The Indian logistics sector is booming, with third-party logistics (3PL) companies handling increasingly complex operations across multiple locations. Yet, many 3PL WMS India implementations fail to deliver expected results, costing businesses millions in lost efficiency and customer satisfaction.

If you’re a 3PL operator in India struggling with warehouse management challenges, you’re not alone. From Mumbai’s bustling distribution centers to Bangalore’s tech-driven fulfillment hubs, logistics companies are making costly mistakes when selecting and implementing warehouse management systems.

This comprehensive guide reveals the most common WMS implementation India pitfalls and provides actionable strategies to ensure your 3PL warehouse management system India drives real business value.

According to a recent industry report, 78% of Indian 3PL companies experienced significant operational disruptions during their first WMS implementation, with poor vendor selection being the leading cause of failure.

Understanding the Indian 3PL WMS Landscape

The warehouse management system India market has evolved dramatically over the past decade. With the rise of e-commerce, GST implementation, and increasing customer expectations, Indian 3PLs face unique challenges. Modern WMS for Shopify ecommerce fulfillment India operations require specialized features that generic solutions often can’t address.

Current market dynamics include:

- Rapid growth in e-commerce fulfillment requirements

- Complex regulatory compliance needs (GST, FSSAI, customs)

- Multi-location warehouse operations across diverse geographies

- Integration challenges with existing ERP and logistics systems

- Skilled workforce shortages in warehouse technology

Understanding these dynamics is crucial before diving into the common mistakes that plague 3PL software India implementations.

Mistake #1: Ignoring India-Specific Compliance Requirements

One of the biggest errors Indian 3PLs make is selecting warehouse management system India solutions without considering local regulatory requirements. This oversight can lead to significant operational disruptions and compliance issues.

GST Compliance Challenges

The Goods and Services Tax (GST) system requires specific documentation and reporting capabilities that many international WMS platforms struggle to support natively. GST compliant WMS India solutions must handle:

- Automatic GST calculation based on product categories

- E-way bill generation and tracking

- GSTR-1 and GSTR-3B report generation

- State-wise tax compliance management

- Reverse charge mechanism handling

How to avoid this mistake:

- Prioritize GST integration WMS India capabilities during vendor evaluation

- Request detailed compliance demonstrations before finalizing your choice

- Ensure the system supports automated tax calculations for different product categories

- Verify integration capabilities with government portals like GST Network (GSTN)

A survey by the Indian Logistics Association revealed that 65% of 3PL operators faced compliance issues within six months of WMS implementation due to inadequate GST integration capabilities.

Industry-Specific Compliance Needs

Different industries have unique compliance requirements that your 3PL warehouse management system India must accommodate:

Pharmaceutical sector: Drug license compliance, batch tracking, temperature monitoring, and FSSAI requirements for pharmaceutical warehouse management India

Food and beverage: Cold chain management, expiry date tracking, and food safety compliance for cold chain WMS India operations

Automotive: Part traceability, recall management, and quality control documentation

