Managing perishable inventory can be a daunting task for businesses dealing with food, pharmaceuticals, or any items that come with a limited shelf life. Without proper strategies, companies risk inventory spoilage, financial losses, and even reputational harm. But fear not—this guide will walk you through perishable inventory management, offering actionable strategies, tracking tips, and even a free inventory management template to streamline your processes.

Whether you’re a small business owner or an inventory manager of a large supply chain, this guide will equip you with the tools and knowledge you need to reduce waste, optimize stock, and operate efficiently.

Why Managing Perishable Inventory Is Critical

Understanding the Challenges

Perishable inventory presents unique challenges compared to non-perishable goods. Items such as fresh produce, dairy products, seafood, and vaccines have a specific shelf life, meaning they can spoil or expire if not managed properly. Poor inventory management can lead to issues like:

- Increased inventory shrinkage (loss due to spoilage or theft).

- Reduced profitability from wasted stock.

- Customer dissatisfaction due to stockouts or receiving expired products.

- Non-compliance with food safety regulations or other industry standards.

The Cost of Neglecting Perishable Goods

Did you know that global food waste amounts to 1.3 billion tons annually? Much of this waste stems from poor inventory management practices. For businesses, this translates to lost revenue and higher operating costs. That’s why adopting effective perishable inventory strategies is crucial for sustainable growth.

Proven Strategies for Managing Perishable Inventory

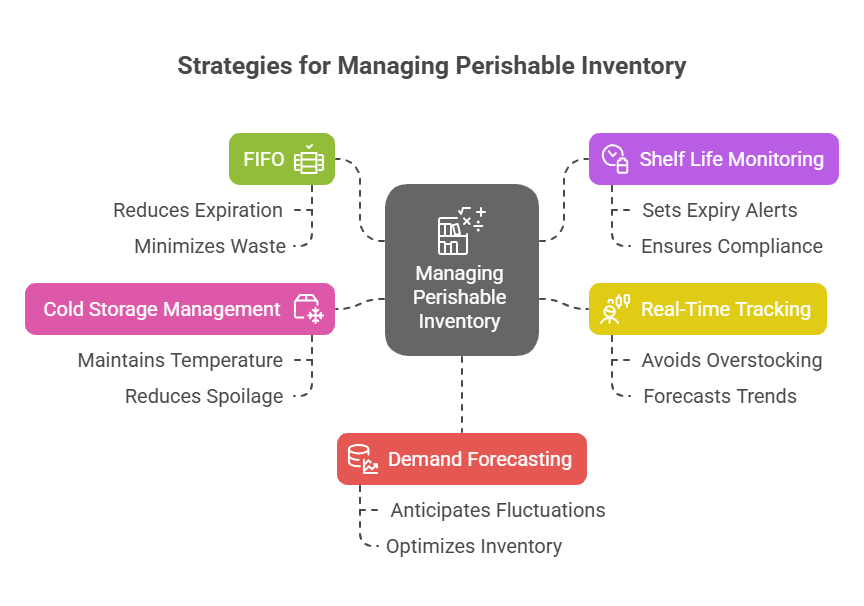

To maintain profitability and ensure customer satisfaction, businesses must implement robust strategies tailored to the unique needs of perishable goods. Below are five key strategies you can adopt today.

1. Implement FIFO (First In, First Out)

The FIFO method, or “First In, First Out,” is a golden rule in perishable inventory management. This system ensures that older stock is sold or used before newer stock. For example, in a grocery store, older milk cartons are placed at the front of the shelf, while newer ones are stored at the back.

Why It Works:

- Reduces the likelihood of products expiring before sale.

- Minimizes waste and inventory shrinkage.

- Simplifies stock rotation for employees.

2. Monitor Shelf Life and Expiry Dates

Accurate expiry date tracking is non-negotiable when managing perishable goods. Use inventory tracking software that enables you to:

- Set alerts for upcoming expiration dates.

- Categorize products based on shelf life.

- Generate detailed reports on inventory turnover.

This approach not only prevents spoilage but also ensures compliance with food safety regulations.

3. Invest in Real-Time Inventory Tracking

Gone are the days of manual stock counts. Today’s businesses rely on real-time inventory tracking systems to monitor stock levels, expiration dates, and storage conditions. Software solutions provide insights into:

- Inventory replenishment strategies to avoid overstocking.

- Seasonal trends in demand forecasting.

- Automated alerts for low-stock or expired items.

4. Optimize Cold Storage Management

If your perishable inventory requires refrigeration or freezing, cold storage inventory management is critical. Ensure that:

- Storage units are maintained at the correct temperature.

- Regular inspections are conducted to identify malfunctions.

- Items are organized to maximize airflow and efficiency.

Proper cold storage not only preserves the quality of goods but also reduces the risk of inventory shrinkage due to spoilage.

5. Leverage Demand Forecasting

Understanding customer demand is key to optimizing your inventory. Tools that analyze historical sales data and market trends can help you:

- Anticipate seasonal fluctuations.

- Avoid overstocking or understocking.

- Improve overall inventory optimization.

For example, a bakery might increase its stock of holiday-themed treats during December while scaling back on other products.

