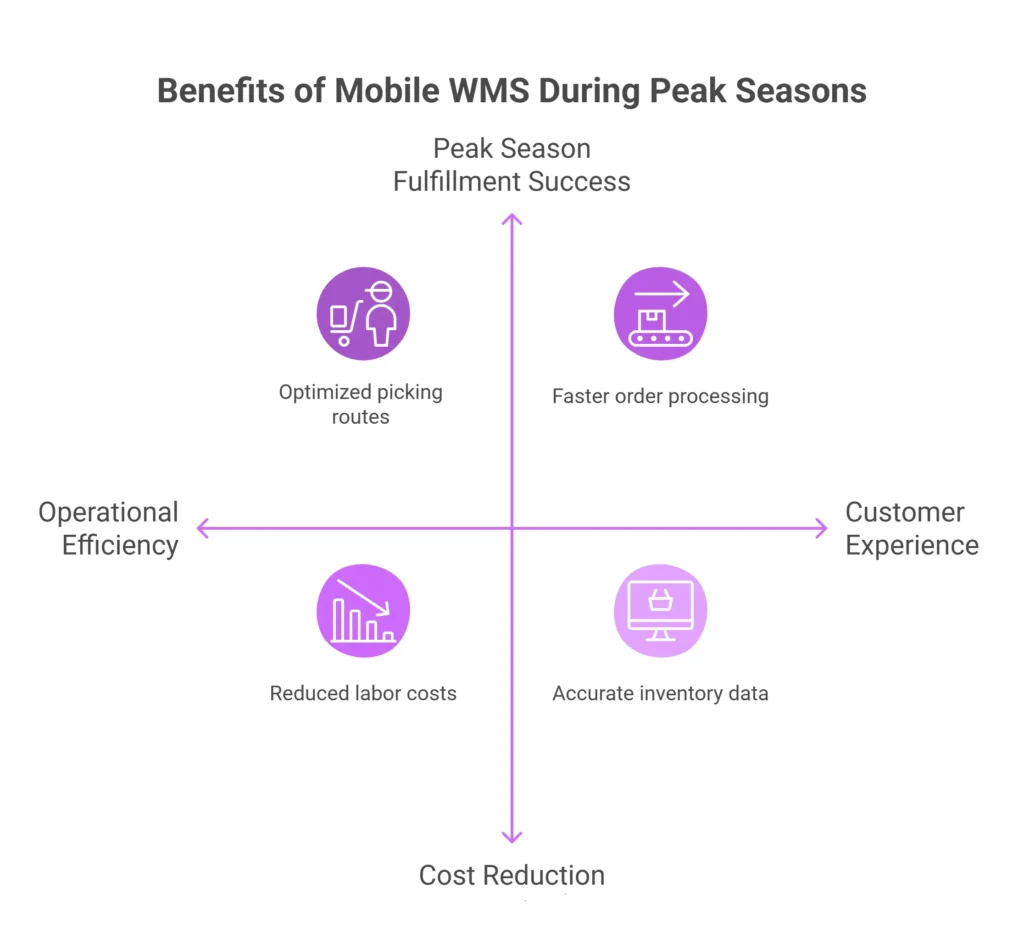

Benefits of Mobile WMS During Peak Seasons

Enhanced Operational Efficiency

Mobile-first systems dramatically improve warehouse productivity through:

- Reduced walking time with optimized picking routes

- Faster data entry through voice commands and scanning

- Improved accuracy with real-time verification

- Better resource allocation based on live demand data

Cost Reduction and ROI

Businesses typically see significant cost savings through:

- Reduced labor costs due to improved efficiency

- Lower inventory carrying costs through better forecasting

- Decreased stockout losses with accurate demand planning

- Minimized returns due to improved order accuracy

Superior Customer Experience

Peak season fulfillment success directly impacts customer satisfaction:

- Faster order processing leads to quicker deliveries

- Accurate inventory data prevents disappointing stockouts

- Real-time tracking keeps customers informed

- Consistent quality maintains brand reputation

How to Prepare Your Warehouse for Holiday Rush

Step 1: Assess Current Capabilities

Before implementing new systems, evaluate your existing warehouse management system performance:

- Analyze last year’s peak season data

- Identify bottlenecks and pain points

- Calculate current system capacity limits

- Review staff training and readiness

Step 2: Choose the Right Mobile WMS Platform

When selecting inventory tracking software, consider:

- Scalability to handle demand spikes

- Integration capabilities with existing systems

- User-friendly interface for quick staff adoption

- Robust reporting for data-driven decisions

- 24/7 support during critical periods

Step 3: Staff Training and Preparation

Successful implementation requires comprehensive training:

- Mobile app navigation and basic functions

- Emergency procedures for system issues

- Quality control processes for accuracy

- Communication protocols for coordination

Step 4: Test and Optimize

Before the rush begins:

- Run simulation tests with expected volumes

- Optimize warehouse layout for mobile workflows

- Fine-tune automation rules based on business needs

- Establish backup procedures for contingencies

AI and Machine Learning in Warehouse Management

Predictive Analytics for Inventory Optimization

AI-powered logistics systems excel at pattern recognition and prediction:

