In today’s fast-paced retail environment, where customer demand changes in the blink of an eye, traditional replenishment strategies often fall short. Retailers need to adopt demand-driven replenishment practices to ensure the right products are available at the right time, minimizing stockouts and overstocking. This article explores the best demand-driven replenishment practices for retailers, offering actionable insights to optimize inventory management, boost customer satisfaction, and improve supply chain efficiency.

Introduction

Picture this: A customer walks into your store looking for a popular item, only to find it out of stock. Frustrated, they shop elsewhere, and you lose not only a sale but potentially a loyal customer. On the flip side, overstocking leads to tied-up capital and higher storage costs. Both scenarios highlight the importance of balancing supply with demand.

Demand-driven replenishment focuses on real-time data and predictive analytics to align inventory with actual customer needs. This proactive approach is transforming retail supply chains, enabling businesses to respond dynamically to fluctuations in demand. In this article, we’ll dive into the most effective strategies for retailers to implement demand-driven inventory management and future-proof their operations.

What is Demand-driven Replenishment?

Demand-driven replenishment is a strategy where retailers use real-time demand data, advanced analytics, and forecasting tools to optimize inventory levels. Unlike traditional replenishment methods that rely on historical trends, this approach ensures that stock is replenished based on current customer demand trends and anticipated future needs.

Key benefits of demand-driven inventory management include:

- Improved inventory accuracy: Reducing overstocking and stockouts.

- Cost savings: Minimizing storage costs and wastage.

- Enhanced customer satisfaction: Ensuring products are always available when customers need them.

- Agility in supply chain management: Adapting quickly to changes in demand patterns.

Best Demand-driven Replenishment Practices for Retailers

Let’s explore the most effective practices that retailers can adopt for demand-driven supply chain strategies and optimized replenishment.

1. Invest in Real-time Demand Tracking Tools

To implement a demand-driven approach, retailers must invest in real-time demand tracking systems. These tools capture sales data, customer preferences, and market trends in real-time, enabling accurate inventory decisions.For example:

- A just-in-time inventory management system ensures that stock is replenished only when needed, reducing excess inventory.

- Integration with point-of-sale (POS) systems allows retailers to monitor sales patterns and adjust replenishment schedules dynamically.

Pro Tip: Use AI-driven inventory solutions to analyze demand trends and automate replenishment processes.

2. Leverage Predictive Analytics for Forecasting

Accurate demand forecasting for retailers is the cornerstone of demand-driven replenishment. Predictive analytics uses historical data, market trends, and external factors (like seasonality or promotions) to predict future demand.

How to implement predictive analytics in retail:

- Use retail inventory planning tools to analyze past sales trends and seasonal variations.

- Incorporate external factors like weather forecasts or economic conditions to refine predictions.

- Regularly update forecasts with real-time data for better accuracy.

Retailers using predictive analytics can anticipate customer needs and maintain optimal inventory levels, ensuring they’re always one step ahead.

3. Automate Replenishment Processes

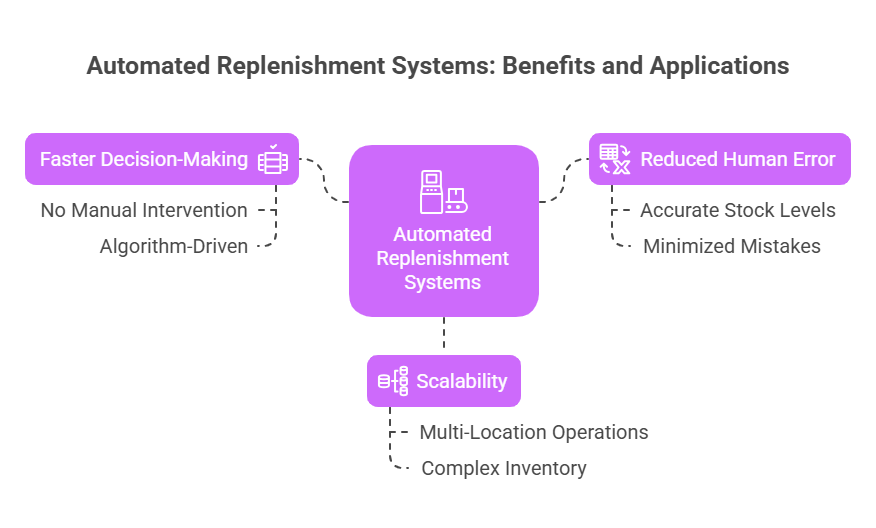

Automation is a game-changer for efficient stock management. Automated replenishment systems use algorithms to determine when and how much stock to reorder, removing the guesswork from inventory decisions.