Mistake #2: Poor WMS Vendor Selection Process

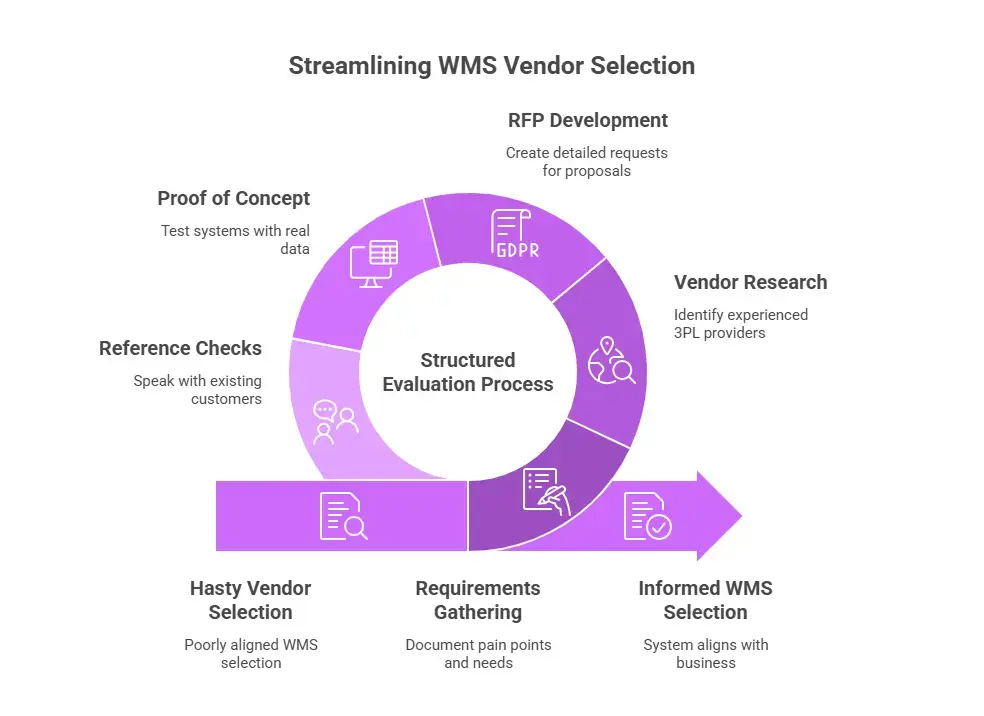

Many Indian 3PLs rush into WMS vendor selection India without following a structured evaluation process. This hasty approach often results in choosing systems that don’t align with business requirements or growth plans.

Common Selection Pitfalls

Focusing solely on cost: While budget constraints are real, choosing the cheapest option often leads to higher long-term costs due to customization needs and operational inefficiencies.

Ignoring scalability: Many Indian 3PL WMS solutions work well for current operations but fail to scale as businesses grow across multiple locations.

Overlooking integration capabilities: Poor integration with existing systems like ERP, TMS, and e-commerce platforms can create operational silos.

Best Practices for WMS Selection

Develop comprehensive WMS selection criteria India:

- Functional requirements mapping

- Technical compatibility assessment

- Vendor stability and local support evaluation

- Total cost of ownership analysis

- Implementation timeline considerations

Create a structured evaluation process by following proven methodologies. Our comprehensive guide on choosing the right warehouse management solution provides detailed selection frameworks for Indian businesses.

- Requirements gathering: Document current pain points and future needs

- Vendor research: Identify logistics software India providers with proven 3PL experience

- RFP development: Create detailed requests for proposals

- Proof of concept: Test systems with real data and scenarios

- Reference checks: Speak with existing customers in similar industries

Mistake #3: Inadequate Change Management and Training

Even the best WMS implementation India can fail without proper change management. Many 3PLs underestimate the human element of technology adoption, leading to user resistance and suboptimal system utilization.

Training Challenges in Indian Context

Language barriers: While English proficiency is growing, many warehouse workers are more comfortable with regional languages. वेयरहाउस मैनेजमेंट सिस्टम training materials in Hindi and other local languages can significantly improve adoption rates.

Varying skill levels: Indian warehouses often have workers with diverse educational backgrounds and technology comfort levels, requiring differentiated training approaches.

High attrition rates: The logistics sector faces significant workforce turnover, making continuous training programs essential.

Effective Change Management Strategies

Develop multilingual training programs:

- Create training materials in local languages

- Use visual aids and hands-on demonstrations

- Implement buddy systems pairing tech-savvy workers with newcomers

Establish clear communication channels:

- Regular feedback sessions with warehouse staff

- Clear escalation procedures for system issues

- Recognition programs for successful adoption

Plan for continuous learning:

- Regular refresher training sessions

- Advanced feature training as users become comfortable

- Cross-training to reduce dependency on key personnel

Research shows that 3PL companies investing in multilingual training programs see 40% higher user adoption rates compared to those using English-only training materials, particularly in tier-2 and tier-3 cities.

