Have you ever wondered why some businesses struggle with cash flow despite strong sales? The answer often lies in inventory management mistakes that silently drain profits. Poor inventory control can cost businesses up to 25% of their annual revenue, yet many companies continue making the same costly errors year after year.

Whether you’re running a small retail operation or managing a large warehouse, inventory management problems can quickly spiral out of control. From stockouts that frustrate customers to overstock situations that tie up valuable capital, these mistakes have real financial consequences.

In this comprehensive guide, we’ll explore the 11 most costly inventory errors that businesses make and provide actionable solutions to help you avoid them. By the end of this article, you’ll have a clear roadmap for implementing inventory management best practices that protect your bottom line.

Why Inventory Management Mistakes Are So Expensive

Before diving into specific mistakes, let’s understand why inventory control errors hit businesses so hard financially. Poor inventory management affects multiple areas of your business simultaneously:

- Cash flow disruption from tied-up capital in excess stock

- Lost sales due to stockouts and poor customer experience

- Increased storage costs from inefficient space utilization

- Product obsolescence leading to write-offs and markdowns

- Labor inefficiencies from manual processes and error correction

Research shows that businesses with effective inventory management see 15-20% higher profit margins compared to those with poor practices. Now, let’s examine the specific mistakes that prevent companies from achieving these results.

1. Relying on Manual Inventory Processes

One of the most significant warehouse management mistakes is sticking with manual inventory tracking when your business has outgrown spreadsheets. Manual processes lead to human errors, inconsistent data entry, and time-consuming reconciliation efforts.

The Real Cost: Companies using manual inventory processes experience error rates of 20-40%, compared to less than 1% with automated systems.

How to Avoid This Mistake:

- Implement barcode scanning systems for accurate data capture

- Consider RFID inventory tracking for real-time visibility

- Invest in inventory management software that integrates with your existing systems

- Train staff on proper cycle counting procedures to maintain accuracy

Pro Tip: Start with basic automation in high-volume areas before expanding company-wide. This approach helps justify the investment while building internal expertise.

2. Poor Demand Forecasting and Planning

Demand forecasting errors rank among the most expensive supply chain mistakes businesses make. When you can’t predict customer demand accurately, you either overstock (tying up capital) or understock (losing sales).

Many businesses rely on gut feelings or simple historical averages instead of sophisticated forecasting methods. This approach fails to account for seasonality, market trends, and external factors that influence demand.

Solutions for Better Demand Forecasting:

- Use statistical forecasting models that consider multiple variables

- Implement ABC inventory analysis to prioritize forecasting efforts

- Monitor inventory turnover ratio to identify slow-moving items

- Collaborate with sales and marketing teams for better demand insights

Real-World Example: A retail client improved forecast accuracy by 35% simply by incorporating weather data into their demand planning for seasonal products.

3. Inadequate Safety Stock Management

Setting inappropriate safety stock levels is a common mistake that leads to either excessive carrying costs or frequent stockouts. Many businesses use arbitrary percentages or copy competitors without considering their unique circumstances.

The Challenge: Balancing the cost of holding extra inventory against the risk of stockouts requires careful analysis of demand variability, supplier reliability, and customer expectations.