Benefits of automated replenishment:

- Faster decision-making: No need for manual intervention.

- Reduced human error: Ensures stock levels are always accurate.

- Scalability: Handles complex, multi-location operations seamlessly.

Retailers like Amazon rely heavily on automation to manage their vast inventory network, ensuring high supply chain efficiency.

4. Monitor Stock Turnover Rates

Stock turnover rates—how quickly you sell and replace inventory—are a critical metric for demand-driven replenishment. High turnover rates indicate strong demand, while low rates suggest overstocking or slow-moving products.

Tips for optimizing stock turnover:

- Identify fast-moving and slow-moving SKUs (Stock Keeping Units) using SKU-level inventory management.

- Prioritize replenishment for high-demand items.

- Use markdown strategies to clear slow-moving inventory and free up space.

By consistently monitoring turnover rates, retailers can refine their replenishment strategies and maximize profitability.

5. Implement Seasonal and Event-based Forecasting

Seasonal demand forecasting is essential for retailers who experience fluctuations in demand due to holidays, weather changes, or special events. For instance, demand for winter clothing spikes during the colder months, while school supplies see a surge before the academic year begins.

Steps to implement seasonal forecasting:

- Analyze historical sales data for seasonal patterns.

- Plan replenishment schedules around upcoming events or promotions.

- Adjust forecasts dynamically as new data becomes available.

This ensures that retailers are well-prepared for demand surges, avoiding stockouts during peak periods.

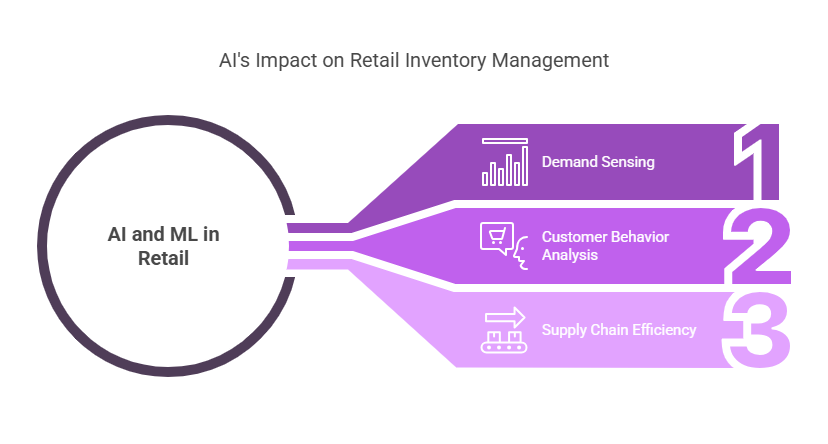

6. Adopt AI and Machine Learning for Data-driven Decisions

Artificial intelligence (AI) and machine learning (ML) are revolutionizing demand-driven inventory management. These technologies analyze vast amounts of data to uncover patterns and provide actionable insights.

Applications of AI in retail supply chain management:

- Demand sensing: AI identifies real-time demand signals to adjust replenishment schedules.

- Customer behavior analysis: Predicts buying patterns to optimize inventory.

- Supply chain efficiency: AI-driven tools streamline logistics and reduce lead times.

By leveraging AI and ML, retailers can make data-driven decisions that enhance operational efficiency and customer satisfaction.

7. Collaborate with Suppliers for Better Alignment

Strong collaboration with suppliers is key to effective retail supply chain management. By sharing demand forecasts and inventory data with suppliers, retailers can ensure timely replenishments and avoid delays.

Tips for supplier collaboration:

- Use digital platforms to share real-time data with suppliers.

- Establish clear communication channels for order updates.

- Negotiate flexible contracts to accommodate demand fluctuations.

This partnership creates a seamless supply chain that aligns with customer needs.