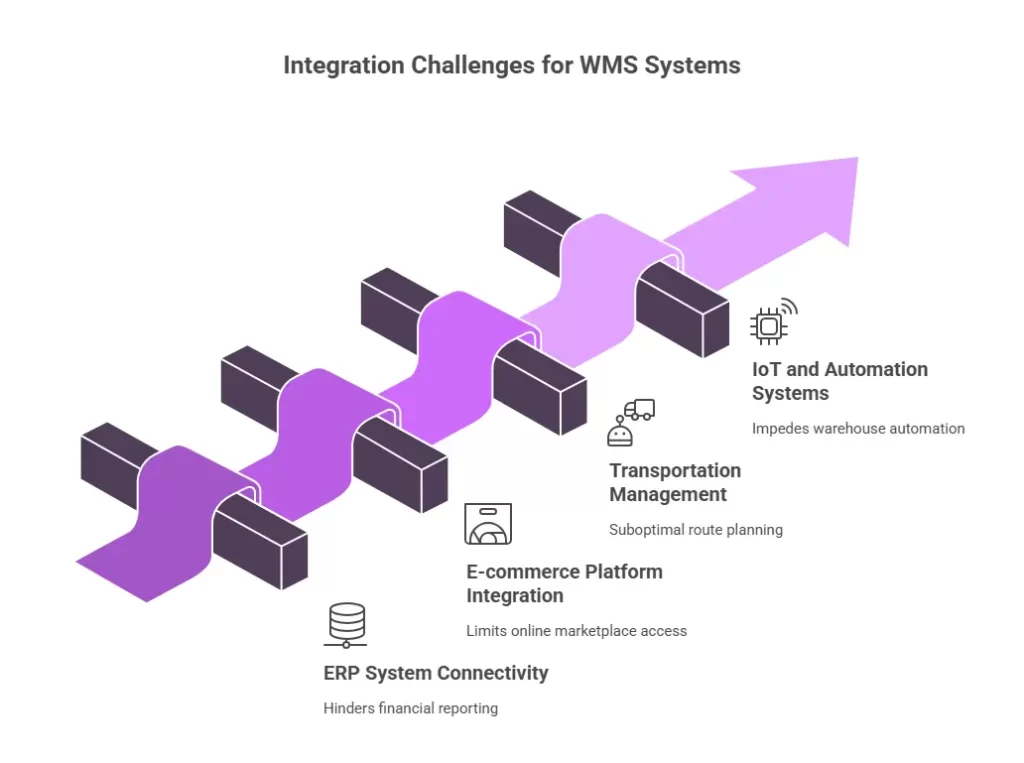

Mistake #4: Underestimating Integration Complexities

3PL system integration India challenges are often more complex than anticipated. Many companies focus on core WMS functionality while overlooking integration requirements with existing systems and emerging technologies.

Common Integration Challenges

ERP system connectivity: Ensuring seamless data flow between WMS and existing ERP systems for financial reporting and inventory management.

E-commerce platform integration: With the growth of ecommerce fulfillment India, WMS must integrate with multiple online marketplaces and shopping platforms. Learn more about WMS integration types and benefits for comprehensive connectivity solutions.

Transportation management: Connecting WMS with TMS for optimal route planning and carrier management.

IoT and automation systems: Integrating with warehouse automation India solutions like conveyor systems, sorting machines, and robotic picking systems.

Integration Best Practices

Conduct thorough system mapping:

- Document all existing systems and data flows

- Identify critical integration points

- Plan for data migration and synchronization

Choose systems with robust APIs:

- Prioritize cloud WMS solutions India with modern integration capabilities

- Ensure real-time data synchronization capabilities

- Plan for future integration needs

Implement phased integration approach:

- Start with critical integrations

- Test thoroughly before moving to production

- Plan for rollback procedures if issues arise

Industry data indicates that integration challenges account for 45% of WMS project delays in India, with ERP connectivity and e-commerce platform integration being the most problematic areas.

Mistake #5: Ignoring Mobile and Automation Capabilities

Many Indian 3PLs select warehouse management system India solutions without considering mobile capabilities and automation readiness, limiting operational efficiency and future growth potential.

Mobile Technology Importance

Real-time visibility: Mobile devices enable real-time inventory tracking and status updates across multi-location warehouse management India operations.

Improved accuracy: Barcode scanning and mobile data entry reduce manual errors and improve inventory accuracy.

Enhanced productivity: Workers can access system information and complete tasks without returning to fixed terminals.

Automation Readiness

The future of Indian warehouse operations lies in automation. Discover the latest technologies in warehousing logistics in India and how they’re transforming 3PL operations across the country:

Robotic process automation: Integration with picking robots and automated sorting systems

IoT connectivity: Support for IoT warehouse management India devices like sensors, RFID tags, and smart shelving

AI-powered analytics: AI powered WMS India capabilities for demand forecasting and optimization