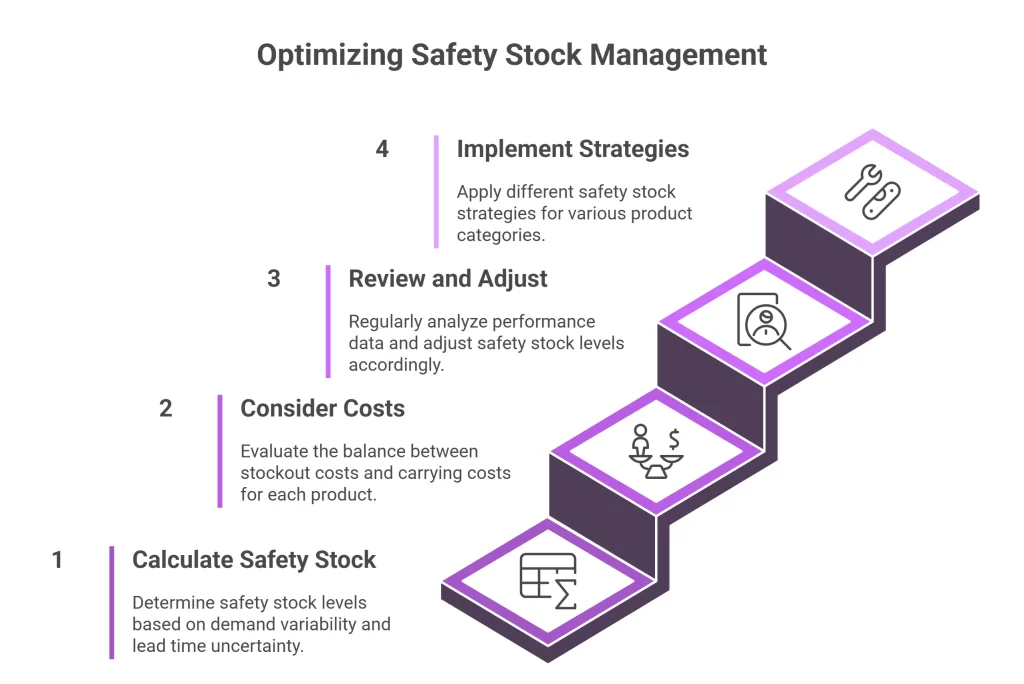

Optimizing Safety Stock Levels:

- Calculate safety stock based on demand variability and lead time uncertainty

- Consider the cost of stockouts versus carrying costs for each product

- Regularly review and adjust safety stock levels based on performance data

- Implement different safety stock strategies for different product categories

4. Ignoring Inventory Carrying Costs

Many businesses focus solely on purchase prices while ignoring the true cost of carrying inventory. These hidden costs can represent 20-30% of inventory value annually and include:

- Storage and warehouse costs

- Insurance and taxes

- Obsolescence and shrinkage

- Capital costs and opportunity costs

Reducing Inventory Carrying Costs:

- Calculate total carrying costs for accurate profitability analysis

- Implement just-in-time inventory principles where appropriate

- Negotiate better payment terms with suppliers

- Optimize warehouse layout for efficient space utilization

5. Lack of Real-Time Inventory Visibility

Poor inventory visibility across multiple locations, channels, and systems creates a cascade of problems. Without accurate, real-time data, businesses make decisions based on outdated information, leading to stock management errors.

Common Visibility Problems:

- Disconnected systems that don’t communicate

- Delayed inventory updates

- Lack of visibility into in-transit inventory

- Poor tracking of inventory across multiple locations

Improving Inventory Visibility:

- Implement integrated warehouse management system benefits

- Use cloud-based solutions for real-time data access

- Establish standard procedures for inventory updates

- Create dashboards for key inventory management KPIs

Studies show that 72% of Indian retailers lack real-time inventory visibility across all channels, leading companies to lose an average of ₹52 lakh annually due to poor inventory tracking and missed sales opportunities during peak festival seasons (Source: Retail Association of India (RAI) Digital Commerce Report, 2024).

6. Inadequate Supplier Relationship Management

Supplier relationship management problems can create significant inventory tracking mistakes. Poor communication, unreliable suppliers, and lack of backup options lead to supply disruptions and emergency ordering at premium prices.

Strengthening Supplier Relationships:

- Develop strategic partnerships with key suppliers

- Implement supplier performance scorecards

- Maintain backup suppliers for critical items

- Negotiate flexible terms that accommodate demand changes

Key Insight: Companies with strong supplier relationships experience 50% fewer supply disruptions and 15% lower procurement costs.

7. Failing to Address Dead Stock and Obsolescence

Dead stock management is often overlooked until it becomes a major problem. Obsolete inventory ties up capital, occupies valuable warehouse space, and eventually requires costly disposal or markdown.