Tracking Your Inventory: Tools and Best Practices

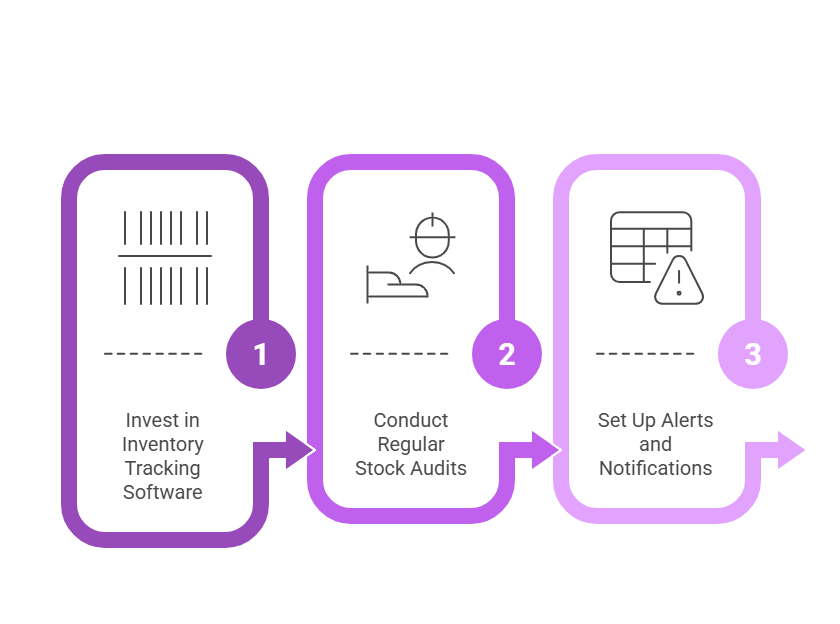

Tracking perishable inventory requires a combination of technology and best practices. Here’s how you can stay on top of your stock:

1. Use Inventory Tracking Software

Invest in an inventory tracking system that integrates with your point-of-sale (POS) system. Look for features such as:

- Barcode scanning for quick and accurate data entry.

- Real-time stock updates.

- Customizable dashboards for tracking key performance indicators (KPIs).

Some popular tools include Omneelab WMS, Zoho Inventory, and UniCommerce.

2. Conduct Regular Stock Audits

Even with automation, regular stock audits are necessary to verify accuracy. Use the following techniques:

- Cycle counting: Focus on auditing small portions of inventory daily or weekly.

- Spot checks: Verify the condition of high-value or fast-moving items.

- Full audits: Conduct a comprehensive inventory check quarterly or annually.

3. Set Up Alerts and Notifications

Automated alerts can save you time and prevent costly mistakes. For example:

- Set up notifications for products nearing their expiration dates.

- Receive low-stock alerts to reorder items before they run out.

- Get temperature alerts for cold storage units.

Free Perishable Inventory Management Template

To get you started, here’s a basic template you can use to track your perishable inventory. This template is designed for simplicity and can be customized to meet your needs:

The Role of AI in Perishable Inventory Management

As technology evolves, AI-powered tools are transforming how businesses manage their perishable inventory. By leveraging AI, you can:

- Predict demand more accurately, even during seasonal fluctuations.

- Automate inventory replenishment based on real-time sales data.

- Optimize storage conditions with advanced monitoring systems.

For example, an AI tool might analyze customer purchasing patterns and suggest stocking more ice cream during a heatwave or reducing inventory of seasonal items after peak demand.

Conclusion: Take Control of Your Perishable Inventory

Managing perishable inventory doesn’t have to be complicated. By implementing strategies like FIFO, real-time tracking, and demand forecasting, you can reduce waste, improve efficiency, and boost your bottom line. Don’t forget to download our free inventory management template to get started on the right foot!

Ready to take your inventory management to the next level? Explore AI-powered tools that can streamline your operations, save time, and maximize profits. The future of inventory management is here—embrace it today!

FAQs

The FIFO (First In, First Out) method is an inventory management strategy that ensures the oldest stock is sold or used first. This is particularly important for perishable items, as it helps prevent spoilage by ensuring that products with the shortest shelf life are prioritized for sale.

To reduce food waste, implement effective inventory management techniques such as accurate expiry date tracking, using the FIFO method, and utilizing inventory tracking software. Additionally, conducting regular audits and demand forecasting can help you better align your stock levels with customer needs, minimizing excess inventory.

Demand forecasting is the process of predicting future customer demand based on historical sales data and market trends. It is crucial for managing perishable inventory because it helps businesses optimize stock levels, avoid overstocking or understocking, and reduce waste due to spoilage.

Automated inventory systems streamline the management of perishable goods by providing real-time tracking, alerts for low stock or approaching expiration dates, and detailed reporting capabilities. This technology reduces manual errors, enhances efficiency, and allows businesses to make informed decisions about inventory replenishment strategies.

Best practices for cold storage inventory management include regularly monitoring and maintaining the correct temperature, organizing items for optimal airflow, implementing real-time tracking to monitor conditions, and conducting routine inspections. These practices help ensure the quality of perishable goods and reduce the risk of spoilage.

People also read:

- Inventory Management with Barcode Technology

- Common Inventory Management Challenges

- Comprehensive Guide to Inventory Management Systems

- Manual and Automated Inventory Management

- Top 10 Tips for Warehouse Management Software

- Small Business Barcoding

Kapil Pathak is a Senior Digital Marketing Executive with over four years of experience specializing in the logistics and supply chain industry. His expertise spans digital strategy, search engine optimization (SEO), search engine marketing (SEM), and multi-channel campaign management. He has a proven track record of developing initiatives that increase brand visibility, generate qualified leads, and drive growth for D2C & B2B technology companies.