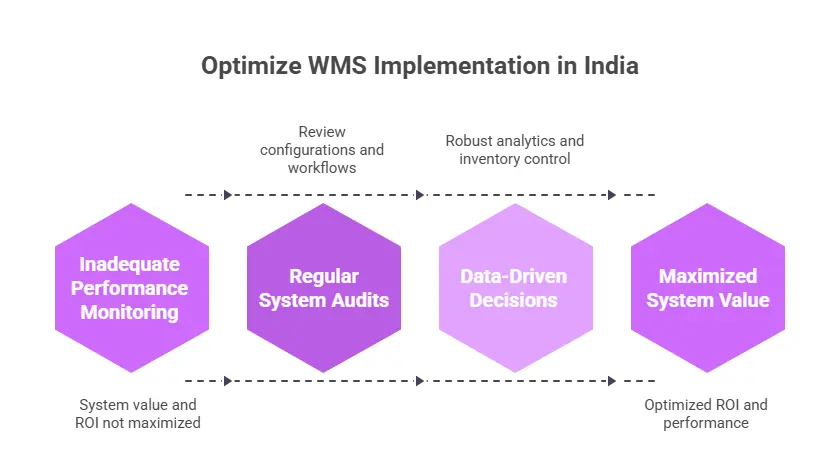

Mistake #6: Inadequate Performance Monitoring and Optimization

Many 3PLs implement their WMS implementation India and assume the work is done. However, continuous monitoring and optimization are crucial for maximizing system value and ROI.

Key Performance Indicators to Track

Operational metrics:

- Order accuracy rates

- Pick and pack productivity

- Inventory accuracy

- Order fulfillment cycle times

Financial metrics:

- Cost per order processed

- Labor productivity improvements

- Inventory carrying cost reductions

- Customer satisfaction scores

Optimization Strategies

Regular system audits:

- Review system configurations and workflows

- Identify bottlenecks and improvement opportunities

- Update processes based on business changes

Data-driven decision making requires robust analytics and proper inventory control methods. Learn about effective inventory control methods for Indian businesses to optimize your warehouse operations and maximize ROI.

Industry-Specific Considerations for Indian 3PLs

Different industries require specialized approaches to 3PL warehouse management system India implementation.

E-commerce Fulfillment

Ecommerce fulfillment WMS India requirements include:

- Multi-channel inventory management

- Real-time stock updates across platforms

- Return merchandise authorization (RMA) handling

- Peak season scalability

FMCG Distribution

FMCG warehouse management India needs focus on high-volume processing and batch and expiry tracking in FMCG operations, promotional pricing support, and regional distribution optimization.

Pharmaceutical Logistics

Pharmaceutical 3PL WMS India must address temperature monitoring, batch tracking, and regulatory compliance. For detailed insights, explore our guide on pharmaceutical warehouse management systems and industry-specific requirements.

Emerging Trends in Indian WMS Technology

Understanding future trends helps 3PLs make forward-thinking decisions. Explore the future of warehouse management trends 2025 to stay ahead of technological developments and market changes.

Cloud-Based Solutions

Cloud WMS solutions India offer several advantages:

- Lower upfront costs and faster implementation

- Automatic updates and maintenance

- Better scalability for growing businesses

- Enhanced security and disaster recovery

Artificial Intelligence and Machine Learning

AI powered WMS India capabilities include:

- Predictive analytics for demand forecasting

- Intelligent inventory optimization

- Automated exception handling

- Dynamic resource allocation

Blockchain Integration

Blockchain logistics India applications provide:

- Enhanced traceability and transparency

- Reduced fraud and counterfeiting

- Improved supplier verification

- Smart contract automation

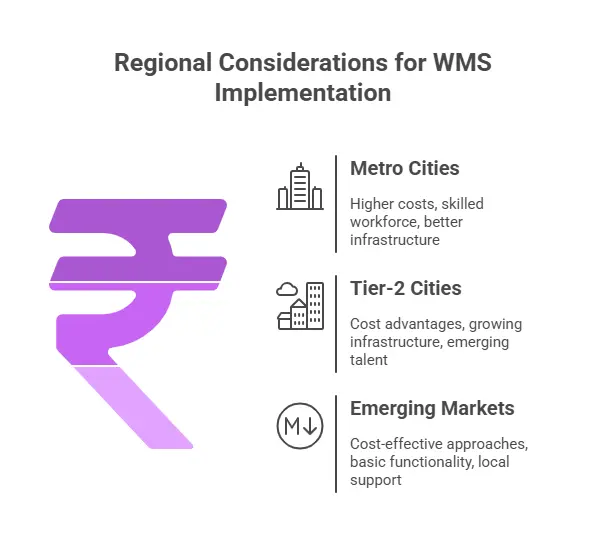

Regional Implementation Considerations

Warehouse management system India implementations must consider regional variations across the country.

Metro Cities (Mumbai, Delhi, Bangalore)

WMS solutions Mumbai and other metro areas face:

- Higher real estate costs requiring space optimization

- Skilled workforce availability

- Better infrastructure and connectivity

- Higher customer expectations

Tier-2 Cities (Pune, Chennai, Hyderabad)

Warehouse management Bangalore and similar cities offer:

- Cost advantages for operations

- Growing infrastructure development

- Emerging talent pools

- Government incentives for logistics hubs

Emerging Markets

Logistics solutions Ahmedabad and other developing markets require:

- Cost-effective implementation approaches

- Basic functionality focus initially

- Local language support

- Simplified user interfaces

Cost Optimization Strategies

WMS implementation cost India can vary significantly based on approach and vendor selection.