Omneelab: A Comprehensive Solution for Demand-driven Replenishment

Retailers looking for a robust, all-in-one solution to streamline their demand-driven inventory management should consider Omneelab. This advanced platform offers cutting-edge tools to optimize inventory, improve supply chain efficiency, and enhance decision-making.

Key Features of Omneelab:

- Real-time Demand Tracking: Omneelab integrates seamlessly with POS systems and other data sources to provide real-time insights into customer demand.

- AI-driven Forecasting: The platform uses predictive analytics and machine learning to anticipate demand trends, ensuring accurate replenishment decisions.

- Automated Replenishment: Omneelab automates the replenishment process, reducing manual intervention and minimizing errors.

- SKU-level Management: Retailers can track and manage inventory at the SKU level, ensuring optimal stock levels for every product.

- Scalability: Whether you’re a small retailer or a large enterprise, Omneelab’s flexible solutions can scale to meet your needs.

By adopting Omneelab, retailers can simplify their inventory management processes, reduce costs, and improve customer satisfaction. It’s a powerful tool for businesses aiming to stay competitive in today’s dynamic retail landscape.

Benefits of Demand-driven Replenishment

By adopting these practices, retailers can unlock a host of benefits:

- Reduced Costs: Minimize excess inventory and storage expenses.

- Improved Cash Flow: Free up capital tied in unsold stock.

- Enhanced Customer Satisfaction: Ensure product availability at all times.

- Operational Efficiency: Streamline supply chain processes and reduce lead times.

- Competitive Advantage: Stay ahead of competitors by responding quickly to demand changes.

Conclusion

In today’s competitive retail landscape, demand-driven replenishment practices are no longer optional—they’re essential. By leveraging real-time data, predictive analytics, and AI-driven tools like Omneelab, retailers can optimize inventory management, reduce costs, and deliver exceptional customer experiences.Start implementing these strategies today to transform your retail operations. Remember, the key to success lies in staying agile, proactive, and customer-focused.

Ready to take your retail operations to the next level? Explore advanced AI tools and inventory planning solutions like Omneelab to streamline your supply chain and embrace the future of demand-driven replenishment. Don’t wait—start optimizing your inventory today!

FAQs

Demand-driven replenishment offers several key benefits, including:

– Reduced stockouts: Ensuring products are available when customers need them.

– Minimized overstocking: Reducing excess inventory and associated storage costs.

– Improved cash flow: Freeing up capital tied in unsold stock.

– Enhanced supply chain efficiency: Adapting quickly to demand fluctuations.

– Better customer satisfaction: Meeting customer expectations with on-time availability.

Omneelab is a cutting-edge solution that simplifies demand-driven replenishment by:

– Providing real-time demand tracking for accurate inventory management.

– Using predictive analytics to forecast future demand based on sales trends and external factors.

– Automating replenishment processes to reduce manual intervention and errors.

– Offering SKU-level inventory management to optimize stock for every product category.

Demand-Driven Material Requirements Planning (DDMRP) is an advanced methodology that focuses on aligning inventory with real-time demand. It helps retailers:

– Respond dynamically to fluctuating demand.

– Use buffer zones to protect against variability in supply and demand.

Prioritize inventory replenishment based on actual consumption rather than forecasts.

DDMRP is especially valuable in today’s fast-changing retail environment, as it ensures inventory optimization and reduces excess stock.

A demand forecasting dashboard is a visual tool that consolidates real-time sales data, historical trends, and external factors (like seasonality) to provide actionable insights. It helps retailers:

– Monitor real-time demand trends.

– Predict future inventory requirements using predictive analytics.

– Track SKU performance and regional demand patterns.

– Make data-driven decisions to optimize replenishment and inventory allocation.

People also read:

- Guide to Managing Perishable Inventory

- WMS for BigCommerce

- Inventory Management with Barcode Technology

- Common Inventory Management Challenges

- Comprehensive Guide to Inventory Management Systems

- Manual and Automated Inventory Management

- Top 10 Tips for Warehouse Management Software

- Small Business Barcoding

Kapil Pathak is a Senior Digital Marketing Executive with over four years of experience specializing in the logistics and supply chain industry. His expertise spans digital strategy, search engine optimization (SEO), search engine marketing (SEM), and multi-channel campaign management. He has a proven track record of developing initiatives that increase brand visibility, generate qualified leads, and drive growth for D2C & B2B technology companies.