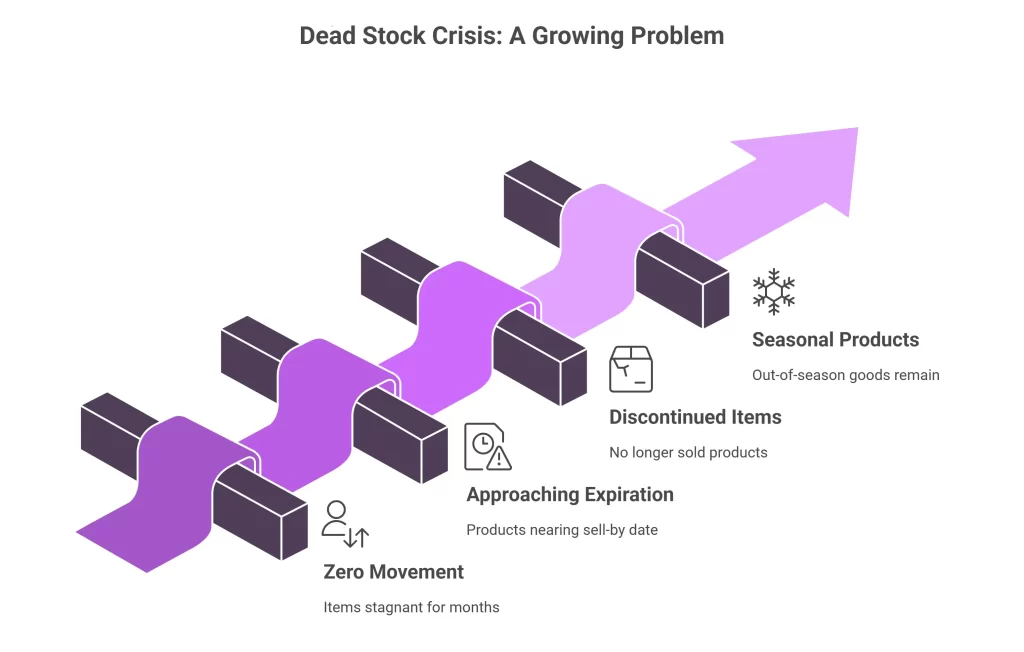

Warning Signs of Poor Dead Stock Management:

- Items with zero movement for 6+ months

- Products approaching expiration dates

- Discontinued items still in inventory

- Seasonal products carried year-round

Preventing and Managing Dead Stock:

- Implement regular inventory aging reports

- Create markdown strategies for slow-moving items

- Improve demand forecasting to prevent overordering

- Establish clear policies for discontinuing products

8. Inconsistent Inventory Auditing Practices

How often should you conduct inventory audits? This common question reveals a fundamental misunderstanding. Effective inventory management requires continuous monitoring, not just annual physical counts.

Inconsistent auditing leads to inaccurate inventory data, making it impossible to identify and correct problems before they become expensive.

Implementing Effective Audit Procedures:

- Conduct regular cycle counting procedures instead of relying on annual counts

- Use statistical sampling for large inventories

- Investigate and resolve discrepancies immediately

- Track audit results to identify systemic problems

9. Poor Integration Between Systems

In today’s connected business environment, inventory management solutions must integrate seamlessly with other business systems. Poor integration creates data silos, duplicate entry, and reconciliation nightmares.

Common Integration Problems:

- Disconnected POS and inventory systems

- Manual data transfers between systems

- Inconsistent product information across platforms

- Delayed synchronization causing stockouts

Achieving Better System Integration:

- Choose solutions with robust API capabilities

- Implement middleware for legacy system connections

- Establish data governance standards

- Regular testing of integration points

10. Neglecting Seasonal and Trend Analysis

Failing to account for seasonal patterns and market trends leads to costly inventory errors during peak and off-peak periods. Many businesses order the same quantities year-round, ignoring predictable demand fluctuations.