- Seasonal trend analysis identifies recurring patterns

- Customer behavior modeling predicts purchase likelihood

- Supply chain optimization minimizes lead times

- Dynamic pricing suggestions maximize profitability

Intelligent Automation Features

Modern systems offer sophisticated automation:

- Smart replenishment triggers based on velocity and lead times

- Automated quality checks using computer vision

- Predictive maintenance for warehouse equipment

- Dynamic slotting optimization for faster picking

Integration with Existing Systems

ERP and Accounting Software

Seamless integration with enterprise systems ensures:

- Synchronized financial data for accurate reporting

- Automated invoice generation upon shipment

- Real-time cost tracking for profitability analysis

- Compliance reporting for regulatory requirements

E-commerce Platforms

E-commerce Platforms Distribution center technology must integrate smoothly with:

- Shopping cart systems for real-time inventory updates

- Payment processors for order confirmation

- Shipping carriers for automated label generation

- Customer service tools for order inquiries

Measuring Success: KPIs for Festive Season Performance

Operational Metrics

Track these key performance indicators:

- Order fulfillment speed (time from order to ship)

- Inventory accuracy percentage

- Pick accuracy rates

- Warehouse productivity (orders per hour)

- System uptime during peak periods

Financial Metrics

Monitor business impact through:

- Revenue per square foot of warehouse space

- Inventory turnover rates during peak season

- Cost per order fulfillment

- Return on investment for WMS implementation

Customer Satisfaction Metrics

Measure customer experience via:

- On-time delivery percentages

- Order accuracy rates

- Customer complaint volumes

- Net Promoter Score improvements

Future Trends in Mobile Warehouse Management

Emerging Technologies

The future of smart warehouse automation solutions includes:

- Augmented reality for guided picking and training

- Robotics integration for automated material handling

- Blockchain technology for supply chain transparency

- 5G connectivity for ultra-fast data transmission

Sustainability Focus

Environmental considerations are driving innovation:

- Energy-efficient operations through smart scheduling

- Reduced packaging waste via optimization algorithms

- Carbon footprint tracking for sustainability reporting

- Circular economy integration for returns processing

According to a Zebra Technologies study, 87% of warehouse decision-makers plan to increase their investment in mobile and wearable technology by 2025, recognizing the critical role these solutions play in maintaining competitive advantage during peak seasons.

The Complete End-to-End Solution: From Warehouse to Doorstep

While warehouse efficiency is crucial, the customer experience extends beyond the fulfillment center. The final mile of delivery often makes or breaks customer satisfaction during festive seasons. This is where last mile SaaS solutions become essential, providing real-time delivery tracking, dynamic route optimization, and seamless communication between delivery partners and customers.

Modern businesses require integrated solutions that connect warehouse operations with final delivery execution, ensuring that the efficiency gained in inventory management translates directly into superior customer experiences at the doorstep.

Conclusion: Embracing the Mobile-First Future

The festive season will always bring challenges, but smart inventory management through mobile-first WMS platforms provides the tools to not just survive but thrive during peak periods. By embracing real-time inventory control, AI-powered logistics, and mobile warehouse solutions, businesses can transform their operations from reactive to proactive.

The question isn’t whether you can afford to implement a modern mobile WMS platform – it’s whether you can afford not to. As consumer expectations continue rising and competition intensifies, the businesses that invest in smart technology today will be the ones celebrating success tomorrow.

Ready to revolutionize your festive season inventory management? Start by evaluating your current systems, identifying improvement opportunities, and exploring mobile-first WMS solutions that align with your business goals. The holiday rush doesn’t have to be a nightmare – with the right tools and preparation, it can become your competitive advantage.

Frequently Asked Questions

A warehouse management system (WMS) is a comprehensive platform managing all warehouse operations including receiving, picking, packing, and shipping. Inventory management software focuses specifically on tracking stock levels and locations. While inventory management is a WMS component, a full WMS provides broader operational control including labor management and workflow automation.

AI-powered logistics systems analyze historical data and current trends to predict demand patterns accurately. During festive seasons, AI automatically adjusts reorder points, optimizes picking routes, predicts staffing needs, and identifies potential bottlenecks before they occur. This proactive approach ensures smooth operations during unprecedented demand spikes.

Essential features include real-time inventory tracking, barcode scanning system integration, offline capability, automated order fulfillment workflows, customizable dashboards, ERP integration, and robust reporting. The platform should offer scalability for increased transaction volumes, voice-guided picking, and instant alert systems for urgent orders.

Preparation involves implementing smart warehouse systems before peak season, training staff on new technologies, optimizing warehouse layout for mobile workflows, and conducting stress tests with expected volumes. Start planning 3-4 months ahead, cross-train employees, create contingency plans, and establish partnerships with reliable carriers.

Cloud-based inventory platforms offer instant scalability for increased transaction volumes, remote access for distributed teams, automatic updates without downtime, reduced IT costs, and enhanced data security. During festive seasons, you can add temporary users without hardware purchases and ensure system operation during peak traffic.

Kapil Pathak is a Senior Digital Marketing Executive with over four years of experience specializing in the logistics and supply chain industry. His expertise spans digital strategy, search engine optimization (SEO), search engine marketing (SEM), and multi-channel campaign management. He has a proven track record of developing initiatives that increase brand visibility, generate qualified leads, and drive growth for D2C & B2B technology companies.