Total Cost of Ownership Analysis

Consider all cost components:

- Software licensing fees

- Implementation and customization costs

- Training and change management expenses

- Ongoing maintenance and support

- Hardware and infrastructure requirements

ROI Calculation Framework

How to calculate WMS ROI for Indian 3PL operations:

- Quantify current operational inefficiencies

- Estimate productivity improvements

- Calculate cost savings from reduced errors

- Factor in customer satisfaction improvements

- Consider scalability benefits for future growth

Leading Indian 3PLs report an average ROI of 250-300% within 24 months of successful WMS implementation, with the biggest gains coming from reduced labor costs and improved inventory accuracy.

Building a Future-Ready WMS Strategy

Successful 3PL technology mistakes India avoidance requires a strategic approach to system selection and implementation.

Long-term Planning Considerations

Technology roadmap alignment:

- Ensure chosen system supports future technology adoption

- Plan for integration with emerging technologies

- Consider vendor’s innovation roadmap

Business growth planning:

- Select systems that can scale with business growth

- Plan for multi-location expansion capabilities

- Consider international expansion requirements

Vendor Partnership Approach

Choose vendors who understand Indian market:

- Local presence and support capabilities

- Understanding of regulatory requirements

- Experience with similar 3PL implementations

- Commitment to ongoing innovation

Conclusion

Avoiding these common WMS selection India mistakes requires careful planning, thorough evaluation, and strategic thinking. The Indian logistics technology landscape offers numerous opportunities for 3PLs willing to invest in the right warehouse management system India solutions.

Success depends on understanding your specific business requirements, evaluating vendors thoroughly, planning for proper implementation and change management, and continuously optimizing your systems for maximum value.

The future belongs to 3PLs who embrace logistics digitization India while avoiding the pitfalls that have derailed many implementations. By learning from these common mistakes and following proven best practices, your organization can achieve the operational excellence and competitive advantage that modern WMS solutions promise.

Ready to transform your 3PL operations with the right WMS solution? Start by conducting a comprehensive assessment of your current challenges and requirements. Consider partnering with experienced third party logistics software India vendors who understand the unique needs of Indian 3PL operations and can guide you through a successful implementation journey.

Frequently Asked Questions (FAQs)

Top 3PL WMS India solutions include SAP Extended Warehouse Management, Oracle WMS Cloud, Manhattan Associates, and innovative platforms like OmneelabWMS that offer specialized Indian 3PL features. The choice depends on your specific requirements, budget, and industry focus. Consider factors like GST compliant WMS India capabilities, local support, and integration options when making your selection.

WMS implementation cost India ranges from ₹15-50 lakhs for SMEs to ₹1-5 crores for large enterprises. Cloud solutions like OmneelabWMS offer cost-effective alternatives starting at ₹2-8 lakhs, making advanced WMS accessible to smaller 3PLs without compromising functionality. Consider total cost of ownership including training, customization, and ongoing support.

Essential GST integration WMS India features include automatic tax calculations, e-way bill generation, GSTR reporting, and GSTN portal integration. Key requirements include handling different tax rates based on product categories, managing interstate transactions, supporting reverse charge mechanisms, and maintaining proper documentation for audit purposes.

Cloud WMS solutions India offer faster deployment, lower costs, and automatic updates. Most Indian 3PLs prefer cloud platforms for their scalability and multi-location warehouse management India capabilities without heavy IT infrastructure investments. On-premise solutions provide more control but require higher initial investment and internal IT resources.

Key challenges include GST compliance, workforce training across skill levels, system integration, and regional language support. Major challenges include ensuring GST compliant WMS India functionality, managing change with diverse workforce skill levels, integrating with existing systems, handling multiple regional languages, and selecting vendors with strong local support.

People also read:

- WMS for Tata CLiq

- WMS for Snapdeal

- WMS for Nykaa

- JioMart WMS Integration

- Inventory Management with Barcode Technology

- Common Inventory Management Challenges

Kapil Pathak is a Senior Digital Marketing Executive with over four years of experience specializing in the logistics and supply chain industry. His expertise spans digital strategy, search engine optimization (SEO), search engine marketing (SEM), and multi-channel campaign management. He has a proven track record of developing initiatives that increase brand visibility, generate qualified leads, and drive growth for D2C & B2B technology companies.