Mastering Seasonal Inventory Management:

- Analyze historical sales data for seasonal patterns

- Adjust safety stock levels based on seasonal demand

- Plan promotional activities around inventory levels

- Coordinate with suppliers for seasonal capacity

11. Inadequate Staff Training and Accountability

The most sophisticated automated inventory systems won’t prevent mistakes if staff aren’t properly trained. Human errors in receiving, picking, and data entry can quickly undermine even the best inventory management processes.

Training Areas Often Overlooked:

- Proper use of inventory management software

- Understanding of inventory policies and procedures

- Recognition of common error patterns

- Importance of data accuracy

Building a Skilled Inventory Team:

- Provide comprehensive inventory management training

- Establish clear accountability measures

- Create standard operating procedures

- Regular performance reviews and feedback

The Path Forward: Implementing Inventory Management Best Practices

Avoiding these inventory management mistakes requires a systematic approach to warehouse optimization and supply chain optimization. Start by assessing your current processes and identifying the most costly problems first.

Implementation Priorities:

- Automate manual processes to reduce errors and improve efficiency

- Improve demand forecasting through better data and analytics

- Optimize inventory levels based on true carrying costs and service requirements

- Enhance visibility through integrated systems and real-time reporting

- Strengthen supplier relationships for more reliable supply chains

Measuring Success: Key Performance Indicators

Track these inventory management KPIs to measure improvement:

- Inventory accuracy percentage (target: 95%+)

- Inventory turnover ratio (varies by industry)

- Stockout frequency (target: <2%)

- Carrying cost as percentage of inventory value (target: <25%)

- Order fulfillment accuracy (target: 99%+)

Research indicates that 78% of Indian companies implementing automated inventory systems see ROI within 8-10 months, while businesses with optimized inventory management achieve 98% order accuracy compared to just 89% with manual systems, particularly crucial during high-demand periods like Diwali and wedding seasons (Source: IBM).

Conclusion: Transform Your Inventory Management Today

Inventory management problems don’t have to drain your profits. By recognizing and addressing these 11 costly mistakes, you can transform your inventory operations from a cost center into a competitive advantage.

Remember, how to avoid inventory mistakes isn’t just about implementing new technology—it’s about creating a culture of continuous improvement where accuracy, efficiency, and customer satisfaction drive every decision.

The businesses that thrive in today’s competitive environment are those that master the fundamentals of inventory management while leveraging technology to scale their operations efficiently.

Ready to eliminate costly inventory mistakes? Start by conducting an honest assessment of your current processes using this guide as a checklist. Identify your biggest pain points and develop an action plan to address them systematically.

Frequently Asked Questions

Small businesses typically struggle with manual inventory processes, poor demand forecasting, and relying on spreadsheets instead of proper inventory management software. The most expensive mistake is failing to track true inventory carrying costs, which can represent 20-30% of inventory value annually.

Inventory control errors reduce profitability through tied-up capital in excess stock, lost sales from stockouts, increased labor costs, and supply chain inefficiencies. Businesses with effective inventory management achieve 15-20% higher profit margins than those with poor practices.

Stockouts occur when demand exceeds inventory, causing lost sales and customer dissatisfaction. Overstock involves excess inventory that ties up capital and increases obsolescence risk. Both are costly, making accurate demand forecasting essential.

Implement continuous cycle counting procedures rather than annual counts. Count high-value items monthly, medium-value quarterly, and low-value annually. This approach maintains 95%+ inventory accuracy with minimal business disruption.

Technology reduces inventory tracking mistakes through automation and real-time visibility. RFID inventory tracking and barcode scanning systems eliminate manual errors, while inventory management software provides demand forecasting and automated reordering for better accuracy and cost control.

Kapil Pathak is a Senior Digital Marketing Executive with over four years of experience specializing in the logistics and supply chain industry. His expertise spans digital strategy, search engine optimization (SEO), search engine marketing (SEM), and multi-channel campaign management. He has a proven track record of developing initiatives that increase brand visibility, generate qualified leads, and drive growth for D2C & B2B technology companies.